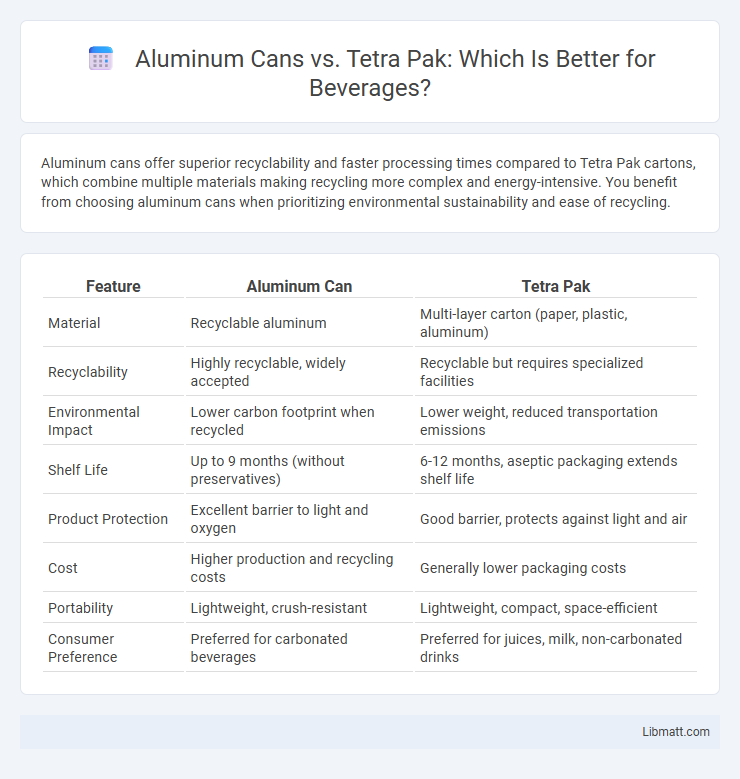

Aluminum cans offer superior recyclability and faster processing times compared to Tetra Pak cartons, which combine multiple materials making recycling more complex and energy-intensive. You benefit from choosing aluminum cans when prioritizing environmental sustainability and ease of recycling.

Table of Comparison

| Feature | Aluminum Can | Tetra Pak |

|---|---|---|

| Material | Recyclable aluminum | Multi-layer carton (paper, plastic, aluminum) |

| Recyclability | Highly recyclable, widely accepted | Recyclable but requires specialized facilities |

| Environmental Impact | Lower carbon footprint when recycled | Lower weight, reduced transportation emissions |

| Shelf Life | Up to 9 months (without preservatives) | 6-12 months, aseptic packaging extends shelf life |

| Product Protection | Excellent barrier to light and oxygen | Good barrier, protects against light and air |

| Cost | Higher production and recycling costs | Generally lower packaging costs |

| Portability | Lightweight, crush-resistant | Lightweight, compact, space-efficient |

| Consumer Preference | Preferred for carbonated beverages | Preferred for juices, milk, non-carbonated drinks |

Introduction to Aluminum Cans and Tetra Pak

Aluminum cans are lightweight, highly recyclable containers widely used for beverages, offering durability and excellent preservation qualities. Tetra Pak cartons combine paperboard, plastic, and aluminum layers to package liquids like milk and juice, emphasizing extended shelf life and sustainability. Both packaging solutions cater to different market needs, balancing convenience, environmental impact, and product protection.

Material Composition and Manufacturing Process

Aluminum cans are primarily composed of aluminum, a lightweight and highly recyclable metal, produced through rolling and stamping processes that shape the metal into cylindrical containers. Tetra Pak cartons consist of multiple layers, including paperboard, polyethylene, and aluminum foil, which are laminated and formed into aseptic packages using heat-sealing techniques to ensure product freshness. Your choice between these packaging types influences recyclability, production energy, and material sustainability due to their distinct compositions and manufacturing methods.

