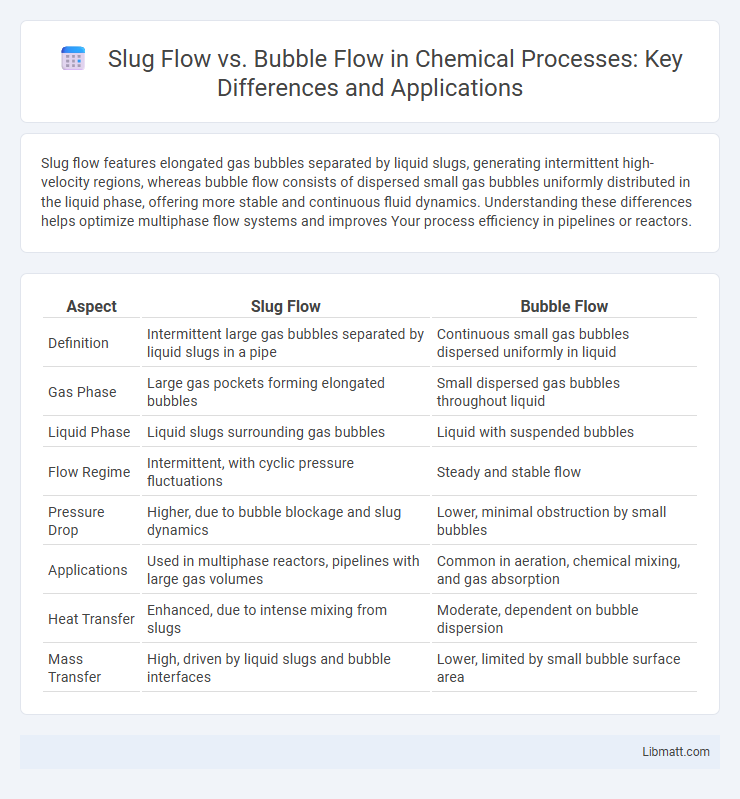

Slug flow features elongated gas bubbles separated by liquid slugs, generating intermittent high-velocity regions, whereas bubble flow consists of dispersed small gas bubbles uniformly distributed in the liquid phase, offering more stable and continuous fluid dynamics. Understanding these differences helps optimize multiphase flow systems and improves Your process efficiency in pipelines or reactors.

Table of Comparison

| Aspect | Slug Flow | Bubble Flow |

|---|---|---|

| Definition | Intermittent large gas bubbles separated by liquid slugs in a pipe | Continuous small gas bubbles dispersed uniformly in liquid |

| Gas Phase | Large gas pockets forming elongated bubbles | Small dispersed gas bubbles throughout liquid |

| Liquid Phase | Liquid slugs surrounding gas bubbles | Liquid with suspended bubbles |

| Flow Regime | Intermittent, with cyclic pressure fluctuations | Steady and stable flow |

| Pressure Drop | Higher, due to bubble blockage and slug dynamics | Lower, minimal obstruction by small bubbles |

| Applications | Used in multiphase reactors, pipelines with large gas volumes | Common in aeration, chemical mixing, and gas absorption |

| Heat Transfer | Enhanced, due to intense mixing from slugs | Moderate, dependent on bubble dispersion |

| Mass Transfer | High, driven by liquid slugs and bubble interfaces | Lower, limited by small bubble surface area |

Introduction to Two-Phase Flow Patterns

Two-phase flow patterns such as slug flow and bubble flow represent distinct regimes in multiphase fluid dynamics characterized by the distribution and interaction of gas and liquid phases. Slug flow features large gas bubbles separated by liquid slugs, creating intermittent high-velocity flow regions that impact pressure drop and heat transfer. Bubble flow consists of small, dispersed gas bubbles uniformly distributed in the continuous liquid phase, influencing mass transfer rates and flow stability, essential factors for optimizing your industrial multiphase flow systems.

Defining Slug Flow and Bubble Flow

Slug flow is a multiphase flow pattern characterized by elongated gas bubbles separated by liquid slugs, commonly observed in horizontal pipes during gas-liquid transport. Bubble flow consists of dispersed small gas bubbles uniformly distributed within the continuous liquid phase, typically appearing at lower gas velocities. The distinction between slug flow and bubble flow lies in bubble size, distribution, and flow regime, significantly impacting pressure drop and phase holdup in multiphase pipelines.

