Crosslinked polymers exhibit a three-dimensional network structure that provides superior mechanical strength, thermal stability, and chemical resistance compared to linear polymers, which consist of individual chains with weaker intermolecular forces. Your choice between crosslinked and linear polymers should depend on the desired application properties, such as flexibility or rigidity, durability, and environmental exposure.

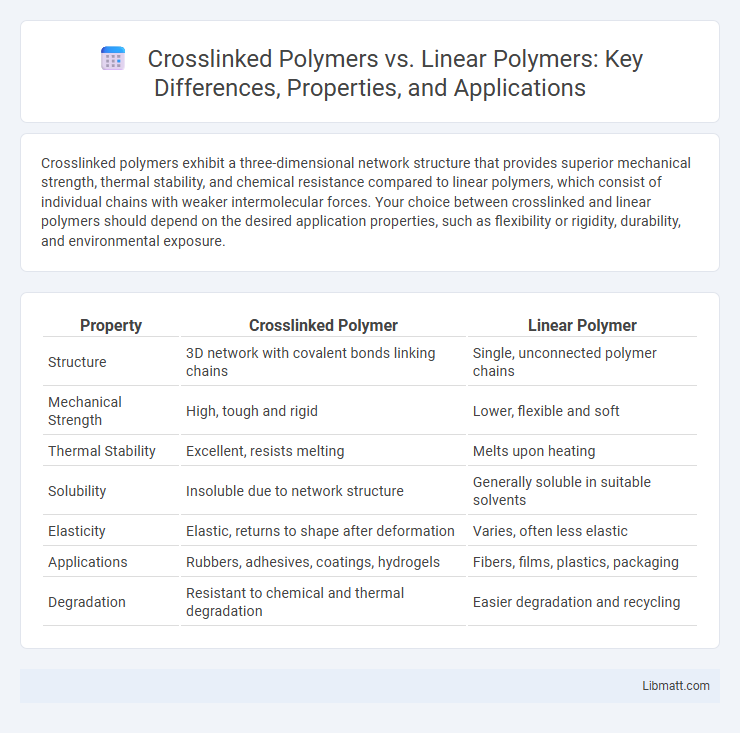

Table of Comparison

| Property | Crosslinked Polymer | Linear Polymer |

|---|---|---|

| Structure | 3D network with covalent bonds linking chains | Single, unconnected polymer chains |

| Mechanical Strength | High, tough and rigid | Lower, flexible and soft |

| Thermal Stability | Excellent, resists melting | Melts upon heating |

| Solubility | Insoluble due to network structure | Generally soluble in suitable solvents |

| Elasticity | Elastic, returns to shape after deformation | Varies, often less elastic |

| Applications | Rubbers, adhesives, coatings, hydrogels | Fibers, films, plastics, packaging |

| Degradation | Resistant to chemical and thermal degradation | Easier degradation and recycling |

Introduction to Polymer Structures

Crosslinked polymers consist of polymer chains interconnected through covalent bonds, creating a three-dimensional network that enhances mechanical strength and thermal stability compared to linear polymers. Linear polymers feature long, unbranched chains that allow for greater flexibility and easier processability but generally exhibit lower resistance to heat and solvents. Understanding these fundamental differences in polymer structures helps you select the appropriate material for applications requiring durability or flexibility.

What Are Linear Polymers?

Linear polymers consist of long, continuous chains of repeating monomer units connected end-to-end without branching or crosslinking, resulting in flexible and often crystalline materials. These polymers, such as polyethylene and polyvinyl chloride (PVC), exhibit thermoplastic properties, allowing them to soften upon heating and be reshaped. Their molecular arrangement leads to distinct mechanical characteristics like tensile strength and ductility, differentiating them from crosslinked polymers that possess three-dimensional networks.

What Are Crosslinked Polymers?

Crosslinked polymers consist of polymer chains linked together by covalent bonds, forming a three-dimensional network structure that enhances mechanical strength and thermal stability compared to linear polymers. These crosslinks restrict chain mobility, resulting in improved resistance to solvents, deformation, and high temperatures. Common examples include vulcanized rubber and epoxy resins, widely used in applications requiring durable, rigid materials.

Molecular Architecture: Linear vs Crosslinked

Crosslinked polymers consist of molecular chains interconnected by covalent bonds, forming a three-dimensional network that enhances mechanical strength, thermal stability, and chemical resistance compared to linear polymers. Linear polymers feature single, unconnected chains that slide past each other, providing flexibility but lower durability and solvent resistance. Understanding the molecular architecture helps you choose materials tailored for applications requiring robust performance or flexibility.

Mechanical Properties Comparison

Crosslinked polymers exhibit superior mechanical properties compared to linear polymers, including enhanced tensile strength, elasticity, and resistance to deformation due to their three-dimensional network structure. Linear polymers tend to have lower mechanical strength and are more prone to plastic deformation under stress because their chains can slide past each other more easily. Your choice between crosslinked and linear polymers should consider the specific mechanical performance requirements of your application, such as durability and flexibility.

Thermal Stability and Resistance

Crosslinked polymers exhibit superior thermal stability and resistance compared to linear polymers due to their three-dimensional network structure, which restricts molecular motion and enhances heat resistance. This crosslinked network prevents polymer chains from sliding past each other under heat, resulting in higher decomposition temperatures and improved mechanical integrity at elevated temperatures. Linear polymers, lacking this interconnected architecture, tend to soften or melt at lower temperatures, making them less suitable for high-temperature applications.

Solubility and Swelling Behavior

Crosslinked polymers exhibit limited solubility in solvents due to their three-dimensional network structure, which restricts polymer chain mobility, while linear polymers dissolve more readily as their chains can separate and disperse throughout the solvent. When exposed to solvents, crosslinked polymers swell by absorbing liquid without dissolving, increasing in volume depending on the crosslink density and solvent affinity, whereas linear polymers typically dissolve completely without swelling behavior. Your choice between crosslinked and linear polymers affects applications requiring controlled solvent interaction, such as hydrogels or coatings.

Common Applications of Both Polymer Types

Crosslinked polymers are commonly used in applications requiring high mechanical strength and thermal stability, such as automotive parts, adhesives, and coatings. Linear polymers are prevalent in flexible packaging, textiles, and disposable products due to their ease of processing and recyclability. Your choice between crosslinked and linear polymers depends on the desired durability and flexibility for specific applications.

Advantages and Disadvantages

Crosslinked polymers offer superior mechanical strength, chemical resistance, and thermal stability compared to linear polymers due to their three-dimensional network structure, making them ideal for applications requiring durability and rigidity. However, their inability to be reshaped or melted limits recyclability and processing flexibility, posing challenges in manufacturing and end-of-life disposal. Your choice between crosslinked and linear polymers depends on the balance between desired performance characteristics and ease of processing or recycling.

Future Trends in Polymer Design

Future trends in polymer design emphasize the development of crosslinked polymers for enhanced mechanical strength, thermal stability, and chemical resistance compared to linear polymers. Innovations in dynamic crosslinking enable self-healing materials and recyclability, addressing sustainability challenges in advanced applications. You can expect continued growth in smart polymer systems integrating crosslinking techniques to tailor performance for biomedical, automotive, and electronics industries.

Crosslinked polymer vs linear polymer Infographic

libmatt.com

libmatt.com