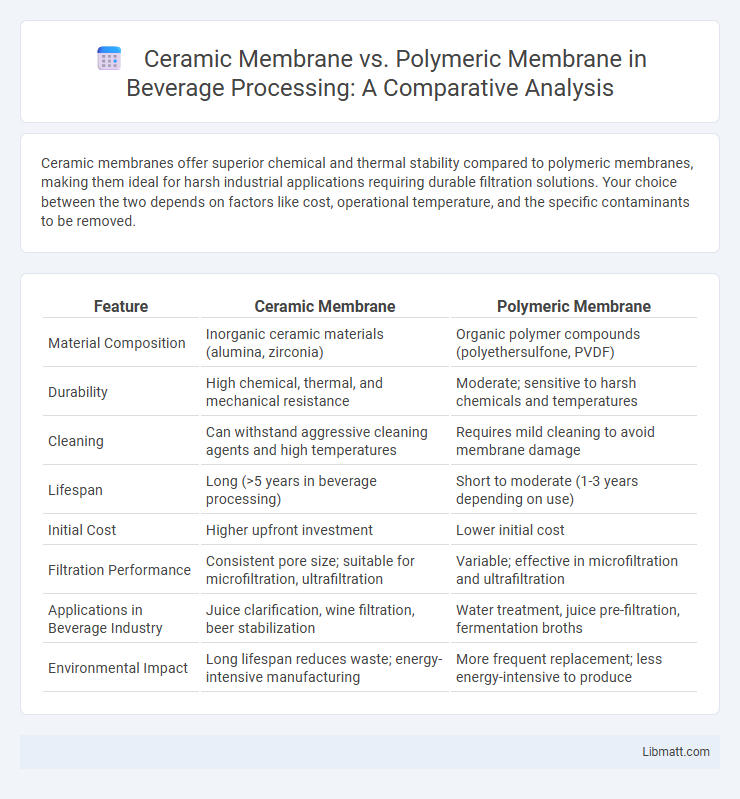

Ceramic membranes offer superior chemical and thermal stability compared to polymeric membranes, making them ideal for harsh industrial applications requiring durable filtration solutions. Your choice between the two depends on factors like cost, operational temperature, and the specific contaminants to be removed.

Table of Comparison

| Feature | Ceramic Membrane | Polymeric Membrane |

|---|---|---|

| Material Composition | Inorganic ceramic materials (alumina, zirconia) | Organic polymer compounds (polyethersulfone, PVDF) |

| Durability | High chemical, thermal, and mechanical resistance | Moderate; sensitive to harsh chemicals and temperatures |

| Cleaning | Can withstand aggressive cleaning agents and high temperatures | Requires mild cleaning to avoid membrane damage |

| Lifespan | Long (>5 years in beverage processing) | Short to moderate (1-3 years depending on use) |

| Initial Cost | Higher upfront investment | Lower initial cost |

| Filtration Performance | Consistent pore size; suitable for microfiltration, ultrafiltration | Variable; effective in microfiltration and ultrafiltration |

| Applications in Beverage Industry | Juice clarification, wine filtration, beer stabilization | Water treatment, juice pre-filtration, fermentation broths |

| Environmental Impact | Long lifespan reduces waste; energy-intensive manufacturing | More frequent replacement; less energy-intensive to produce |

Introduction to Ceramic and Polymeric Membranes

Ceramic membranes are composed of inorganic materials such as alumina, zirconia, or silica, offering exceptional thermal stability, chemical resistance, and mechanical strength, ideal for harsh filtration environments. Polymeric membranes, made from organic polymers like polysulfone, polyethersulfone, or polyvinylidene fluoride, provide flexibility, lower cost, and ease of fabrication but generally have limited durability under extreme conditions. Both membrane types serve critical roles in water treatment, gas separation, and bioprocessing, with material composition directly influencing performance, lifespan, and application suitability.

Key Differences Between Ceramic and Polymeric Membranes

Ceramic membranes exhibit superior chemical, thermal, and mechanical stability compared to polymeric membranes, making them ideal for harsh industrial applications involving high temperatures and aggressive chemicals. Polymeric membranes offer greater flexibility, lower cost, and easier fabrication, which suits them for water treatment, food processing, and biomedical applications. Ceramic membranes typically provide longer service life and can be cleaned more aggressively without degradation, whereas polymeric membranes are prone to fouling and limited cleaning options.