Visual Differences Between Slug and Bubble Flow

Slug flow features large, elongated gas pockets that nearly fill the pipe diameter, separated by liquid slugs, creating distinct, alternating sections of gas and liquid. In contrast, bubble flow consists of small, dispersed gas bubbles uniformly distributed within the continuous liquid phase, resulting in a more homogeneous and less segmented visual appearance. The stark size difference and distribution pattern of gas phases between slug and bubble flow are key visual indicators for their identification in multiphase flow systems.

Key Parameters Influencing Flow Regimes

Key parameters influencing slug flow and bubble flow regimes include fluid velocity, gas-liquid ratio, pipe diameter, and fluid properties such as viscosity and density. In slug flow, higher gas volume fractions and velocity fluctuations create intermittent large gas bubbles, while bubble flow features dispersed small gas bubbles due to lower velocities and reduced gas fractions. Understanding how these parameters interact helps you predict flow behavior in multiphase systems, optimizing process design and operational efficiency.

Flow Regime Transitions: Slug to Bubble

Flow regime transitions from slug flow to bubble flow occur as the gas velocity increases and liquid holdup decreases, causing discrete bubbles to form instead of elongated gas pockets. The transition is influenced by parameters like superficial gas velocity, liquid Reynolds number, and pipe inclination, impacting pressure drop and mass transfer rates. Understanding these shifts is crucial for optimizing multiphase flow systems in oil and gas pipelines, chemical reactors, and heat exchangers.

Effects on Pressure Drop and Flow Stability

Slug flow causes significant pressure fluctuations due to the alternating presence of liquid slugs and gas bubbles, resulting in higher pressure drops and reduced flow stability. Bubble flow maintains a more uniform distribution of gas bubbles in the liquid, leading to lower pressure drop and enhanced flow stability compared to slug flow. Understanding these differences helps you optimize pipeline designs to minimize energy losses and ensure steady operation.

Industrial Applications of Slug and Bubble Flow

Slug flow and bubble flow are essential multiphase flow patterns with distinct industrial applications that optimize fluid transport and mixing processes. Slug flow is commonly utilized in oil and gas pipelines to enhance efficiency in the transportation of gas-liquid mixtures by minimizing pressure fluctuations and ensuring steady flow. Bubble flow is prevalent in chemical reactors and wastewater treatment systems, where its fine gas dispersion improves mass transfer and reaction rates, boosting process performance.

Measurement Techniques for Flow Pattern Identification

Measurement techniques for slug flow and bubble flow identification primarily involve advanced sensor technologies like ultrasonic and electrical impedance tomography, which capture the distinct phase distributions in pipelines. High-speed imaging combined with image processing algorithms provides accurate visualization and analysis of the flow regimes, differentiating slug flow's intermittent large bubbles from the dispersed small bubbles characteristic of bubble flow. Deploying these techniques allows you to monitor and optimize multiphase flow processes effectively in various industrial applications.

Challenges and Limitations of Each Flow Type

Slug flow presents challenges such as increased pressure fluctuations and flow instability, which can cause pipeline vibrations and erosion issues. Bubble flow limitations include difficulty in maintaining consistent flow patterns and reduced mass transfer efficiency due to dispersed gas bubbles. Understanding these flow behaviors helps you optimize system design and minimize operational risks associated with multiphase fluid transport.

Conclusion: Choosing the Right Flow Regime

Choosing the right flow regime between slug flow and bubble flow depends on your specific application requirements, such as pressure drop, heat transfer, and fluid mixing efficiency. Slug flow offers higher mixing intensity and pressure fluctuations, making it suitable for processes needing enhanced mass transfer, while bubble flow provides a more stable and uniform flow ideal for gentle reactions and minimizing shear stress. Assessing the operational conditions and desired outcomes helps optimize system performance by selecting the flow regime that aligns with your process goals.

slug flow vs bubble flow Infographic

libmatt.com

libmatt.com