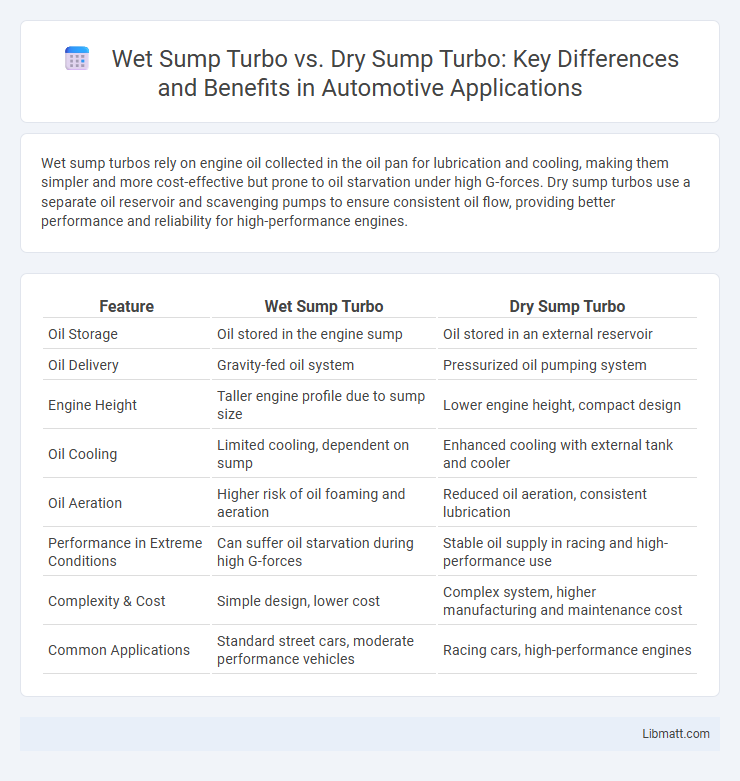

Wet sump turbos rely on engine oil collected in the oil pan for lubrication and cooling, making them simpler and more cost-effective but prone to oil starvation under high G-forces. Dry sump turbos use a separate oil reservoir and scavenging pumps to ensure consistent oil flow, providing better performance and reliability for high-performance engines.

Table of Comparison

| Feature | Wet Sump Turbo | Dry Sump Turbo |

|---|---|---|

| Oil Storage | Oil stored in the engine sump | Oil stored in an external reservoir |

| Oil Delivery | Gravity-fed oil system | Pressurized oil pumping system |

| Engine Height | Taller engine profile due to sump size | Lower engine height, compact design |

| Oil Cooling | Limited cooling, dependent on sump | Enhanced cooling with external tank and cooler |

| Oil Aeration | Higher risk of oil foaming and aeration | Reduced oil aeration, consistent lubrication |

| Performance in Extreme Conditions | Can suffer oil starvation during high G-forces | Stable oil supply in racing and high-performance use |

| Complexity & Cost | Simple design, lower cost | Complex system, higher manufacturing and maintenance cost |

| Common Applications | Standard street cars, moderate performance vehicles | Racing cars, high-performance engines |

Introduction to Turbocharging Systems

Turbocharging systems enhance engine performance by forcing more air into the combustion chamber, increasing power output and efficiency. Wet sump turbos rely on traditional oil pans for lubrication and cooling, making them simpler and more cost-effective for everyday applications. Dry sump turbos use an external oil reservoir and scavenging pumps to maintain consistent oil flow under high-performance conditions, minimizing oil starvation and improving reliability in motorsports and extreme driving scenarios.

Understanding Wet Sump Turbo Systems

Wet sump turbo systems utilize a single oil reservoir located in the engine's oil pan, where oil is pumped directly to the turbocharger for lubrication and cooling. This setup simplifies maintenance and reduces system complexity but may lead to oil starvation during high-G cornering or aggressive driving due to oil sloshing. Wet sump turbos are commonly found in street vehicles where cost-effectiveness and packaging efficiency are prioritized over extreme performance demands.

Exploring Dry Sump Turbo Systems

Dry sump turbo systems utilize external oil reservoirs and scavenging pumps to prevent oil starvation during high-performance driving, enhancing reliability in motorsport applications. These systems improve engine lubrication under extreme conditions by maintaining consistent oil pressure and reducing oil aeration compared to wet sump setups. Their design allows for better engine placement and weight distribution, optimizing overall vehicle performance and turbocharger efficiency.

Key Differences Between Wet and Dry Sump Turbos

Wet sump turbos use engine oil from a single reservoir at the bottom of the engine, providing simpler design and lower cost but are prone to oil starvation during high lateral acceleration. Dry sump turbos employ an external oil reservoir combined with a scavenging pump system, ensuring consistent oil pressure and lubrication even under extreme cornering and hard braking conditions found in racing or high-performance applications. The primary difference lies in oil management strategies, affecting reliability, performance, and suitability for various driving environments.

Performance Implications: Wet Sump vs Dry Sump

Wet sump turbo systems generally provide simpler oil management but can suffer from oil starvation during high-G cornering, reducing performance consistency. Dry sump turbo setups use external oil reservoirs and scavenging pumps, ensuring stable oil pressure and improved engine reliability under extreme driving conditions. Your vehicle's performance will benefit from a dry sump turbo in high-performance or racing applications due to superior lubrication and thermal management.

Maintenance and Reliability Considerations

Wet sump turbos are generally easier to maintain due to their simpler oil delivery system, but they can suffer from oil starvation during high-performance driving or aggressive cornering. Dry sump turbos offer enhanced reliability by using an external oil reservoir and pump system, which ensures consistent lubrication and reduces oil aeration, making them ideal for high-stress or racing applications. Your choice between these systems should consider maintenance accessibility and long-term durability under your specific driving conditions.

Wet Sump Turbo: Pros and Cons

Wet sump turbos offer a simpler design with integrated oil reservoirs that facilitate efficient lubrication and cooling, reducing engine complexity and maintenance costs. However, they are prone to oil starvation during high G-force conditions, which can lead to turbo damage and reduced performance in demanding driving scenarios. The susceptibility to oil foaming and contamination also limits their effectiveness in extreme racing or off-road applications where consistent oil pressure is critical.

Dry Sump Turbo: Pros and Cons

Dry sump turbo systems offer superior oil control and reduced risk of oil starvation during high-performance driving, making them ideal for racing and track applications. They provide consistent lubrication, improved engine reliability, and allow for lower engine placement to enhance vehicle handling. However, dry sump turbos are more complex, costly to install and maintain, and require additional space and equipment compared to wet sump systems.

Choosing the Right System for Your Application

Selecting between a wet sump turbo and a dry sump turbo depends on your engine's design and performance goals. Wet sump turbos are more common in standard applications, providing simpler installation and cost-effectiveness, while dry sump turbos excel in high-performance or racing engines by ensuring consistent oil pressure and reducing oil starvation during extreme conditions. Evaluating your vehicle's operating environment, oil management needs, and space constraints will help you determine the most suitable turbo setup for your application.

Final Verdict: Wet Sump Turbo vs Dry Sump Turbo

The final verdict between wet sump turbo and dry sump turbo systems depends on engine performance goals and application requirements. Wet sump turbos offer simpler design and lower cost, making them suitable for everyday driving and moderate performance enhancements. Dry sump turbos provide superior oil control and cooling, ideal for high-performance engines subjected to extreme conditions or sustained high G-forces.

Wet Sump Turbo vs Dry Sump Turbo Infographic

libmatt.com

libmatt.com