Material Composition and Structure

Ceramic membranes are composed primarily of inorganic materials such as alumina, zirconia, or titania, featuring a rigid, porous structure that withstands high temperatures and aggressive chemical environments. Polymeric membranes consist of organic polymers like polysulfone, polyvinylidene fluoride (PVDF), or polyamide, characterized by flexible, asymmetric or symmetric structures suitable for moderate operating conditions. The inherent material composition and porous architecture directly influence the membranes' chemical resistance, thermal stability, and filtration performance in water treatment and separation processes.

Filtration Performance and Efficiency

Ceramic membranes offer superior filtration performance with higher chemical and thermal stability, enabling efficient separation of fine particles and contaminants under harsh conditions. Polymeric membranes, while more cost-effective, generally provide lower mechanical strength and durability, affecting long-term filtration efficiency in demanding environments. Your choice depends on balancing operational robustness and filtration precision for optimal membrane system performance.

Chemical and Thermal Resistance Comparison

Ceramic membranes exhibit exceptional chemical and thermal resistance, withstanding harsh solvents, strong acids, and temperatures exceeding 400degC, making them ideal for aggressive industrial applications. Polymeric membranes, while more cost-effective and flexible, generally tolerate lower temperatures, typically up to 80-120degC, and are more susceptible to chemical degradation from oxidizing agents and solvents. Your choice depends on the specific chemical environment and thermal demands of the process, prioritizing ceramic membranes for durability under extreme conditions.

Durability and Lifespan

Ceramic membranes offer superior durability and a significantly longer lifespan than polymeric membranes, withstanding high temperatures, chemical corrosion, and abrasive conditions without degrading. Polymeric membranes are more prone to fouling, chemical damage, and mechanical wear, resulting in more frequent replacements and higher maintenance costs. Choosing a ceramic membrane ensures consistent performance and cost-efficiency over time, making it ideal for demanding filtration applications.

Maintenance and Cleaning Requirements

Ceramic membranes require less frequent maintenance due to their chemical and thermal stability, enabling aggressive cleaning methods such as high-temperature steam or strong chemical agents without damage. Polymeric membranes, being more sensitive to harsh chemicals and temperature, demand gentler cleaning protocols and more frequent inspections to prevent fouling and degradation. Optimizing your system's longevity depends on selecting a membrane type aligned with your maintenance capacity and cleaning requirements.

Cost Analysis and Economic Considerations

Ceramic membranes generally have higher upfront costs than polymeric membranes due to materials and manufacturing processes but offer longer lifespans and greater chemical resistance, reducing replacement frequency and maintenance expenses. Polymeric membranes are more affordable initially but may incur higher operational costs over time due to susceptibility to fouling and shorter durability. Your choice should weigh initial investment against long-term savings in maintenance and replacement to optimize economic efficiency.

Typical Applications in Water and Wastewater Treatment

Ceramic membranes excel in high-temperature and chemically aggressive wastewater treatment, making them ideal for industrial applications such as chemical manufacturing, food processing, and pharmaceutical effluent filtration. Polymeric membranes are widely used in municipal water treatment, wastewater reuse, and desalination due to their cost-effectiveness, flexibility, and ease of installation. Both membrane types facilitate microfiltration, ultrafiltration, and nanofiltration processes, but ceramic membranes offer superior durability and resistance to fouling in harsh operational environments.

Future Trends and Innovations in Membrane Technology

Ceramic membranes are gaining traction due to their superior chemical resistance, thermal stability, and longer lifespan, making them ideal for harsh industrial applications and future water treatment technologies. Polymeric membranes continue to evolve with advancements in material science, integrating nanomaterials and bio-inspired modifications to enhance permeability, selectivity, and fouling resistance for cost-effective and scalable solutions. Emerging innovations in membrane technology emphasize hybrid systems that combine ceramic and polymeric components, improving overall efficiency and sustainability in wastewater treatment and gas separation processes.

Ceramic membrane vs polymeric membrane Infographic

libmatt.com

libmatt.com