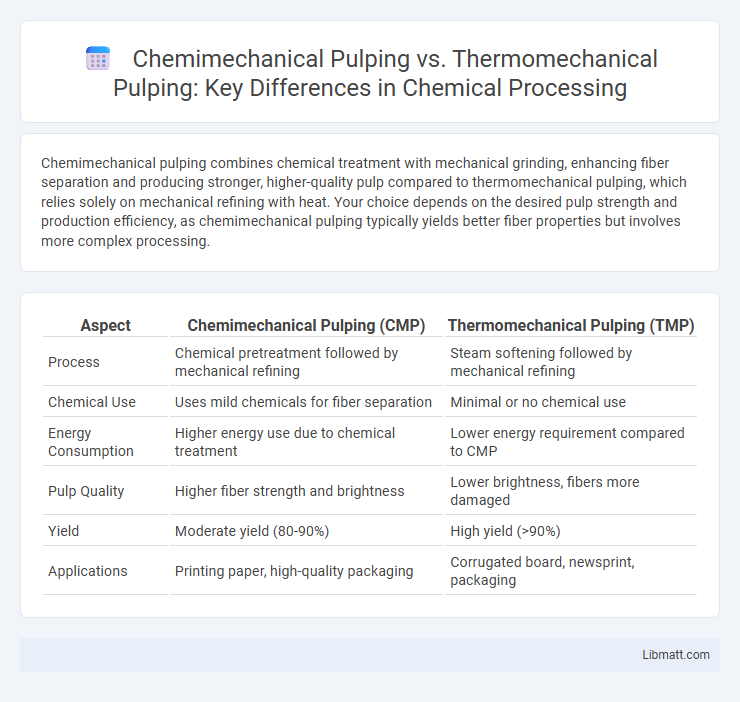

Chemimechanical pulping combines chemical treatment with mechanical grinding, enhancing fiber separation and producing stronger, higher-quality pulp compared to thermomechanical pulping, which relies solely on mechanical refining with heat. Your choice depends on the desired pulp strength and production efficiency, as chemimechanical pulping typically yields better fiber properties but involves more complex processing.

Table of Comparison

| Aspect | Chemimechanical Pulping (CMP) | Thermomechanical Pulping (TMP) |

|---|---|---|

| Process | Chemical pretreatment followed by mechanical refining | Steam softening followed by mechanical refining |

| Chemical Use | Uses mild chemicals for fiber separation | Minimal or no chemical use |

| Energy Consumption | Higher energy use due to chemical treatment | Lower energy requirement compared to CMP |

| Pulp Quality | Higher fiber strength and brightness | Lower brightness, fibers more damaged |

| Yield | Moderate yield (80-90%) | High yield (>90%) |

| Applications | Printing paper, high-quality packaging | Corrugated board, newsprint, packaging |

Introduction to Mechanical Pulping Processes

Mechanical pulping processes transform wood chips into pulp by physically separating fibers while retaining most lignin, resulting in high yield and good bulk. Chemimechanical pulping uses chemicals, typically sodium sulfite, to soften lignin before mechanical refining, enhancing fiber separation and improving strength. Thermomechanical pulping relies on heat and mechanical refining without chemical treatment, yielding pulp with higher brightness but lower strength compared to chemimechanical methods.

Overview of Chemimechanical Pulping (CMP)

Chemimechanical pulping (CMP) combines chemical treatment with mechanical refining to separate fibers while preserving their strength and brightness. This method uses mild chemical softening agents, such as sodium sulfite, reducing energy consumption and enhancing pulp quality compared to traditional mechanical pulping. Your choice of CMP can result in improved fiber bonding and reduced lignin content, optimizing paper durability and printability.

