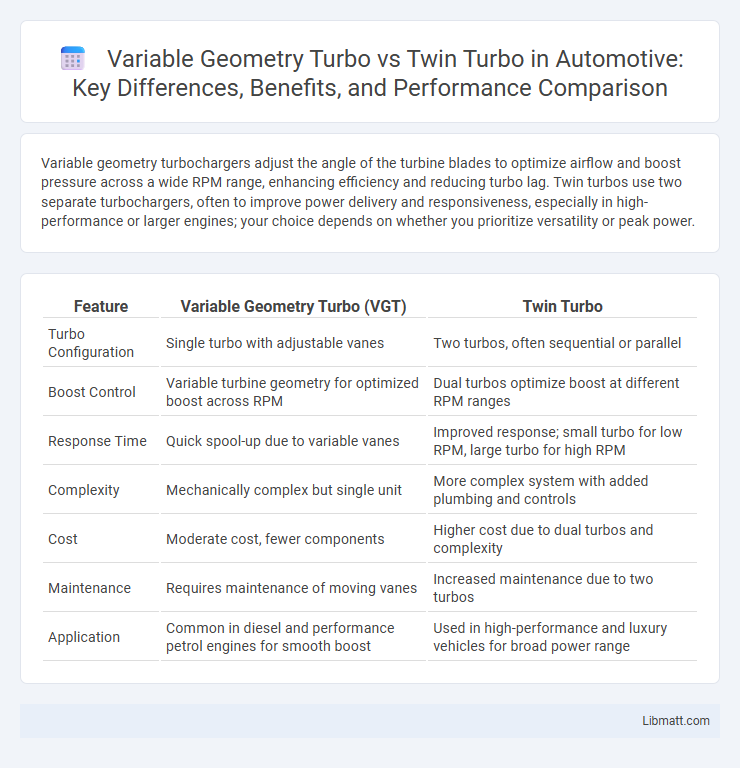

Variable geometry turbochargers adjust the angle of the turbine blades to optimize airflow and boost pressure across a wide RPM range, enhancing efficiency and reducing turbo lag. Twin turbos use two separate turbochargers, often to improve power delivery and responsiveness, especially in high-performance or larger engines; your choice depends on whether you prioritize versatility or peak power.

Table of Comparison

| Feature | Variable Geometry Turbo (VGT) | Twin Turbo |

|---|---|---|

| Turbo Configuration | Single turbo with adjustable vanes | Two turbos, often sequential or parallel |

| Boost Control | Variable turbine geometry for optimized boost across RPM | Dual turbos optimize boost at different RPM ranges |

| Response Time | Quick spool-up due to variable vanes | Improved response; small turbo for low RPM, large turbo for high RPM |

| Complexity | Mechanically complex but single unit | More complex system with added plumbing and controls |

| Cost | Moderate cost, fewer components | Higher cost due to dual turbos and complexity |

| Maintenance | Requires maintenance of moving vanes | Increased maintenance due to two turbos |

| Application | Common in diesel and performance petrol engines for smooth boost | Used in high-performance and luxury vehicles for broad power range |

Introduction to Turbocharging Technologies

Variable geometry turbos (VGT) adjust the turbine's vanes to optimize airflow and boost pressure across different engine speeds, enhancing efficiency and reducing lag. Twin turbo systems use two separate turbochargers, either in parallel or sequentially, to provide better power delivery and improved performance at various RPM ranges. Your choice between VGT and twin turbo impacts engine responsiveness and fuel efficiency depending on driving conditions and performance goals.

What is Variable Geometry Turbo (VGT)?

Variable Geometry Turbo (VGT) is a type of turbocharger featuring adjustable vanes that control exhaust gas flow to optimize boost pressure across different engine speeds. This design enhances engine efficiency and reduces turbo lag by varying the turbine's aspect ratio. Unlike twin turbo systems, which use two separate turbochargers, VGT relies on a single, adaptable unit for more precise boost management and improved performance.

