A tun is a large vessel used for fermentation, allowing yeast to convert sugars into alcohol, while a mash kettle is designed for heating and mixing grains with water to extract fermentable sugars. Your brewing process relies on the mash kettle for creating the wort and the tun for fermenting the beer efficiently.

Table of Comparison

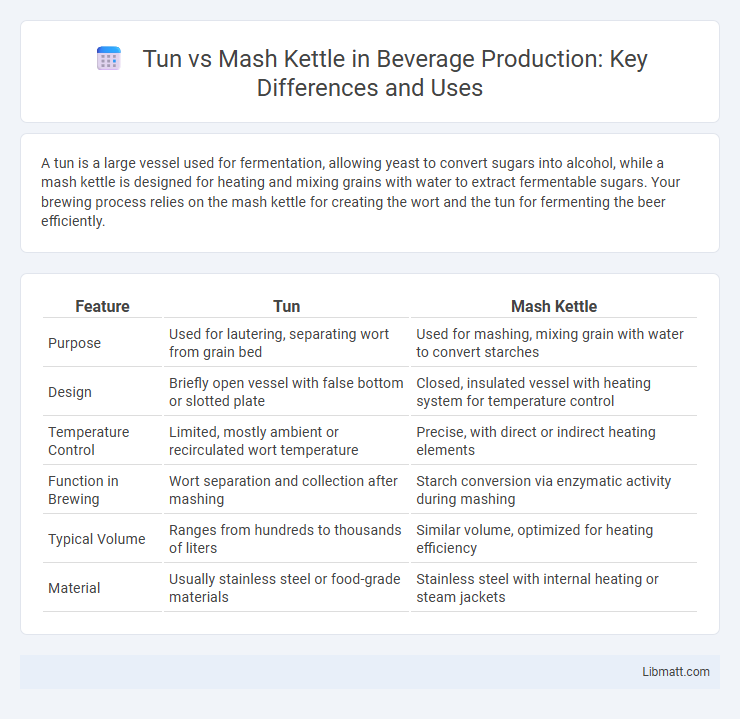

| Feature | Tun | Mash Kettle |

|---|---|---|

| Purpose | Used for lautering, separating wort from grain bed | Used for mashing, mixing grain with water to convert starches |

| Design | Briefly open vessel with false bottom or slotted plate | Closed, insulated vessel with heating system for temperature control |

| Temperature Control | Limited, mostly ambient or recirculated wort temperature | Precise, with direct or indirect heating elements |

| Function in Brewing | Wort separation and collection after mashing | Starch conversion via enzymatic activity during mashing |

| Typical Volume | Ranges from hundreds to thousands of liters | Similar volume, optimized for heating efficiency |

| Material | Usually stainless steel or food-grade materials | Stainless steel with internal heating or steam jackets |

Introduction to Tun and Mash Kettle

A tun is a large vessel designed for fermenting wort into beer, featuring a sealed environment to maintain fermentation conditions. A mash kettle serves as a container where malted grains are mixed with water and heated to convert starches into fermentable sugars during the mashing process. Understanding the distinct roles and functionalities of your tun and mash kettle is essential for efficient brewing operations.

Key Functions of Tun and Mash Kettle

The tun primarily functions as a vessel for mashing grains, where enzymes break down starches into fermentable sugars, while the mash kettle is used to heat and boil the wort after mashing. The mash tun maintains a controlled temperature to optimize enzyme activity during the mashing process, and the mash kettle ensures thorough boiling to sterilize the wort and facilitate hop isomerization for bitterness. Both vessels are essential in brewing, with the mash tun emphasizing enzymatic conversion and the mash kettle focusing on wort concentration and sterilization.

Design Differences: Tun vs Mash Kettle

The primary design difference between a tun and a mash kettle lies in their function and structure: a mash kettle is equipped with heating elements and often a false bottom to facilitate mashing, while a tun is typically a large vessel designed solely for fermenting or mixing without direct heating. Mash kettles have features that promote efficient starch conversion through controlled temperature, whereas tuns prioritize insulation and volume for fermentation or lautering processes. Understanding these design distinctions helps optimize Your brewing setup for either wort preparation or yeast fermentation stages.

Materials Used in Manufacturing

Tun vessels are typically crafted from stainless steel or copper, chosen for their excellent heat conductivity and durability during fermentation. Mash kettles are commonly made from stainless steel or coated carbon steel, providing corrosion resistance and efficient heat distribution crucial for the mashing process. Your choice of vessel material directly impacts heat retention, ease of cleaning, and flavor preservation in brewing or distilling.

Role in the Brewing Process

The tun and mash kettle play distinct roles in the brewing process essential for beer production. The mash tun is where milled grains are combined with hot water to convert starches into fermentable sugars through enzymatic activity. The mash kettle, often integrated as a mash/lauter tun or a separate vessel, facilitates the boiling of wort with hops to extract bitterness, flavor, and aroma while sterilizing the liquid before fermentation.

Temperature Control Mechanisms

Tun vessels typically employ basic temperature control through external jackets or hot water circulation, which can result in less precise regulation during the mashing process. Mash kettles often feature integrated heating elements and advanced thermostats, offering improved temperature stability and uniform heat distribution essential for enzymatic activity in brewing. Enhanced temperature control in mash kettles ensures consistent extraction of sugars and optimal wort quality.

Efficiency and Brewing Outcomes

A mash tun offers superior thermal retention, maintaining stable temperatures that enhance enzymatic activity during mashing, which leads to more consistent starch conversion and improved wort quality. Conversely, a mash kettle provides greater flexibility for all-grain brewing methods that involve both mashing and boiling within the same vessel, potentially reducing equipment needs but risking temperature fluctuations that can impact efficiency. Choosing the right system affects your brewing outcomes by balancing precise temperature control and operational convenience, directly influencing sugar extraction rates and overall beer flavor profiles.

Maintenance and Cleaning Considerations

A mash tun typically requires regular cleaning to remove grain residues and prevent bacterial contamination, using hot water and specialized cleaning agents to maintain optimal performance. Mash kettles demand thorough rinsing after each brew to avoid buildup of hop particles and proteins, with some models featuring built-in cleaning systems to ease the process. Understanding these maintenance differences helps you choose the best equipment for efficient sanitation and long-term durability.

Cost Comparison and Investment Value

Mash tuns typically have a lower initial cost compared to mash kettles due to their simpler design and function. Mash kettles, equipped with advanced heating systems and versatility for boiling and mashing, justify higher investment through increased operational efficiency and product quality. Investing in a mash kettle often results in better long-term value for brewers seeking precise temperature control and multipurpose equipment.

Choosing the Right Equipment for Your Brewery

Selecting the ideal equipment for your brewery hinges on understanding the specific functions of the tun and mash kettle. A mash tun is designed for mixing and holding grains with water at precise temperatures to convert starches into fermentable sugars, while a mash kettle often integrates heating elements for mashing and boiling wort in one vessel. Prioritizing capacity, thermal efficiency, and ease of cleaning ensures optimized brewing performance and product consistency.

Tun vs mash kettle Infographic

libmatt.com

libmatt.com