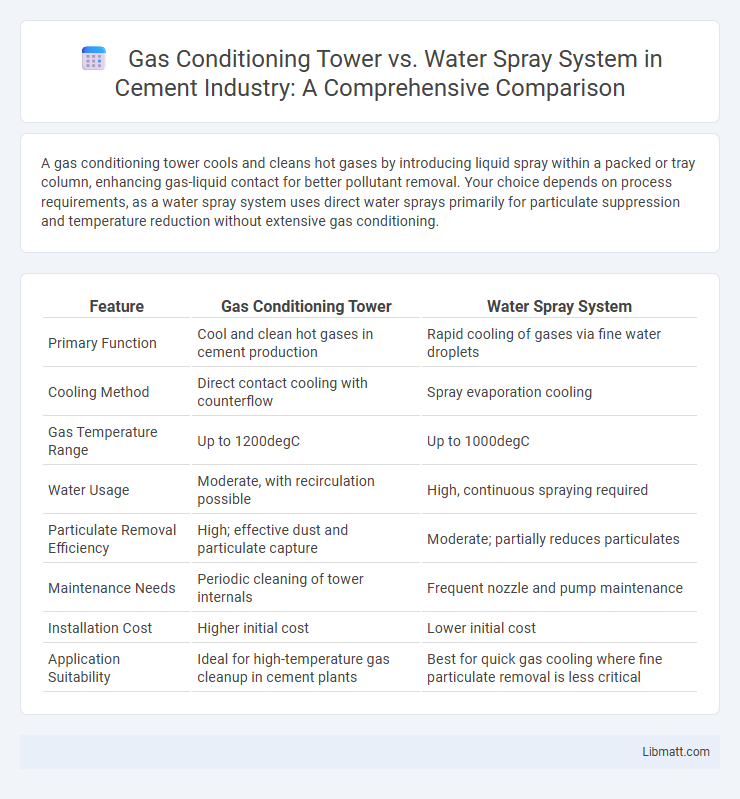

A gas conditioning tower cools and cleans hot gases by introducing liquid spray within a packed or tray column, enhancing gas-liquid contact for better pollutant removal. Your choice depends on process requirements, as a water spray system uses direct water sprays primarily for particulate suppression and temperature reduction without extensive gas conditioning.

Table of Comparison

| Feature | Gas Conditioning Tower | Water Spray System |

|---|---|---|

| Primary Function | Cool and clean hot gases in cement production | Rapid cooling of gases via fine water droplets |

| Cooling Method | Direct contact cooling with counterflow | Spray evaporation cooling |

| Gas Temperature Range | Up to 1200degC | Up to 1000degC |

| Water Usage | Moderate, with recirculation possible | High, continuous spraying required |

| Particulate Removal Efficiency | High; effective dust and particulate capture | Moderate; partially reduces particulates |

| Maintenance Needs | Periodic cleaning of tower internals | Frequent nozzle and pump maintenance |

| Installation Cost | Higher initial cost | Lower initial cost |

| Application Suitability | Ideal for high-temperature gas cleanup in cement plants | Best for quick gas cooling where fine particulate removal is less critical |

Introduction to Gas Conditioning in Industrial Processes

Gas conditioning towers regulate temperature and humidity of industrial gases to optimize downstream processing and protect equipment from corrosion and fouling. Water spray systems, a common method within gas conditioning, use fine water droplets to cool hot gases and remove particulate matter through direct contact. Effective gas conditioning enhances operational efficiency and environmental compliance by controlling gas properties before emission or further treatment.

Overview of Gas Conditioning Towers

Gas conditioning towers are essential components in industrial processes designed to cool, humidify, or clean gas streams by passing them through a packed or tray-filled tower where contact with liquid removes particulates or adjusts temperature and moisture content. Unlike water spray systems that inject water droplets directly into gas streams for rapid cooling or dust suppression, gas conditioning towers provide more controlled mass transfer and enhanced contact time for efficient gas treatment. Understanding your gas stream's specific requirements helps determine whether a gas conditioning tower or a water spray system best optimizes performance and operational efficiency.

Overview of Water Spray Systems

Water spray systems function as critical components in industrial gas treatment by cooling, humidifying, or cleaning gas streams through fine water droplet sprays. These systems efficiently reduce gas temperature and remove particulates or soluble pollutants, enhancing overall emission control and process performance. Your choice between a gas conditioning tower and a water spray system depends on specific operational needs, but water spray systems offer simplicity and flexibility in handling varying gas compositions.

Key Components and Working Principles

A Gas Conditioning Tower primarily consists of a packed bed, spray nozzles, and demisters, designed to cool and saturate gas streams by direct contact with water, enhancing the removal of particulates and soluble gases. In contrast, a Water Spray System uses high-pressure sprays or fogging nozzles to atomize water droplets into the gas flow, relying on evaporation and cooling without a packed section. Understanding these key components and working principles helps you optimize the selection for efficient gas cooling or pollutant removal in industrial processes.

Efficiency in Dust and Temperature Control

Gas conditioning towers excel in temperature control by cooling and saturating hot gas streams, enhancing gas processing efficiency and protecting downstream equipment. Water spray systems are highly effective for dust suppression, capturing airborne particulates and reducing emissions in industrial environments. You can optimize environmental performance by combining both systems to balance efficient temperature regulation and comprehensive dust control.

Water Consumption and Environmental Impact

Gas conditioning towers consume significantly more water than water spray systems, often requiring a continuous flow to cool and clean gases effectively. Water spray systems minimize water usage by employing targeted sprays that optimize droplet size and coverage, reducing overall water consumption. Your choice between these systems directly influences environmental impact, with water spray systems offering a more sustainable solution by lowering water waste and reducing the risk of contaminated runoff.

Installation and Maintenance Requirements

Gas conditioning towers require extensive installation involving large structural components and complex piping systems, resulting in higher initial setup time and costs compared to water spray systems. Maintenance of gas conditioning towers involves regular inspection of packing materials, ensuring proper corrosion resistance, and handling potential fouling, which demands specialized skills and scheduled downtime. Water spray systems offer simpler installation with modular spray nozzles and minimal piping, while their maintenance mainly includes nozzle cleaning and replacement, leading to lower operational costs and easier upkeep.

Operational Costs Comparison

Gas conditioning towers generally have lower operational costs than water spray systems due to reduced water consumption and minimal maintenance requirements. Water spray systems incur higher expenses from frequent nozzle replacements, increased water usage, and potential corrosion issues that elevate upkeep efforts. Your choice between the two will impact long-term operational budgets depending on site-specific conditions and maintenance capabilities.

Suitability for Various Industrial Applications

Gas conditioning towers are highly suitable for industries requiring precise control of gas temperature and humidity, such as power plants and petrochemical refineries. Water spray systems excel in environments where rapid temperature reduction and particulate suppression are needed, making them ideal for steel mills and cement factories. Selecting between these systems depends on factors like gas composition, temperature requirements, and pollutant load.

Choosing the Right Solution: Factors to Consider

Selecting between a gas conditioning tower and a water spray system depends on key factors such as gas composition, temperature control requirements, and pollutant removal efficiency. Gas conditioning towers offer enhanced contact surface area ideal for precise temperature and moisture adjustments in large industrial gases, while water spray systems excel in simpler cooling and particulate scrubbing applications with lower operational complexity. Operational costs, maintenance frequency, and environmental regulations also influence the choice, ensuring optimal performance and compliance in specific industrial contexts.

Gas conditioning tower vs Water spray system Infographic

libmatt.com

libmatt.com