Overview of Thermomechanical Pulping (TMP)

Thermomechanical pulping (TMP) is a mechanical process that uses heat and mechanical refining to separate wood fibers, producing pulp with high fiber yield and strength suitable for printing and writing papers. Unlike chemimechanical pulping, TMP softens wood chips using steam before refining, minimizing fiber damage and maintaining brightness without extensive chemical treatment. Your choice of TMP can enhance pulp quality by balancing fiber integrity and production efficiency, ideal for applications requiring strong, high-quality paper.

Key Differences Between CMP and TMP

Chemimechanical pulping (CMP) uses chemical pretreatment to soften wood chips before mechanical refining, resulting in higher fiber strength and lower energy consumption compared to thermomechanical pulping (TMP), which relies solely on mechanical refining with heat and pressure. CMP produces pulp with improved fiber bonding and reduced lignin content, enhancing paper quality, while TMP yields higher yields but with more lignin retained, affecting brightness and aging properties. Your choice between CMP and TMP impacts production efficiency, energy use, and the final paper characteristics, emphasizing the balance between quality and cost.

Raw Material Requirements

Chemimechanical pulping (CMP) requires wood chips with moderate lignin content, as chemical pretreatment softens fibers and reduces energy consumption during refining. Thermomechanical pulping (TMP) relies on fresh wood with low moisture content and uniform wood species to withstand high temperatures and mechanical shear without excessive fiber damage. Both processes demand carefully selected raw materials to optimize pulp yield, strength, and energy efficiency in paper manufacturing.

Chemical Usage and Environmental Impact

Chemimechanical pulping (CMP) uses chemicals such as sodium bisulfite to soften wood fibers, resulting in lower energy consumption compared to thermomechanical pulping (TMP), which primarily relies on heat and mechanical refining without chemical additives. CMP produces less mechanical damage to fibers, improving pulp quality while also generating effluents with higher chemical oxygen demand (COD) due to chemical usage, posing challenges for wastewater treatment. Your choice between CMP and TMP affects environmental impact through chemical discharge levels and energy efficiency, making CMP more sensitive to chemical management and TMP more energy-intensive.

Energy Consumption and Efficiency

Chemimechanical pulping generally consumes less energy than thermomechanical pulping due to the chemical pretreatment that softens the wood fibers, reducing the mechanical refining intensity required. Thermomechanical pulping demands higher energy input, primarily electricity, as it relies on mechanical grinding at elevated temperatures to separate fibers. The energy efficiency of chemimechanical pulping enhances yield and fiber quality, making it more economical and environmentally favorable for certain wood types.

Pulp Quality and Paper Properties

Chemimechanical pulping produces pulp with higher brightness and better fiber strength compared to thermomechanical pulping, resulting in improved paper quality suitable for printing and writing papers. Thermomechanical pulping typically yields pulp with higher yields but contains more fines and lignin, leading to paper with lower brightness and physical durability. Your choice between these methods depends on prioritizing either pulp strength and brightness or process efficiency and yield.

Industrial Applications and End-Uses

Chemimechanical pulping (CMP) is widely used in producing high-quality printing and writing papers due to its balance of strength and brightness, making it ideal for fine paper applications. Thermomechanical pulping (TMP) is preferred for packaging materials and newsprint, offering higher yield and bulk but with lower brightness and strength compared to CMP. Industries prioritize CMP for specialty paper products requiring superior surface properties, whereas TMP is favored in cost-sensitive mass paper production with moderate strength demands.

Future Trends in Mechanical Pulping Technologies

Future trends in mechanical pulping technologies emphasize improving energy efficiency and enhancing fiber quality through innovative chemimechanical pulping (CMP) methods that reduce chemical consumption compared to traditional thermomechanical pulping (TMP). Advances in enzyme-assisted pulping and resin extraction techniques aim to increase pulp strength and brightness while lowering environmental impact. Your mill can benefit from these developments by adopting hybrid processes that optimize resource use and produce higher-value pulp products suitable for sustainable packaging and printing applications.

Chemimechanical pulping vs thermomechanical pulping Infographic

libmatt.com

libmatt.com