A spouted bed features a narrow gas inlet that creates a high-velocity jet, causing particles to circulate in a spout-like motion ideal for handling coarse or irregular particles, while a fluidized bed distributes gas uniformly through a perforated plate to suspend particles evenly, promoting excellent mixing and heat transfer. Your choice depends on the particle size, desired mixing efficiency, and process application, where spouted beds excel in drying and coating coarse materials, and fluidized beds are preferred for catalytic reactions and combustion.

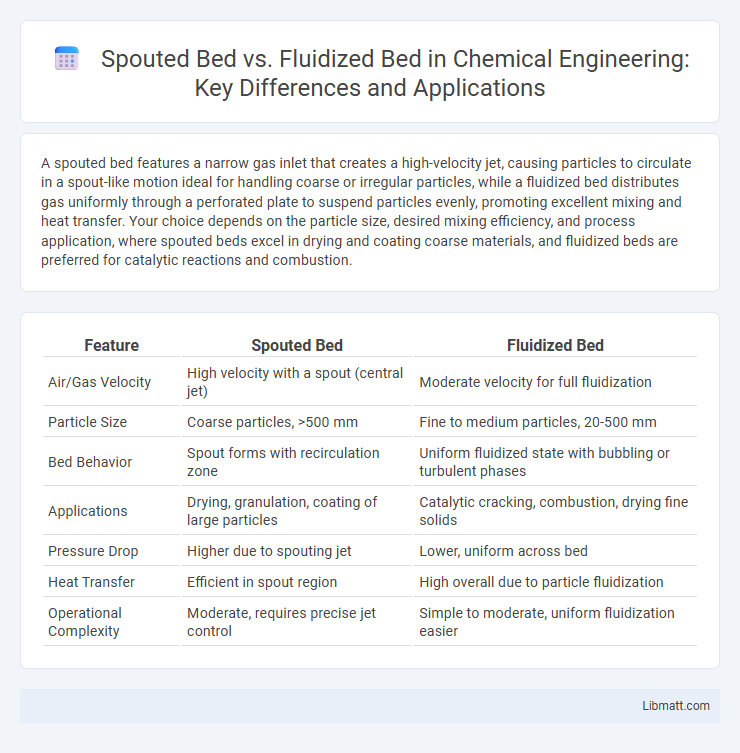

Table of Comparison

| Feature | Spouted Bed | Fluidized Bed |

|---|---|---|

| Air/Gas Velocity | High velocity with a spout (central jet) | Moderate velocity for full fluidization |

| Particle Size | Coarse particles, >500 mm | Fine to medium particles, 20-500 mm |

| Bed Behavior | Spout forms with recirculation zone | Uniform fluidized state with bubbling or turbulent phases |

| Applications | Drying, granulation, coating of large particles | Catalytic cracking, combustion, drying fine solids |

| Pressure Drop | Higher due to spouting jet | Lower, uniform across bed |

| Heat Transfer | Efficient in spout region | High overall due to particle fluidization |

| Operational Complexity | Moderate, requires precise jet control | Simple to moderate, uniform fluidization easier |

Introduction to Spouted Bed and Fluidized Bed Technologies

Spouted bed and fluidized bed technologies are advanced methods used for processing granular materials through gas-solid interactions. A spouted bed utilizes a high-velocity jet of gas to create a spout, promoting intense particle circulation within a conical vessel, ideal for processes requiring effective mixing and heat transfer. Fluidized beds suspend solid particles in an upward-flowing fluid, creating a fluid-like behavior that enhances reaction rates and uniform temperature distribution, making it suitable for combustion, drying, and catalytic reactions in your industrial applications.

Fundamental Working Principles

Spouted beds operate by introducing gas through a localized nozzle, creating a high-velocity gas jet that causes particles to circulate in a conical pattern, enhancing particle movement and heat transfer. Fluidized beds uniformly distribute gas through a perforated plate, suspending solid particles in a fluid-like state that promotes excellent mixing and reaction rates. Both systems leverage gas-solid interactions but differ in gas flow patterns and particle dynamics, impacting their suitability for various industrial processes.

Design and Construction Differences

Spouted beds feature a conical base that channels a high-velocity gas jet through a single central nozzle, creating a vigorous, cyclic particle movement ideal for coarse or irregular particles. Fluidized beds use a distributor plate to evenly disperse gas through a perforated base, suspending and fluidizing particles uniformly for consistent heat and mass transfer. Design complexity in spouted beds centers on nozzle geometry and gas velocity control, while fluidized beds require precise distributor plate design and bed height management to maintain uniform fluidization.

Particle Movement and Dynamics

Spouted beds feature a localized jet of air that propels particles upward in a cyclic motion, creating a spiraling particle movement that enhances mixing and heat transfer. Fluidized beds maintain particles in a suspended state by uniformly distributing gas flow, resulting in random particle collisions and consistent turbulence throughout the bed. Particle dynamics in spouted beds exhibit a more defined circulation pattern, whereas fluidized beds show homogenous suspension and fluid-like behavior of solid particles.

Applications and Industrial Uses

Spouted beds excel in handling coarse, irregular particles and are widely used in drying processes, coating, and granulation within the pharmaceutical and food industries. Fluidized beds provide efficient heat and mass transfer, making them ideal for catalytic reactions, combustion, and drying in petrochemical, chemical, and mineral processing sectors. Your choice depends on particle characteristics and process requirements, with fluidized beds favored for fine particles and complex reactions, while spouted beds suit larger, dense materials.

Energy Efficiency Comparison

Spouted beds generally offer higher energy efficiency than fluidized beds due to more targeted particle movement and reduced mixing, which lowers power consumption. Fluidized beds require continuous gas flow to maintain particle suspension, often leading to greater energy use for aeration and circulation. Optimizing your process with a spouted bed can result in significant energy savings, particularly in applications involving coarse or irregular particles.

Advantages of Spouted Beds

Spouted beds offer superior handling of coarse and irregularly shaped particles compared to fluidized beds, ensuring efficient circulation and minimizing channeling or dead zones. They require lower gas velocity, resulting in reduced energy consumption while maintaining effective mixing and heat transfer for your processing needs. The robust design of spouted beds also allows for easier scale-up and better control over particle residence time.

Benefits of Fluidized Beds

Fluidized beds provide superior heat and mass transfer rates, enhancing reaction efficiency in processes like combustion, drying, and catalytic reactions. They maintain excellent temperature uniformity and prevent hot spots, reducing the risk of thermal degradation and improving product quality. The scalability and operational flexibility of fluidized beds make them ideal for handling a wide range of particle sizes and feedstocks with reduced equipment wear.

Key Challenges and Limitations

Spouted beds face challenges such as limited scalability and difficulty in maintaining a stable spout, leading to uneven particle circulation and potential clogging issues. Fluidized beds encounter limitations including particle attrition, channeling, and entrainment, which can reduce efficiency and affect uniform temperature distribution. Both technologies require careful control of operating parameters to mitigate these issues and ensure optimal performance in industrial applications.

Choosing the Right Bed for Your Process

Spouted beds offer concentrated jetting of gas that creates a central, high-velocity spout ideal for processing large particles and dense materials, ensuring efficient circulation and mixing. In contrast, fluidized beds provide uniform particle suspension and excellent heat transfer, making them suitable for fine particles and uniform fluid dynamics. Selecting between spouted and fluidized beds depends on particle size, density, heat transfer needs, and process uniformity requirements to optimize performance and energy efficiency.

Spouted bed vs fluidized bed Infographic

libmatt.com

libmatt.com