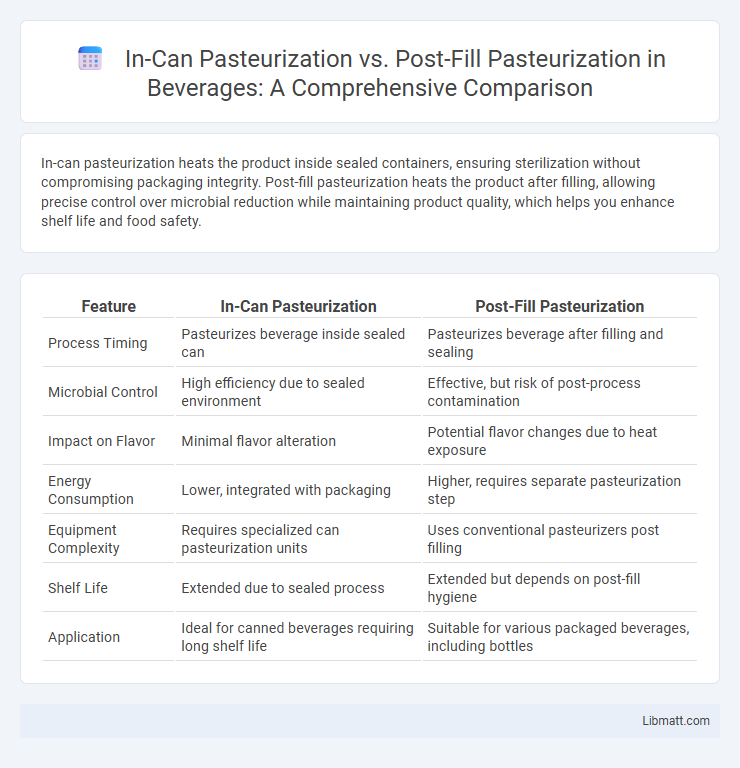

In-can pasteurization heats the product inside sealed containers, ensuring sterilization without compromising packaging integrity. Post-fill pasteurization heats the product after filling, allowing precise control over microbial reduction while maintaining product quality, which helps you enhance shelf life and food safety.

Table of Comparison

| Feature | In-Can Pasteurization | Post-Fill Pasteurization |

|---|---|---|

| Process Timing | Pasteurizes beverage inside sealed can | Pasteurizes beverage after filling and sealing |

| Microbial Control | High efficiency due to sealed environment | Effective, but risk of post-process contamination |

| Impact on Flavor | Minimal flavor alteration | Potential flavor changes due to heat exposure |

| Energy Consumption | Lower, integrated with packaging | Higher, requires separate pasteurization step |

| Equipment Complexity | Requires specialized can pasteurization units | Uses conventional pasteurizers post filling |

| Shelf Life | Extended due to sealed process | Extended but depends on post-fill hygiene |

| Application | Ideal for canned beverages requiring long shelf life | Suitable for various packaged beverages, including bottles |

Introduction to Pasteurization in Food and Beverage Processing

Pasteurization in food and beverage processing enhances safety by eliminating harmful microorganisms through controlled heat treatment. In-can pasteurization involves heating products inside sealed containers, preserving quality and extending shelf life without post-packaging contamination risks. Post-fill pasteurization subjects filled packages to heat, ensuring your products remain safe while maintaining flavor and nutritional value.

What is In-Can Pasteurization?

In-can pasteurization involves heating sealed containers to a specific temperature to eliminate pathogens and extend shelf life without compromising product quality. This method ensures uniform heat distribution within the sealed can, reducing the risk of contamination post-packaging. It is commonly used in the food and beverage industry to preserve products such as soups, sauces, and ready-to-eat meals.

Understanding Post-Fill Pasteurization

Post-fill pasteurization involves heating the product after it has been sealed in its final packaging, ensuring effective microbial inactivation without compromising the container's integrity. This method allows for better control of temperature and time parameters, reducing the risk of product contamination during handling. It is widely used for heat-sensitive beverages and ready-to-drink products to extend shelf life while preserving flavor and nutritional value.

