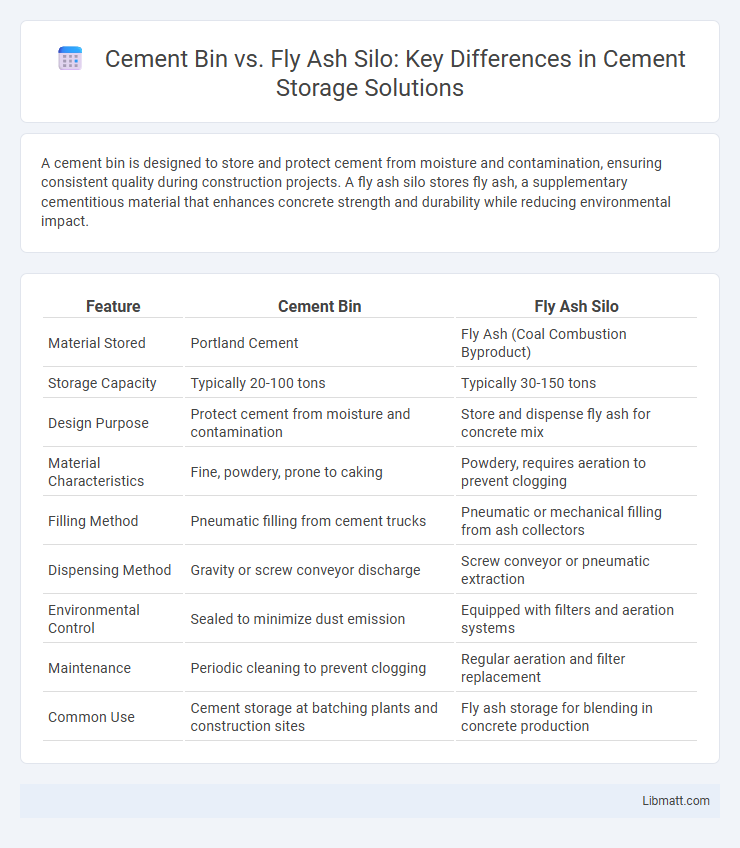

A cement bin is designed to store and protect cement from moisture and contamination, ensuring consistent quality during construction projects. A fly ash silo stores fly ash, a supplementary cementitious material that enhances concrete strength and durability while reducing environmental impact.

Table of Comparison

| Feature | Cement Bin | Fly Ash Silo |

|---|---|---|

| Material Stored | Portland Cement | Fly Ash (Coal Combustion Byproduct) |

| Storage Capacity | Typically 20-100 tons | Typically 30-150 tons |

| Design Purpose | Protect cement from moisture and contamination | Store and dispense fly ash for concrete mix |

| Material Characteristics | Fine, powdery, prone to caking | Powdery, requires aeration to prevent clogging |

| Filling Method | Pneumatic filling from cement trucks | Pneumatic or mechanical filling from ash collectors |

| Dispensing Method | Gravity or screw conveyor discharge | Screw conveyor or pneumatic extraction |

| Environmental Control | Sealed to minimize dust emission | Equipped with filters and aeration systems |

| Maintenance | Periodic cleaning to prevent clogging | Regular aeration and filter replacement |

| Common Use | Cement storage at batching plants and construction sites | Fly ash storage for blending in concrete production |

Introduction to Cement Bins and Fly Ash Silos

Cement bins store dry cement in bulk, ensuring a consistent supply for concrete production and construction projects, while fly ash silos are designed to store fly ash, a byproduct of coal combustion used as a supplementary cementitious material. Both systems improve material handling efficiency and protect contents from moisture and contamination, but fly ash silos must accommodate finer, lighter particles requiring specialized sealing and dust control. Your choice depends on the specific material properties and storage requirements critical to maintaining quality and process reliability.

Material Storage: Cement vs. Fly Ash

Cement bins are designed to store powdered cement with features that prevent moisture ingress and maintain material flowability, using airtight seals and vibration systems to avoid clumping. Fly ash silos, in contrast, address the finer particles and lower density of fly ash by incorporating pneumatic systems and specialized aeration to ensure consistent discharge and prevent segregation. Both storage systems emphasize corrosion-resistant materials and dust control measures, but the handling requirements differ significantly due to the distinct physical and chemical properties of cement versus fly ash.

