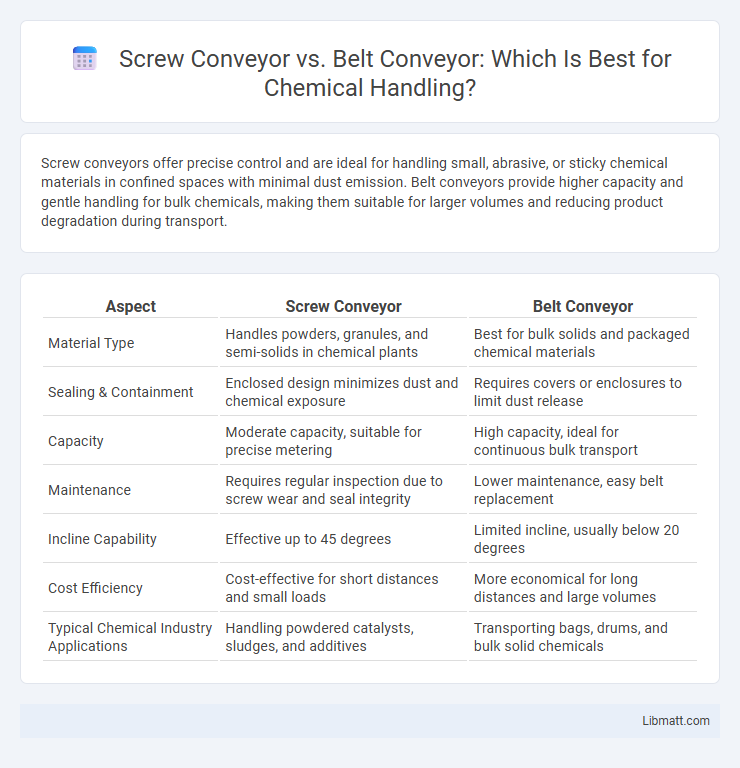

Screw conveyors offer precise control and are ideal for handling small, abrasive, or sticky chemical materials in confined spaces with minimal dust emission. Belt conveyors provide higher capacity and gentle handling for bulk chemicals, making them suitable for larger volumes and reducing product degradation during transport.

Table of Comparison

| Aspect | Screw Conveyor | Belt Conveyor |

|---|---|---|

| Material Type | Handles powders, granules, and semi-solids in chemical plants | Best for bulk solids and packaged chemical materials |

| Sealing & Containment | Enclosed design minimizes dust and chemical exposure | Requires covers or enclosures to limit dust release |

| Capacity | Moderate capacity, suitable for precise metering | High capacity, ideal for continuous bulk transport |

| Maintenance | Requires regular inspection due to screw wear and seal integrity | Lower maintenance, easy belt replacement |

| Incline Capability | Effective up to 45 degrees | Limited incline, usually below 20 degrees |

| Cost Efficiency | Cost-effective for short distances and small loads | More economical for long distances and large volumes |

| Typical Chemical Industry Applications | Handling powdered catalysts, sludges, and additives | Transporting bags, drums, and bulk solid chemicals |

Introduction to Conveyors in Chemical Handling

Screw conveyors and belt conveyors play crucial roles in chemical handling by efficiently transporting bulk materials with minimal spillage and contamination. Screw conveyors are ideal for precise, enclosed material transfer, reducing exposure to hazardous chemicals, while belt conveyors offer higher capacity and flexibility for continuous bulk movement over longer distances. Understanding your specific material properties and handling requirements is essential to select the optimal conveyor type for safe and efficient chemical processing.

Overview of Screw Conveyors

Screw conveyors in chemical handling are designed for efficient transport of powders, granules, and viscous materials within enclosed systems, minimizing contamination and spillage. Their helical screw design allows precise control over material flow rate and can handle abrasive or corrosive substances when constructed from specialized materials like stainless steel. Compared to belt conveyors, screw conveyors offer compact installation and are better suited for metering and mixing applications in chemical processing industries.

Overview of Belt Conveyors

Belt conveyors in chemical handling are designed to transport bulk materials efficiently, offering a continuous, smooth flow suitable for powders, granules, and small particles. They provide advantages such as low maintenance, ability to handle corrosive or abrasive chemicals with appropriate belt materials, and customizable configurations to fit specific plant layouts. Belt conveyors maintain minimal product degradation and contamination risk, making them ideal for sensitive chemical substances.

Material Handling Capabilities

Screw conveyors are ideal for precise handling of abrasive, viscous, or sticky chemicals due to their enclosed design and controlled movement, minimizing material degradation and dust generation. Belt conveyors excel in transporting bulk chemical powders and granules over longer distances at higher speeds with minimal product degradation. Both systems offer customizable options to handle moisture-sensitive or corrosive materials effectively, but screw conveyors provide better containment and sealing for hazardous chemical environments.

Efficiency and Throughput Comparisons

Screw conveyors offer moderate efficiency for chemical handling with consistent throughput, ideal for precise or small to medium volume material transfers. Belt conveyors provide higher throughput capacity and greater energy efficiency in bulk chemical transport, especially over longer distances. Material characteristics and handling requirements ultimately influence the optimal conveyor choice for maximizing operational efficiency.

Suitability for Different Chemical Types

Screw conveyors are ideal for handling viscous, sticky, or fine chemical powders due to their enclosed design and ability to control material flow, minimizing exposure and contamination. Belt conveyors suit granular or bulk chemicals with larger particle sizes, offering gentle transport and easy cleaning for corrosive substances. Your choice depends on the chemical's physical properties, flowability, and the need for containment during transfer.

Maintenance Requirements and Costs

Screw conveyors require regular inspection and replacement of worn flights and bearings to prevent leaks and contamination in chemical handling, often resulting in moderate maintenance costs. Belt conveyors demand frequent belt checks, tension adjustments, and roller replacements to avoid spillage and maintain operational efficiency, which can lead to higher ongoing maintenance expenses. Your choice between screw and belt conveyors should consider these maintenance requirements to optimize cost-effectiveness and reliability in chemical processing environments.

Safety Considerations in Chemical Conveyance

Screw conveyors offer enclosed handling, minimizing exposure to hazardous chemicals and reducing the risk of spills or contamination, which enhances safety in chemical processing environments. Belt conveyors provide easier access for inspection and cleaning but require proper guarding and ventilation to control dust and vapors, preventing potential health hazards. Selecting the right conveyor depends on your facility's chemical characteristics, prioritizing containment and operator safety during chemical conveyance.

Environmental Impact and Containment

Screw conveyors provide superior containment by minimizing dust and spillage during chemical handling, reducing environmental contamination risks. Belt conveyors, while efficient for moving bulk materials, often have higher dust emissions and potential leakage points that require additional containment measures. Your choice should consider the specific chemical properties and environmental regulations to ensure optimal containment and minimal ecological impact.

Choosing the Right Conveyor for Chemical Applications

Selecting the right conveyor for chemical handling hinges on material compatibility and contamination risk; screw conveyors excel at managing powders and granules while minimizing dust, whereas belt conveyors offer gentle transport for bulkier, less abrasive chemicals. Corrosion-resistant materials like stainless steel and specialized coatings are critical for both types to withstand aggressive chemicals and ensure longevity. Understanding the chemical's physical properties and environmental conditions guides the optimal conveyor choice, balancing efficiency, safety, and maintenance requirements.

Screw conveyor vs belt conveyor (chemical handling) Infographic

libmatt.com

libmatt.com