Alkali content in materials affects chemical reactivity and combustion processes, while sulfur content primarily influences environmental emissions and corrosion potential. Monitoring both alkali and sulfur content is essential to optimize performance and reduce harmful impacts in industrial applications.

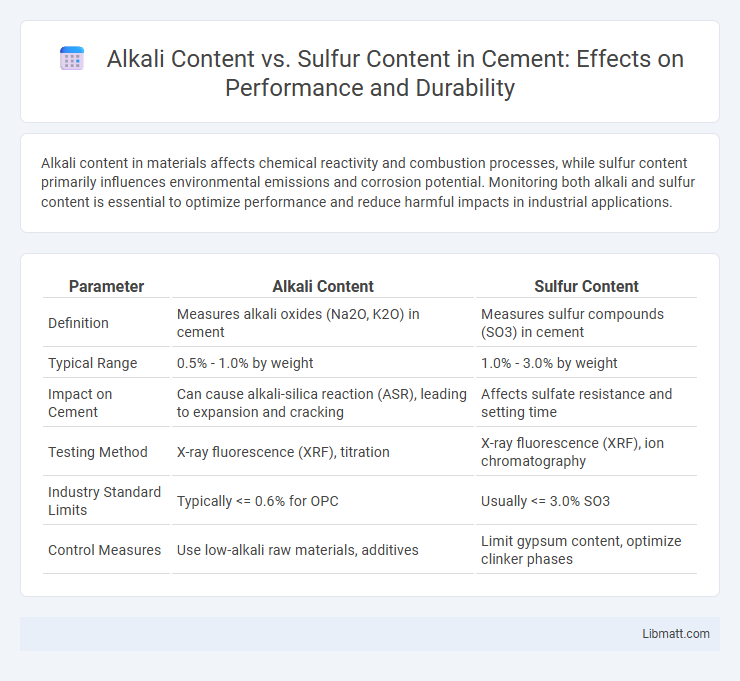

Table of Comparison

| Parameter | Alkali Content | Sulfur Content |

|---|---|---|

| Definition | Measures alkali oxides (Na2O, K2O) in cement | Measures sulfur compounds (SO3) in cement |

| Typical Range | 0.5% - 1.0% by weight | 1.0% - 3.0% by weight |

| Impact on Cement | Can cause alkali-silica reaction (ASR), leading to expansion and cracking | Affects sulfate resistance and setting time |

| Testing Method | X-ray fluorescence (XRF), titration | X-ray fluorescence (XRF), ion chromatography |

| Industry Standard Limits | Typically <= 0.6% for OPC | Usually <= 3.0% SO3 |

| Control Measures | Use low-alkali raw materials, additives | Limit gypsum content, optimize clinker phases |

Introduction to Alkali and Sulfur Content

Alkali content and sulfur content are critical parameters in fuel and coal analysis that significantly impact combustion processes and environmental emissions. Alkali metals, such as sodium and potassium, can cause fouling and corrosion in boilers, while sulfur content primarily contributes to sulfur dioxide (SO2) emissions, leading to acid rain and air pollution. Accurate measurement of both alkali and sulfur content ensures optimized fuel performance and compliance with environmental regulations.

Chemical Properties of Alkali Elements

Alkali elements, including lithium, sodium, and potassium, are characterized by their single valence electron, which results in high reactivity and strong basicity in chemical compounds. These metals readily form alkaline hydroxides that significantly influence the alkali content in substances, affecting processes like combustion and mineral formation. The reaction between alkali metals and sulfur compounds determines the sulfur content by forming sulfides, impacting corrosion resistance and environmental emissions in industrial applications.

Sulfur Content: Definitions and Importance

Sulfur content refers to the amount of sulfur present in a material, commonly measured in fuels, coal, or soil, and it significantly affects environmental emissions and material quality. High sulfur content leads to increased sulfur dioxide (SO2) emissions during combustion, contributing to acid rain and air pollution, making its regulation crucial for environmental compliance. Monitoring your sulfur content ensures adherence to industry standards and protects both equipment longevity and ecological health.

Sources of Alkali and Sulfur in Materials

Alkali content in materials primarily originates from minerals such as feldspars, micas, and clays, with sodium and potassium being the most common alkali elements. Sulfur content is mainly derived from sulfide minerals like pyrite (FeS2), gypsum (CaSO4*2H2O), and organic sulfur compounds present in fossil fuels and sedimentary rocks. Understanding these sources is crucial for managing material properties in industrial processes like cement production and combustion.

Effects of Alkali Content on Material Performance

Alkali content in materials significantly influences their durability and strength, particularly in cement and concrete applications where high alkali levels can lead to alkali-silica reaction (ASR), causing cracking and structural damage. Controlling alkali content helps optimize material performance by reducing susceptibility to chemical degradation and enhancing long-term stability. Understanding your material's alkali content is crucial for ensuring resistance to environmental stressors and maintaining overall integrity.

Influence of Sulfur Content on Durability

Elevated sulfur content in materials significantly impacts durability by accelerating degradation processes such as corrosion and sulfate attack in concrete structures. High sulfur levels promote the formation of expansive sulfates, which cause cracking and loss of mechanical integrity over time. Controlling sulfur content alongside alkali levels is essential for enhancing the longevity and structural stability of engineered materials.

Alkali-Sulfur Interactions in Industrial Processes

Alkali content significantly influences sulfur behavior in industrial processes by promoting the formation of alkali sulfates, which affect corrosion rates and fouling tendencies in boilers and gas turbines. High alkali levels enhance sulfur retention in solid residues, altering emission profiles and impacting the efficiency of sulfur capture technologies such as flue gas desulfurization (FGD). Understanding the interaction between alkali metals (e.g., sodium, potassium) and sulfur compounds is critical for optimizing combustion conditions and minimizing operational issues in power generation and chemical manufacturing industries.

Analytical Methods for Measuring Alkali and Sulfur

Analytical methods for measuring alkali content commonly include inductively coupled plasma optical emission spectrometry (ICP-OES) and atomic absorption spectroscopy (AAS), which provide precise quantification of elements like sodium and potassium. Sulfur content is frequently determined using techniques such as X-ray fluorescence (XRF) and combustion analysis with infrared detection, ensuring accurate sulfur quantification in diverse samples. Your choice of method depends on sample type and required sensitivity, optimizing accuracy in alkali and sulfur content analysis.

Impacts on Environment and Compliance Standards

High alkali content in fuels contributes to the formation of particulate matter and alkaline aerosols, which can harm respiratory health and ecosystems. Elevated sulfur content leads to sulfur dioxide (SO2) emissions, causing acid rain, soil acidification, and water pollution, severely impacting biodiversity and human health. Regulatory frameworks such as the Clean Air Act and Euro VI standards limit alkali and sulfur levels in fuels to ensure environmental protection and compliance with air quality standards.

Strategies for Controlling Alkali and Sulfur Levels

Effective strategies for controlling alkali and sulfur levels in industrial processes include the use of high-efficiency scrubbers and tailored additives that capture or neutralize these compounds. Selecting low-alkali and low-sulfur raw materials alongside optimized combustion techniques reduces their formation and emission. Continuous monitoring with advanced sensors ensures precise adjustment, maintaining compliance with environmental regulations and enhancing process efficiency.

Alkali Content vs Sulfur Content Infographic

libmatt.com

libmatt.com