Design Differences Between Cement Bins and Fly Ash Silos

Cement bins typically feature robust steel construction with airtight seals to prevent moisture ingress, ensuring cement quality is maintained, while fly ash silos are designed with specialized venting systems to handle fine particulate matter and reduce dust emissions. The design of cement bins prioritizes pressure resistance for bulk cement storage, whereas fly ash silos incorporate multiple discharge outlets and dust collectors for efficient material flow and environmental compliance. Your choice between the two should consider these structural and functional differences to optimize storage performance.

Capacity and Volume Comparison

Cement bins generally have smaller capacities, typically ranging from 5 to 50 tons, while fly ash silos can hold significantly larger volumes, often between 50 to 200 tons or more, making them suitable for bulk storage. The design of fly ash silos accommodates the lighter, finer material, enabling higher volume storage without compromising structural integrity. Understanding these capacity differences helps you select the appropriate storage solution for your construction material needs.

Material Handling and Discharge Systems

Cement bins are designed to store and discharge high-density, fine cement powder using gravity or mechanical screw conveyors for precise metering in concrete production. Fly ash silos, built to handle lightweight, powdery byproducts from coal combustion, typically employ pneumatic or air-assisted discharge systems to prevent material compaction and ensure smooth flow. Both systems incorporate features like vibrators and aeration pads to optimize material flow, addressing the specific handling characteristics of each stored material.

Construction Materials and Longevity

Cement bins are typically constructed using heavy-duty steel or reinforced concrete to withstand the abrasive nature of cement particles, ensuring durability and long-term performance in harsh environments. Fly ash silos also employ robust materials like carbon steel with corrosion-resistant coatings to handle the fine, powdery texture of fly ash and prevent material degradation over time. Both storage solutions prioritize structural integrity and protection against moisture to maximize lifespan and maintain the quality of construction materials.

Cost Analysis: Cement Bin vs. Fly Ash Silo

Cement bins generally incur lower initial costs compared to fly ash silos due to simpler design and material requirements. Fly ash silos demand higher investment for specialized coatings and airtight sealing to prevent dust emissions and moisture infiltration. Your choice should consider long-term operational expenses, maintenance frequency, and material handling needs that may impact overall cost-effectiveness between the two storage options.

Installation and Maintenance Requirements

Cement bins require sturdy foundations and precise alignment during installation to handle heavy loads and prevent structural damage, while fly ash silos demand specialized sealing systems to manage fine particulate containment and minimize dust leakage. Maintenance of cement bins involves regular inspection for corrosion, wear, and structural integrity, with emphasis on hopper outlets and discharge systems, whereas fly ash silos need frequent cleaning of filters and monitoring of pressure relief valves to ensure optimal airflow and prevent blockages. Your choice depends on the emphasis placed on ease of installation versus ongoing maintenance complexity in managing powder storage facilities.

Environmental Impact Considerations

Cement bins typically contribute higher carbon emissions due to the energy-intensive production and transportation processes of cement, while fly ash silos promote sustainability by enabling the use of fly ash, a byproduct of coal combustion, as a supplementary cementitious material that reduces landfill waste and lowers overall carbon footprint. Using fly ash in concrete mixtures decreases the demand for Portland cement, significantly cutting greenhouse gas emissions associated with cement manufacturing. Proper storage in fly ash silos prevents dust pollution and minimizes environmental hazards compared to the dustier handling of cement in traditional bins.

Choosing the Right Solution for Your Project

Selecting between a cement bin and a fly ash silo depends on project requirements, material compatibility, and storage capacity. Cement bins are designed for dense, dry cement powder with features to prevent moisture and maintain material quality, while fly ash silos accommodate lighter, fine ash powder with specialized aeration systems for flow efficiency. Evaluating factors such as project scale, material handling needs, and environmental conditions ensures optimal storage, cost-efficiency, and operational performance.

Cement bin vs Fly ash silo Infographic

libmatt.com

libmatt.com