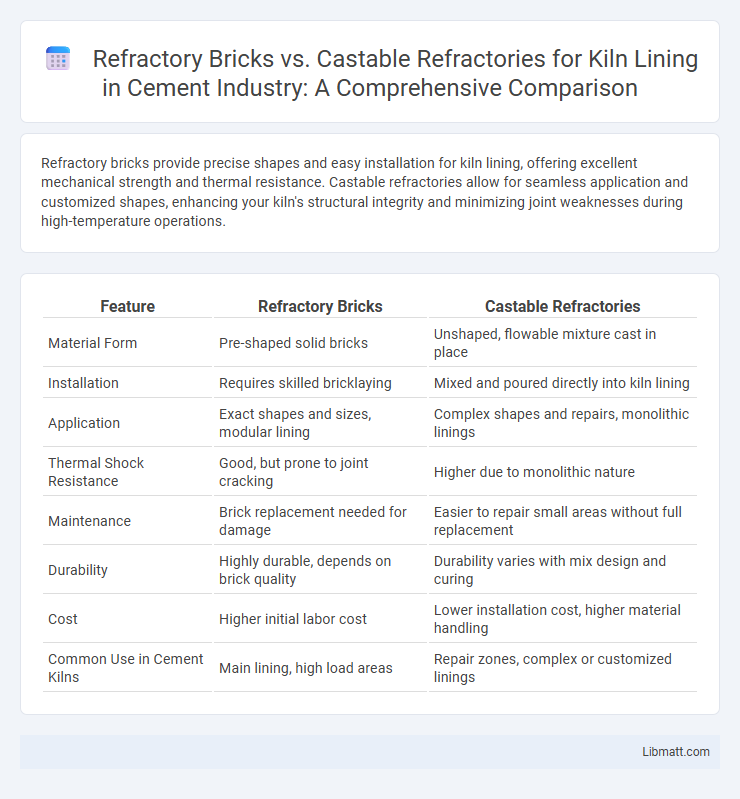

Refractory bricks provide precise shapes and easy installation for kiln lining, offering excellent mechanical strength and thermal resistance. Castable refractories allow for seamless application and customized shapes, enhancing your kiln's structural integrity and minimizing joint weaknesses during high-temperature operations.

Table of Comparison

| Feature | Refractory Bricks | Castable Refractories |

|---|---|---|

| Material Form | Pre-shaped solid bricks | Unshaped, flowable mixture cast in place |

| Installation | Requires skilled bricklaying | Mixed and poured directly into kiln lining |

| Application | Exact shapes and sizes, modular lining | Complex shapes and repairs, monolithic linings |

| Thermal Shock Resistance | Good, but prone to joint cracking | Higher due to monolithic nature |

| Maintenance | Brick replacement needed for damage | Easier to repair small areas without full replacement |

| Durability | Highly durable, depends on brick quality | Durability varies with mix design and curing |

| Cost | Higher initial labor cost | Lower installation cost, higher material handling |

| Common Use in Cement Kilns | Main lining, high load areas | Repair zones, complex or customized linings |

Introduction to Kiln Lining Materials

Refractory bricks and castable refractories serve as essential kiln lining materials, providing high-temperature resistance and structural integrity in industrial furnaces. Refractory bricks offer precise shapes and thermal stability, making them ideal for applications requiring uniformity and ease of installation, while castable refractories provide a versatile, monolithic lining that can be molded to complex shapes and repaired with minimal downtime. Both materials optimize kiln performance by withstanding extreme temperatures, chemical corrosion, and mechanical stress encountered during thermal processing.

What Are Refractory Bricks?

Refractory bricks, also known as firebricks, are heat-resistant materials manufactured from refractory ceramic compounds designed to withstand high temperatures in kiln linings and furnaces. These bricks exhibit high thermal stability, mechanical strength, and resistance to thermal shock, making them essential for maintaining structural integrity in industrial heating processes. Refractory bricks provide reliable insulation and protect kiln walls from extreme heat, chemical corrosion, and mechanical wear, ensuring efficient thermal management in high-temperature applications.

Overview of Castable Refractories

Castable refractories consist of a pre-mixed blend of refractory aggregates, binders, and additives that can be molded or poured into kiln linings, providing seamless coverage and reducing joint-related failures common in refractory bricks. These materials offer high thermal stability, excellent abrasion resistance, and ease of installation, making them ideal for complex shapes and repairs in high-temperature environments. Their ability to form monolithic linings enhances durability and thermal efficiency compared to traditional refractory bricks, which require precise fitting and mortar joints.

Key Differences: Bricks vs. Castables

Refractory bricks offer precise shapes and high structural stability, making them ideal for kiln lining where consistent thermal performance is essential. Castable refractories provide flexible application in complex shapes and quick installation, allowing seamless coverage without joints typical in brick installations. Your choice depends on the kiln's operational demands, with bricks favored for long-term durability and castables for adaptability and faster repairs.

Thermal Performance Comparison

Refractory bricks offer superior thermal insulation due to their dense, uniform structure, providing consistent heat resistance and durability in kiln lining applications. Castable refractories enable customized shapes and seamless joints, enhancing thermal shock resistance but may have slightly lower insulating properties compared to bricks. Your choice depends on balancing thermal performance with flexibility in design and installation requirements.

Installation Processes and Challenges

Refractory bricks require precise manual placement and mortar application during kiln lining installation, demanding skilled labor to ensure proper alignment and joint sealing for thermal efficiency. Castable refractories involve mixing and casting the refractory material directly into place, offering faster installation but posing challenges in achieving uniform density and avoiding shrinkage cracks. Your choice impacts maintenance: bricks allow straightforward replacement of damaged units, while castables require more comprehensive repairs if cracking or spalling occurs.

Durability and Maintenance Considerations

Refractory bricks offer superior durability with high resistance to thermal shock and mechanical wear, making them ideal for long-term kiln lining applications requiring minimal maintenance. Castable refractories provide flexibility in application and seamless lining but may require more frequent inspections and maintenance due to potential cracking or erosion under intense operating conditions. Choosing the right material for Your kiln lining depends on balancing the durability needs with maintenance capabilities to optimize operational efficiency.

Cost Analysis: Bricks vs. Castables

Refractory bricks generally offer lower initial installation costs compared to castable refractories due to their pre-formed shapes and ease of manual placement, reducing labor time. Castable refractories, while sometimes more expensive upfront, provide superior durability and lower maintenance costs over the kiln's operational lifespan, improving overall cost efficiency. Your choice between bricks and castables should factor in both immediate expenses and long-term performance in kiln lining applications.

Suitability for Various Kiln Applications

Refractory bricks offer high durability and are ideal for kiln linings requiring precise shapes and uniform heat distribution, especially in high-temperature zones prone to mechanical stress. Castable refractories provide flexibility for complex kiln geometries and quick installation, making them suitable for repairs and areas with irregular surfaces or lower mechanical demands. Your choice between these materials should consider kiln design, thermal cycling, and maintenance requirements to optimize performance and longevity.

Choosing the Right Lining for Your Kiln

Refractory bricks offer high mechanical strength and precise shapes, making them ideal for areas with intense thermal shock and mechanical wear in kiln lining. Castable refractories provide versatile application and faster installation, conforming to complex shapes and reducing downtime during kiln repairs. Your choice between refractory bricks and castable refractories depends on specific kiln operating conditions, thermal cycles, and maintenance requirements to ensure optimal durability and performance.

Refractory bricks vs Castable refractories (kiln lining) Infographic

libmatt.com

libmatt.com