Environmental Impact: Recycling and Sustainability

Aluminum cans have a high recycling rate of about 69%, with recycled aluminum saving up to 95% of the energy compared to producing new aluminum, making them highly sustainable. Tetra Pak cartons, composed of paperboard, plastic, and aluminum layers, pose recycling challenges but are increasingly recycled via specialized facilities, contributing to reducing landfill waste. Both packaging options aim to minimize environmental impact, but aluminum's closed-loop recycling system offers superior sustainability benefits in energy savings and waste reduction.

Cost Analysis: Production and Transportation

Aluminum cans generally incur higher production costs due to energy-intensive smelting but benefit from efficient recycling programs that reduce long-term expenses. Tetra Pak packaging offers lower production costs with lightweight materials that significantly reduce transportation expenses compared to aluminum cans. You can optimize your supply chain costs by balancing the higher production expenses of aluminum against the transportation savings of Tetra Pak cartons.

Barrier Properties and Shelf Life

Aluminum cans offer superior barrier properties due to their impermeability to light, oxygen, and moisture, which significantly extends the shelf life of beverages by preventing oxidation and spoilage. Tetra Pak cartons provide effective protection against light and oxygen with their multi-layered structure, but their barrier performance is slightly less robust, often resulting in shorter shelf life compared to aluminum cans. Shelf life for products in aluminum cans can reach up to 24 months, while Tetra Pak packages typically maintain product freshness for around 6 to 12 months, depending on the beverage type and storage conditions.

Consumer Safety and Health Considerations

Aluminum cans provide robust protection against light and oxygen, reducing the risk of contamination and preserving beverage quality, though concerns about aluminum leaching exist but are generally minimal with proper internal coatings. Tetra Pak cartons use multiple layers, including plastic and aluminum foil, to protect contents from air and bacteria, supporting long shelf life without refrigeration, but may contain BPA in the lining, raising consumer health questions. You should evaluate product type and storage conditions to choose packaging that prioritizes both safety and health.

Packaging Design and Brand Appeal

Aluminum cans offer a sleek, metallic finish that enhances brand visibility and conveys a premium, eco-friendly image, making them highly appealing in retail environments. Tetra Pak packaging provides versatile design options with vibrant, full-color printing on a lightweight, carton-based material that supports brand storytelling through intricate graphics. Your choice between aluminum cans and Tetra Pak should consider the desired shelf impact, consumer perception, and alignment with sustainable packaging trends.

Global Market Trends and Adoption

The global market for aluminum cans is projected to grow significantly, driven by increasing demand in beverage packaging due to superior recyclability and consumer preferences for sustainability. Tetra Pak's market adoption is expanding rapidly in regions prioritizing lightweight packaging with extended shelf life, especially in dairy and liquid food sectors. Market analysts highlight aluminum cans dominating in Western markets, while Tetra Pak sees strong growth in Asia-Pacific and Latin America due to evolving consumer habits and advancements in packaging technology.

Regulatory Compliance and Industry Standards

Aluminum cans meet stringent regulatory compliance requirements such as FDA and EU food contact guidelines, ensuring safety and recyclability within established industry standards like the Can Manufacturers Institute protocols. Tetra Pak packaging adheres to international standards including ISO 9001 and FSC certification, emphasizing sustainable sourcing and compliance with food safety regulations like EFSA and FDA. You benefit from selecting a packaging solution that aligns with relevant environmental and safety regulations tailored to your product's needs.

Future Innovations in Beverage Packaging

Future innovations in beverage packaging focus on enhancing sustainability and functionality, with Aluminum cans advancing lightweight designs and recyclable materials that reduce carbon footprints. Tetra Pak continues to innovate with plant-based cartons and improved aseptic technology to extend shelf life while minimizing environmental impact. Your choice between Aluminum cans and Tetra Pak reflects priorities in recyclability, resource efficiency, and evolving industry standards aimed at reducing waste.

Aluminum can vs Tetra Pak Infographic

libmatt.com

libmatt.com