Key Differences Between In-Can and Post-Fill Pasteurization

In-can pasteurization involves sterilizing the product directly within sealed cans, effectively reducing microbial contamination before packaging, while post-fill pasteurization heats the product after it has been filled into its final container, ensuring safety without re-exposing it to contamination. Key differences include in-can pasteurization offering minimal risk of contamination and uniform heat treatment, whereas post-fill pasteurization allows more control over temperature conditions but may require more advanced packaging materials to withstand heat. Your choice between these methods depends on factors like product type, packaging integrity, and desired shelf life.

Thermal Processing Parameters and Efficiency

In-can pasteurization involves heating the product inside sealed containers, ensuring uniform heat distribution with precise control over temperature and time, typically ranging from 70degC to 90degC for 15 to 30 minutes, optimizing microbial inactivation while preserving product quality. Post-fill pasteurization applies heat after filling and sealing, often using tunnel pasteurizers with controlled temperature zones maintaining 60degC to 75degC for 20 to 40 minutes, enhancing efficiency by reducing thermal exposure time and increasing throughput. Thermal processing efficiency in in-can pasteurization relies on container heat transfer properties, whereas post-fill pasteurization benefits from continuous processing and shorter cycle times, influencing overall energy consumption and operational cost.

Impact on Product Quality and Shelf Life

In-can pasteurization preserves product quality by minimizing microbial contamination during packaging, which enhances shelf life without compromising flavor or texture. Post-fill pasteurization, applied after packaging, offers additional microbial control but may cause slight alterations in taste and nutrient content. Your choice between these methods influences product freshness, safety, and longevity based on the specific food or beverage characteristics.

Microbial Safety: In-Can vs Post-Fill Methods

In-can pasteurization ensures microbial safety by effectively sterilizing the product within the sealed can, preventing contamination during packaging and storage. Post-fill pasteurization targets microbial pathogens after the product is filled, typically using methods like hot water or steam treatment to eliminate residual microbes on the container's surface and contents. Understanding the distinctions between these methods helps optimize your food safety protocols by balancing sterilization efficacy and product quality preservation.

Equipment and Technology Requirements

In-can pasteurization requires specialized sealing equipment capable of withstanding high temperatures and pressure during heat treatment inside the sealed container, along with precise temperature control systems to ensure product safety without compromising container integrity. Post-fill pasteurization demands advanced thermal processing tunnels or chambers that uniformly apply heat to already sealed containers, coupled with conveyor systems and sensors for monitoring temperature and humidity to prevent spoilage and maintain quality. Both methods necessitate robust automation and real-time data logging technologies to optimize efficiency, traceability, and compliance with food safety standards.

Cost Analysis and Operational Considerations

In-can pasteurization typically involves higher initial equipment costs due to the need for specialized heating and cooling systems within the canning line, while post-fill pasteurization may reduce upfront expenses but increase operational complexity and energy consumption. Operationally, in-can pasteurization can streamline production by combining sterilization with packaging, enhancing efficiency and reducing contamination risks, whereas post-fill pasteurization requires additional handling steps and precise temperature control after packaging. Your cost analysis should weigh capital investment against long-term savings in energy and labor, considering product sensitivity and throughput requirements to determine the most economical method.

Choosing the Right Pasteurization Method for Your Product

Selecting the ideal pasteurization method depends on product type, sensitivity, and packaging integrity. In-can pasteurization ensures microbial safety by heating sealed containers, preserving flavor and reducing contamination risk, ideal for heat-stable liquids and canned goods. Post-fill pasteurization suits delicate products requiring minimal thermal impact, relying on pasteurizing after filling to maintain freshness while ensuring extended shelf life.

In-can pasteurization vs post-fill pasteurization Infographic

libmatt.com

libmatt.com