Exploring Twin Turbo Systems

Twin turbo systems utilize two separate turbochargers to reduce turbo lag and increase engine efficiency by optimizing airflow at different RPM ranges. This setup allows smaller turbos to spool quickly at low speeds while larger ones take over at higher RPM, enhancing performance across a wide power band. Compared to variable geometry turbos, twin turbos provide more precise boost control and flexibility, especially for high-performance engines seeking maximum power output.

Key Differences: VGT vs Twin Turbo

Variable Geometry Turbo (VGT) uses adjustable vanes inside the turbine housing to optimize exhaust flow and boost pressure across a wide RPM range, improving throttle response and efficiency. Twin Turbo systems employ two separate turbochargers, either in parallel or sequential setups, to reduce turbo lag and increase power output by dividing exhaust flow or staging boost at different RPMs. Your choice between VGT and Twin Turbo depends on whether you prioritize seamless boost control (VGT) or higher peak performance and tuning flexibility (Twin Turbo).

Performance Comparison: Acceleration and Power Delivery

Variable geometry turbos (VGT) provide more consistent power delivery across a wide RPM range by adjusting turbine geometry, enhancing acceleration and reducing turbo lag compared to traditional twin-turbo setups. Twin turbos often offer higher peak power due to their ability to operate two smaller turbines simultaneously, benefiting top-end acceleration but may suffer from less seamless boost response at lower RPMs. Your choice between VGT and twin turbo should consider whether you prioritize quick throttle response and smooth power curve or maximum peak performance for acceleration bursts.

Efficiency and Fuel Economy Aspects

Variable geometry turbos enhance fuel economy by adjusting the turbine's vanes to optimize boost pressure across engine speeds, leading to improved combustion efficiency and reduced turbo lag. Twin turbos use two separate turbochargers to deliver quicker spool times and higher power output but often result in higher fuel consumption due to increased complexity and potential for less efficient air management. Efficiency gains from variable geometry turbos typically translate into better fuel economy compared to twin turbo setups, especially in real-world driving conditions where variable load demands prevail.

Reliability and Maintenance Considerations

Variable geometry turbos offer improved reliability due to fewer moving parts compared to twin-turbo systems, reducing the likelihood of mechanical failures. Twin turbochargers require more complex maintenance because they consist of two separate units, increasing potential points of failure and service costs. Your choice should factor in the ease of maintenance and long-term durability, especially if minimizing downtime is a priority.

Cost Implications: Installation and Long-Term Ownership

Variable geometry turbos typically have higher upfront installation costs due to their complex design and advanced control systems, but they offer improved fuel efficiency and reduced emissions, potentially lowering long-term ownership expenses. Twin turbo setups involve added costs from installing two separate turbochargers and more intricate plumbing, which can increase maintenance and repair expenses over time. Overall, the choice between variable geometry and twin turbo systems should consider initial investment against expected performance benefits and ongoing maintenance costs.

Use Cases: Ideal Applications for Each System

Variable geometry turbochargers excel in applications requiring quick spool-up and efficient boost control, making them ideal for everyday road cars and light trucks with fluctuating engine loads. Twin turbo systems are better suited for high-performance vehicles and heavy-duty applications, delivering higher peak power and improved top-end response by spreading the turbocharging workload between two smaller turbos. Understanding your vehicle's power demands and driving conditions will help you choose the best turbo setup for optimal performance.

Which Turbo System is Better for You?

Variable geometry turbochargers (VGT) offer precise boost control by adjusting turbine vanes, providing excellent low-end torque and fuel efficiency, ideal for daily driving and varying engine loads. Twin turbo systems use two smaller turbos to reduce lag and increase power across a broader RPM range, making them better suited for high-performance or racing applications. Choosing between VGT and twin turbo depends on your priority: efficiency and smooth power delivery favor VGT, while maximum performance and quicker boost response align with twin turbo setups.

variable geometry turbo vs twin turbo Infographic

libmatt.com

libmatt.com