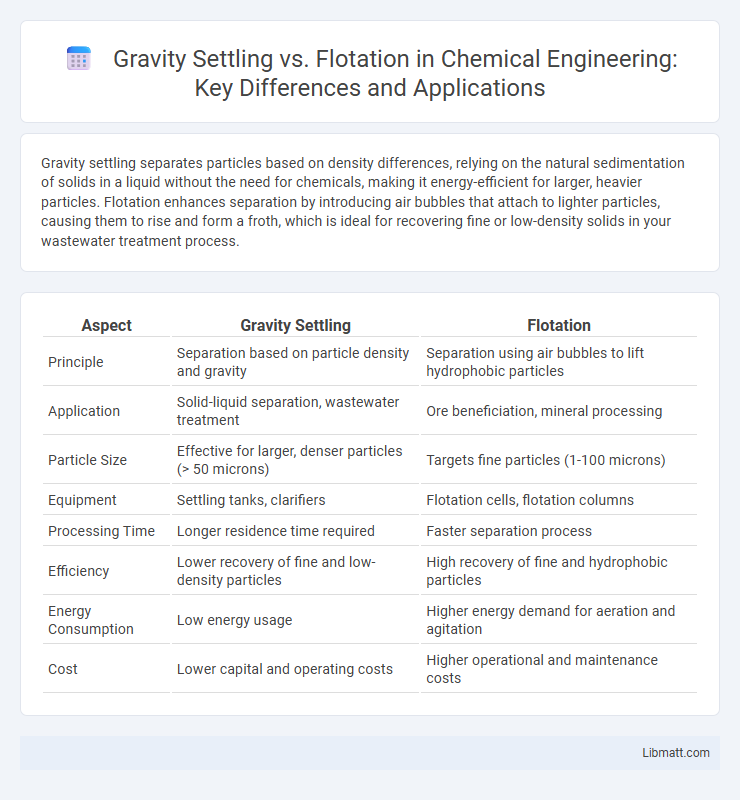

Gravity settling separates particles based on density differences, relying on the natural sedimentation of solids in a liquid without the need for chemicals, making it energy-efficient for larger, heavier particles. Flotation enhances separation by introducing air bubbles that attach to lighter particles, causing them to rise and form a froth, which is ideal for recovering fine or low-density solids in your wastewater treatment process.

Table of Comparison

| Aspect | Gravity Settling | Flotation |

|---|---|---|

| Principle | Separation based on particle density and gravity | Separation using air bubbles to lift hydrophobic particles |

| Application | Solid-liquid separation, wastewater treatment | Ore beneficiation, mineral processing |

| Particle Size | Effective for larger, denser particles (> 50 microns) | Targets fine particles (1-100 microns) |

| Equipment | Settling tanks, clarifiers | Flotation cells, flotation columns |

| Processing Time | Longer residence time required | Faster separation process |

| Efficiency | Lower recovery of fine and low-density particles | High recovery of fine and hydrophobic particles |

| Energy Consumption | Low energy usage | Higher energy demand for aeration and agitation |

| Cost | Lower capital and operating costs | Higher operational and maintenance costs |

Introduction to Gravity Settling and Flotation

Gravity settling separates suspended solids from liquids by allowing particles to settle naturally due to density differences and gravitational force, making it effective for removing heavier solids in wastewater treatment. Flotation enhances separation by introducing fine gas bubbles that attach to lighter particles, causing them to rise to the surface for removal, commonly used in mineral processing and oil-water separation. Both methods leverage different physical principles to achieve efficient solid-liquid separation based on particle density and size.

Basic Principles of Gravity Settling

Gravity settling relies on the natural force of gravity to separate suspended particles from a liquid by allowing heavier solids to settle at the bottom over time. This process is governed by Stokes' Law, which predicts the settling velocity of particles based on their size, shape, and density as well as the viscosity of the fluid. Gravity settling is energy-efficient and commonly used in water and wastewater treatment for the removal of suspended solids before further processing.

Fundamental Concepts of Flotation

Flotation involves separating particles based on their hydrophobic properties, where air bubbles selectively attach to hydrophobic particles and lift them to the surface for collection. This process relies on surface chemistry and physicochemical interactions, achieving separation that gravity settling cannot by targeting fine and low-density particles. Understanding the fundamental concepts of flotation allows you to optimize the efficiency of solid-liquid separation in mineral processing or wastewater treatment.

Key Differences Between Gravity Settling and Flotation

Gravity settling relies on the natural force of gravity to separate particles from liquids based on density differences, making it effective for larger, heavier solids. Flotation uses air bubbles to attach to lighter, hydrophobic particles, lifting them to the surface for removal, ideal for fine particles and oils. Your choice between these methods depends on the particle size, density, and the specific contaminants present in the liquid.

Applications of Gravity Settling in Industry

Gravity settling is widely applied in wastewater treatment plants for separating suspended solids from liquids, enhancing water clarity and quality. It plays a crucial role in mining operations for mineral sand separation, where denser particles settle under gravity. In the food and beverage industry, gravity settling helps clarify liquids such as juices and wines by removing sediments without chemical additives.

Applications of Flotation in Industry

Flotation is widely applied in mineral processing industries to separate valuable minerals from ores, with significant use in the extraction of copper, lead, zinc, and coal. It enhances the concentration of fine particles by attaching hydrophobic materials to air bubbles, which rise to the surface and form froth for removal, making it effective for low-grade and complex ores. Industrial applications also extend to wastewater treatment, where flotation removes oil, grease, and suspended solids, improving effluent quality and meeting environmental regulations.

Advantages of Gravity Settling

Gravity settling offers advantages such as low energy consumption and simple operational requirements, making it cost-effective for separating suspended solids from liquids. It effectively handles large volumes of wastewater with minimal maintenance, ensuring reliable removal of heavy particles. Your treatment process benefits from its environmentally friendly approach due to the absence of chemical additives and reduced sludge production.

Benefits of Flotation Processes

Flotation processes offer significant benefits over gravity settling, including higher efficiency in separating fine particles and minerals from slurry due to air bubble attachment mechanisms. This method enhances recovery rates of valuable ores, particularly sulfide minerals, by selectively separating hydrophobic materials. Flotation also reduces water consumption and improves concentrate grade, making it a preferred technique in mineral processing industries.

Limitations and Challenges of Each Method

Gravity settling faces limitations in handling fine or low-density particles due to slow settling rates and requires large space for effective separation. Flotation struggles with high concentrations of solids and can be sensitive to changes in water chemistry, affecting bubble-particle attachment efficiency. Your choice between these methods depends on specific wastewater characteristics and operational constraints.

Choosing the Right Separation Technique

Selecting the appropriate separation technique between gravity settling and flotation depends on particle size, density, and surface properties of the materials involved. Gravity settling excels in separating heavier and larger particles by exploiting density differences, while flotation targets fine particles by using surface chemistry to attach particles to air bubbles. Understanding feed characteristics and process requirements ensures optimal recovery and efficiency in mineral processing or wastewater treatment applications.

Gravity settling vs flotation Infographic

libmatt.com

libmatt.com