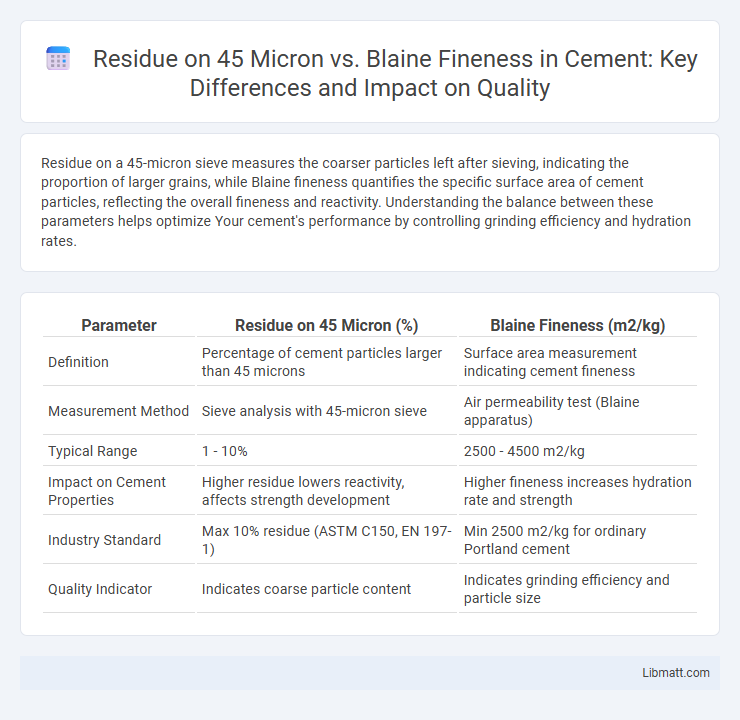

Residue on a 45-micron sieve measures the coarser particles left after sieving, indicating the proportion of larger grains, while Blaine fineness quantifies the specific surface area of cement particles, reflecting the overall fineness and reactivity. Understanding the balance between these parameters helps optimize Your cement's performance by controlling grinding efficiency and hydration rates.

Table of Comparison

| Parameter | Residue on 45 Micron (%) | Blaine Fineness (m2/kg) |

|---|---|---|

| Definition | Percentage of cement particles larger than 45 microns | Surface area measurement indicating cement fineness |

| Measurement Method | Sieve analysis with 45-micron sieve | Air permeability test (Blaine apparatus) |

| Typical Range | 1 - 10% | 2500 - 4500 m2/kg |

| Impact on Cement Properties | Higher residue lowers reactivity, affects strength development | Higher fineness increases hydration rate and strength |

| Industry Standard | Max 10% residue (ASTM C150, EN 197-1) | Min 2500 m2/kg for ordinary Portland cement |

| Quality Indicator | Indicates coarse particle content | Indicates grinding efficiency and particle size |

Introduction to Cement Fineness Parameters

Residue on 45 micron and Blaine fineness are key parameters measuring cement particle size distribution and specific surface area, respectively, which directly influence cement hydration and strength development. Residue on 45 micron quantifies the proportion of particles larger than 45 microns, affecting setting time and workability, while Blaine fineness assesses the total surface area accessible for water-cement reactions, impacting early strength gain and durability. Optimizing both parameters ensures balanced performance characteristics in cement formulations, critical for structural integrity and long-term durability.

Understanding 45 Micron Residue

45 micron residue measures the percentage of particles retained on a 45-micron sieve, indicating the coarser fraction in a powder sample compared to Blaine fineness, which quantifies the specific surface area of finer particles. A higher 45 micron residue suggests lower fineness, impacting cement hydration rates and strength development, whereas Blaine fineness directly correlates with surface area available for chemical reactions. Optimizing particle size distribution by balancing 45 micron residue and Blaine fineness enhances material performance in construction applications.

Overview of Blaine Fineness Measurement

Blaine fineness measurement quantifies the specific surface area of cement particles, expressed in cm2/g, indicating how finely ground the material is and directly impacting cement hydration and strength development. Residue on a 45-micron sieve assesses the percentage of coarser particles remaining, serving as a complementary metric to Blaine fineness by highlighting particle size distribution. Understanding the relationship between these parameters helps optimize your cement's performance by balancing fineness and particle retention.

Key Differences: 45 Micron Residue vs Blaine Fineness

The key differences between 45 micron residue and Blaine fineness lie in their measurement methods and implications for cement particle size distribution. 45 micron residue quantifies the percentage of particles retained on a 45-micron sieve, indicating coarser particles, while Blaine fineness measures the specific surface area of cement in cm2/g, reflecting the overall surface area available for hydration. Understanding these differences helps optimize Your cement quality by balancing fineness for strength development and workability.

Impact on Cement Properties and Performance

Residue on 45 micron and Blaine fineness significantly influence cement properties and performance by determining particle size distribution and surface area. Higher residue on 45 micron indicates coarser particles, leading to slower hydration rates and reduced early strength development, while greater Blaine fineness enhances reactivity and accelerates strength gain. Your choice of cement with optimized fineness parameters directly affects workability, setting time, and long-term durability of concrete structures.

Testing Methods for 45 Micron Residue and Blaine Fineness

Testing methods for 45 micron residue typically involve sieve analysis, where a sample is passed through a 45-micron mesh to measure the percentage of particles retained, providing insights into coarse particle distribution. Blaine fineness is determined using an air permeability apparatus that measures the specific surface area of cement particles, indicating the material's fineness and influencing hydration rate. Your choice of testing method depends on whether particle size distribution (45 micron residue) or surface area and reactivity (Blaine fineness) are the critical parameters for quality control.

Advantages and Limitations of 45 Micron Residue

The 45 micron residue test offers a practical measure of particle size distribution in cement, indicating the proportion of coarse particles that affect strength and setting time. Its advantages include simplicity, rapid assessment, and direct correlation with concrete durability and workability, making it essential for quality control in cement production. Limitations involve its inability to capture finer particles that Blaine fineness measures, which affects overall surface area and hydration rate predictions, thus requiring complementary use with Blaine fineness for comprehensive cement characterization.

Pros and Cons of Blaine Air Permeability Test

The Blaine Air Permeability Test measures cement fineness by assessing air flow through a powder bed, providing quick and repeatable results essential for quality control. Compared to residue on a 45-micron sieve, Blaine fineness offers more precise data on surface area but may be influenced by particle shape and packing density, potentially leading to variability. Your choice depends on whether you prioritize detailed surface area analysis or a straightforward particle size cutoff, balancing accuracy with operational simplicity.

Industrial Relevance and Application Scenarios

Residue on 45 micron and Blaine fineness are key parameters in assessing cement particle size, crucial for optimizing industrial processes such as concrete production and mortar application. Residue on 45 micron measures coarse particles affecting early strength and workability, while Blaine fineness indicates surface area impacting hydration rate and final strength development. Understanding these metrics allows you to tailor cement properties for specific applications like high-performance concrete or rapid-setting materials.

Best Practices for Fineness Optimization in Cement Manufacturing

Optimizing cement fineness involves balancing residue on 45 micron sieve and Blaine fineness values to enhance hydration and strength development. Maintaining residue below 10% on the 45 micron sieve ensures sufficient particle size distribution, while achieving Blaine fineness between 3500 and 4500 cm2/g promotes optimal reactivity. Implementing precise grinding control and regular fineness testing improves energy efficiency and product consistency in cement manufacturing.

Residue on 45 micron vs Blaine fineness Infographic

libmatt.com

libmatt.com