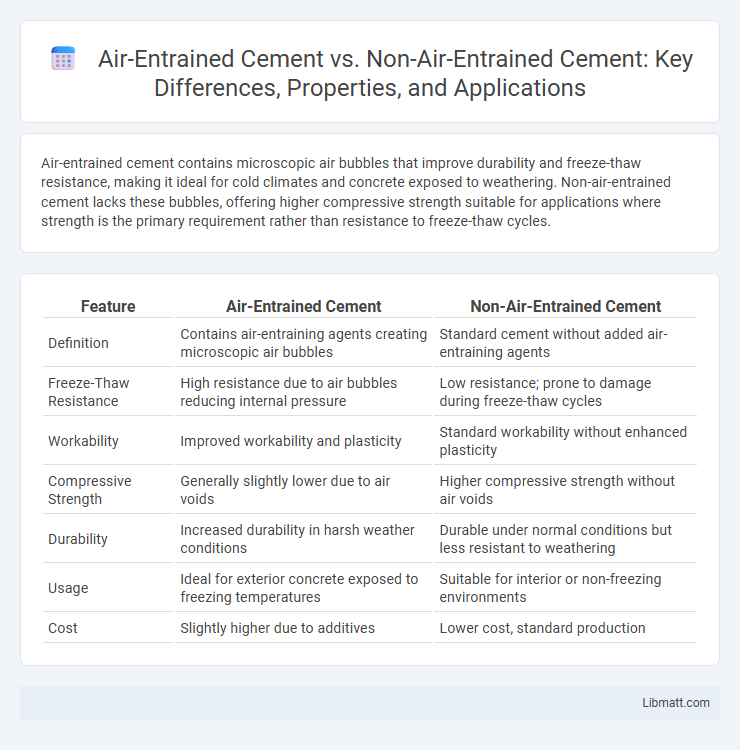

Air-entrained cement contains microscopic air bubbles that improve durability and freeze-thaw resistance, making it ideal for cold climates and concrete exposed to weathering. Non-air-entrained cement lacks these bubbles, offering higher compressive strength suitable for applications where strength is the primary requirement rather than resistance to freeze-thaw cycles.

Table of Comparison

| Feature | Air-Entrained Cement | Non-Air-Entrained Cement |

|---|---|---|

| Definition | Contains air-entraining agents creating microscopic air bubbles | Standard cement without added air-entraining agents |

| Freeze-Thaw Resistance | High resistance due to air bubbles reducing internal pressure | Low resistance; prone to damage during freeze-thaw cycles |

| Workability | Improved workability and plasticity | Standard workability without enhanced plasticity |

| Compressive Strength | Generally slightly lower due to air voids | Higher compressive strength without air voids |

| Durability | Increased durability in harsh weather conditions | Durable under normal conditions but less resistant to weathering |

| Usage | Ideal for exterior concrete exposed to freezing temperatures | Suitable for interior or non-freezing environments |

| Cost | Slightly higher due to additives | Lower cost, standard production |

Introduction to Air-Entrained vs Non-Air-Entrained Cement

Air-entrained cement contains microscopic air bubbles that improve durability and resistance to freeze-thaw cycles compared to non-air-entrained cement, which lacks these entrained air pockets. The inclusion of air improves workability and reduces the risk of cracking in cold climates, making air-entrained cement ideal for outdoor concrete applications. When selecting your cement type, consider environmental exposure and performance requirements to ensure long-lasting structural integrity.

Composition Differences Between Air-Entrained and Non-Air-Entrained Cement

Air-entrained cement contains tiny, uniformly distributed air bubbles created by adding air-entraining agents such as synthetic detergents or wood resins, which increase durability and resistance to freeze-thaw cycles. Non-air-entrained cement lacks these intentional air voids, resulting in a denser composition with higher compressive strength but reduced resistance to freeze-thaw damage. The key compositional difference lies in the inclusion of air-entraining admixtures that modify the microstructure, impacting performance characteristics in cold environments.

Manufacturing Process of Air-Entrained Cement

The manufacturing process of air-entrained cement involves incorporating air-entraining agents such as synthetic detergents or natural surfactants during the grinding stage of cement production, creating microscopic air bubbles. These air bubbles improve the cement's freeze-thaw resistance and workability by increasing its durability and reducing permeability. By understanding this process, you can select air-entrained cement for applications requiring enhanced resistance to weathering and cracking.

Key Properties of Air-Entrained Cement

Air-entrained cement incorporates microscopic air bubbles that enhance freeze-thaw durability and resistance to scaling in concrete exposed to harsh weather conditions. These air voids improve workability by increasing plasticity and reducing bleeding, making the mix easier to handle. Your choice of air-entrained cement can significantly extend the lifespan of structures subjected to cyclic freezing and thawing.

Key Properties of Non-Air-Entrained Cement

Non-air-entrained cement exhibits higher density and compressive strength due to its lack of entrapped air voids, making it suitable for structural applications requiring maximum load-bearing capacity. This type of cement offers superior durability in environments where freeze-thaw resistance is not critical, as it lacks the microbubbles that improve resistance to cyclic freezing. The low permeability and dense microstructure of non-air-entrained cement enhance its performance in aggressive chemical exposures, ensuring long-term stability in standard concrete mixes.

Workability and Ease of Placement

Air-entrained cement significantly improves workability by incorporating microscopic air bubbles that reduce water demand and increase the mixture's cohesion, making placement easier in complex forms and tight spaces. Non-air-entrained cement typically requires more water and admixtures to achieve comparable workability, potentially leading to segregation or bleeding during placement. The presence of air voids in air-entrained cement enhances the ease of handling and finishing concrete, especially in cold weather conditions where freeze-thaw durability is critical.

Durability and Resistance to Freeze-Thaw Cycles

Air-entrained cement contains microscopic air bubbles that significantly enhance durability by improving resistance to freeze-thaw cycles, reducing internal stress caused by water expansion during freezing. Non-air-entrained cement lacks these air voids, making it more susceptible to cracking and scaling in cold climates. The entrained air improves longevity in concrete exposed to moisture and temperature fluctuations by allowing space for ice formation without compromising structural integrity.

Applications and Best Use Cases

Air-entrained cement is ideal for applications exposed to freeze-thaw cycles, such as sidewalks, bridges, and pavements, because the microscopic air bubbles enhance durability by reducing internal stress. Non-air-entrained cement suits interior construction and environments without moisture variation, where strength and smooth finishes are prioritized over freeze-thaw resistance. Your choice should align with environmental conditions and structural requirements to optimize performance and longevity.

Limitations and Drawbacks of Each Type

Air-entrained cement improves freeze-thaw durability by incorporating microscopic air bubbles, but its reduced compressive strength limits its use in structural applications requiring high load-bearing capacity. Non-air-entrained cement provides higher strength but lacks resistance to freeze-thaw cycles, making it prone to cracking and scaling in cold climates. Your choice should balance durability needs against mechanical performance to prevent premature deterioration or failure.

Choosing the Right Cement for Your Project

Air-entrained cement contains microscopic air bubbles that improve freeze-thaw durability and resistance to scaling, making it ideal for outdoor or cold climate projects. Non-air-entrained cement offers higher compressive strength and is suitable for interior applications or environments not exposed to harsh weather. Choosing the right cement for your project depends on environmental conditions and specific performance requirements to ensure longevity and structural integrity.

Air-Entrained Cement vs Non-Air-Entrained Cement Infographic

libmatt.com

libmatt.com