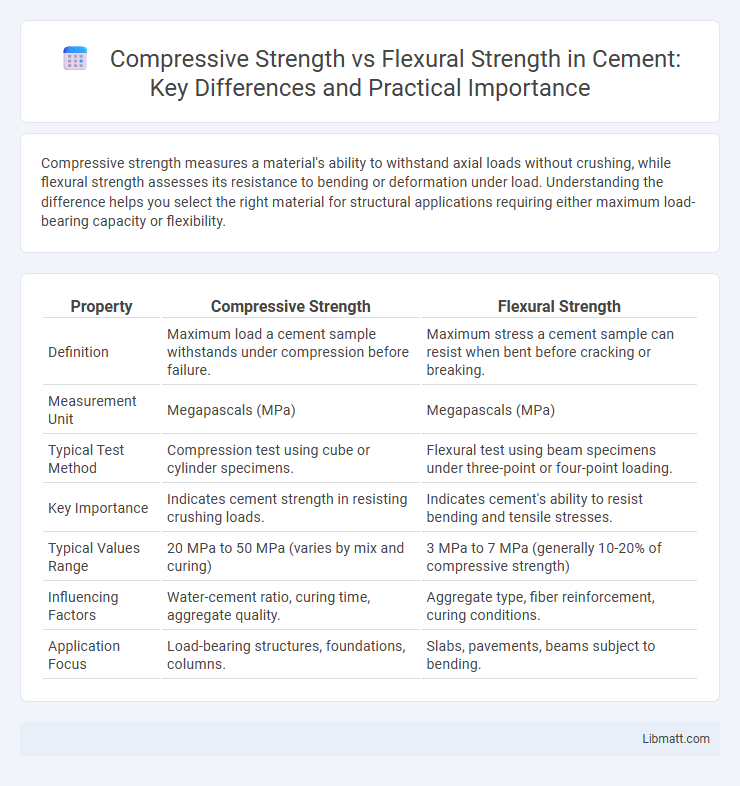

Compressive strength measures a material's ability to withstand axial loads without crushing, while flexural strength assesses its resistance to bending or deformation under load. Understanding the difference helps you select the right material for structural applications requiring either maximum load-bearing capacity or flexibility.

Table of Comparison

| Property | Compressive Strength | Flexural Strength |

|---|---|---|

| Definition | Maximum load a cement sample withstands under compression before failure. | Maximum stress a cement sample can resist when bent before cracking or breaking. |

| Measurement Unit | Megapascals (MPa) | Megapascals (MPa) |

| Typical Test Method | Compression test using cube or cylinder specimens. | Flexural test using beam specimens under three-point or four-point loading. |

| Key Importance | Indicates cement strength in resisting crushing loads. | Indicates cement's ability to resist bending and tensile stresses. |

| Typical Values Range | 20 MPa to 50 MPa (varies by mix and curing) | 3 MPa to 7 MPa (generally 10-20% of compressive strength) |

| Influencing Factors | Water-cement ratio, curing time, aggregate quality. | Aggregate type, fiber reinforcement, curing conditions. |

| Application Focus | Load-bearing structures, foundations, columns. | Slabs, pavements, beams subject to bending. |

Understanding Compressive Strength

Compressive strength measures the ability of a material, such as concrete or metal, to withstand axial loads that push and compact it without crushing. It is a critical factor in construction and engineering, determining how well structures can support heavy weights and resist deformation under pressure. Your knowledge of compressive strength ensures the selection of appropriate materials for safety and durability in building projects.

Defining Flexural Strength

Flexural strength, also known as modulus of rupture, measures a material's ability to resist deformation under load, specifically its capacity to withstand bending forces before failure. It reflects tensile strength in the outer fibers of a beam subjected to bending, which is critical for structural applications where bending stresses dominate. Unlike compressive strength, which quantifies resistance to crushing forces, flexural strength addresses stresses in tension combined with compression, providing essential insight into material performance in beams, slabs, and bridges.

Key Differences Between Compressive and Flexural Strength

Compressive strength measures a material's ability to withstand axial loads that push or compress it, while flexural strength evaluates its capacity to resist bending forces that cause tension and compression simultaneously. Compressive strength tests typically involve forces applied perpendicular to the surface, critical for structural elements like columns and foundations, whereas flexural strength tests are essential for beams and slabs subjected to bending. Understanding these key differences helps you select appropriate materials and design techniques based on specific load conditions and performance requirements.

Importance of Compressive Strength in Material Selection

Compressive strength is a critical property in material selection as it determines a material's ability to withstand axial loads without failure, directly influencing structural integrity and safety. Unlike flexural strength, which measures resistance to bending, compressive strength is essential for components subjected to heavy loads such as columns, foundations, and load-bearing walls. Accurate assessment of compressive strength ensures the durability and performance of construction materials under real-world stress conditions.

Significance of Flexural Strength in Structural Design

Flexural strength is a critical parameter in structural design as it measures a material's ability to withstand bending and tensile stresses, which are common in beams, slabs, and other load-bearing components. Unlike compressive strength, which quantifies resistance to crushing forces, flexural strength ensures the durability and safety of structures subjected to bending moments and lateral loads. Understanding your material's flexural strength helps optimize design choices for enhanced performance and longevity under real-world conditions.

Factors Affecting Compressive and Flexural Strength

Compressive strength is influenced by factors such as concrete mix composition, curing conditions, and aggregate size, which impact the material's ability to withstand axial loads. Flexural strength depends on variables like fiber reinforcement, curing duration, and the presence of microcracks, affecting resistance to bending stresses. Understanding these factors helps you optimize material properties for specific structural requirements.

Testing Methods for Compressive Strength

Compressive strength testing is typically conducted using a universal testing machine (UTM) that applies axial load to a cylindrical or cubic specimen until failure, measuring the maximum load sustained. Standard methods such as ASTM C39 and ISO 1920 prescribe specimen dimensions, loading rates, and environmental conditions to ensure accurate and repeatable results. This test evaluates the material's ability to withstand axial forces, crucial for structural components subjected to compression.

Testing Methods for Flexural Strength

Flexural strength testing typically involves a three-point or four-point bending test, where a specimen is loaded until failure to measure its ability to resist deformation under load. This method evaluates the material's behavior under stress, highlighting its tensile strength on the outer fibers and providing critical insight beyond compressive strength alone. Understanding your material's flexural strength through these tests helps predict performance in real-world structural applications subject to bending forces.

Applications Where Compressive vs Flexural Strength Matters

Compressive strength is crucial in construction elements subjected to heavy loads such as columns, foundations, and pavements, where resistance to crushing forces ensures structural integrity. Flexural strength plays a vital role in applications like beams, slabs, and bridge decks, where materials must resist bending and tensile stresses without cracking. Engineers select materials based on these strengths to optimize safety and performance in infrastructure, automotive components, and aerospace structures.

Choosing the Right Material Based on Strength Requirements

Compressive strength measures a material's ability to withstand axial loads without failure, making it critical for structural components like columns and foundations. Flexural strength, the capacity to resist bending forces, is essential for beams, slabs, and other elements subjected to bending stresses. Selecting materials with high compressive strength suits load-bearing applications, while those with superior flexural strength are ideal for components exposed to bending and tension.

Compressive Strength vs Flexural Strength Infographic

libmatt.com

libmatt.com