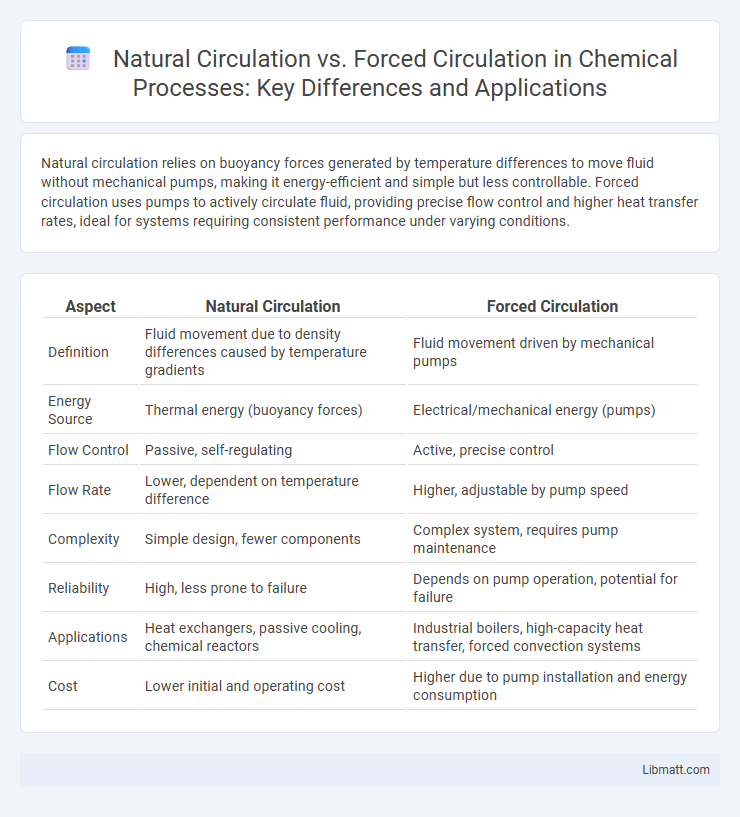

Natural circulation relies on buoyancy forces generated by temperature differences to move fluid without mechanical pumps, making it energy-efficient and simple but less controllable. Forced circulation uses pumps to actively circulate fluid, providing precise flow control and higher heat transfer rates, ideal for systems requiring consistent performance under varying conditions.

Table of Comparison

| Aspect | Natural Circulation | Forced Circulation |

|---|---|---|

| Definition | Fluid movement due to density differences caused by temperature gradients | Fluid movement driven by mechanical pumps |

| Energy Source | Thermal energy (buoyancy forces) | Electrical/mechanical energy (pumps) |

| Flow Control | Passive, self-regulating | Active, precise control |

| Flow Rate | Lower, dependent on temperature difference | Higher, adjustable by pump speed |

| Complexity | Simple design, fewer components | Complex system, requires pump maintenance |

| Reliability | High, less prone to failure | Depends on pump operation, potential for failure |

| Applications | Heat exchangers, passive cooling, chemical reactors | Industrial boilers, high-capacity heat transfer, forced convection systems |

| Cost | Lower initial and operating cost | Higher due to pump installation and energy consumption |

Introduction to Circulation Systems

Natural circulation systems rely on buoyancy forces caused by temperature differences to circulate fluids without mechanical pumps, making them energy-efficient and low-maintenance. Forced circulation systems use mechanical pumps to actively move fluids, providing precise flow control and higher circulation rates essential for complex industrial processes. Understanding the differences between these systems helps you select the most suitable method for applications like heating, cooling, or power generation.

Definition of Natural Circulation

Natural circulation refers to the flow of fluid driven by density differences due to temperature variations within a system, without the use of external pumps or mechanical devices. This phenomenon is commonly observed in heating and cooling systems, where warmer fluid rises and cooler fluid descends, creating a continuous circulation loop. Natural circulation is essential in applications such as solar water heaters, nuclear reactors, and HVAC systems for passive heat transfer and energy efficiency.

Definition of Forced Circulation

Forced circulation refers to the method of fluid movement in which pumps or external devices actively drive the flow of liquid through a system, ensuring consistent and controlled circulation regardless of density differences or temperature gradients. This technique contrasts with natural circulation, where fluid flow relies on buoyancy forces caused by temperature-induced density variations. Forced circulation is commonly used in industrial processes, heating systems, and cooling circuits to maintain precise flow rates and enhance thermal efficiency.

Key Differences Between Natural and Forced Circulation

Natural circulation relies on buoyancy-driven flow caused by density differences in the fluid due to temperature gradients, requiring no external power source, making it energy-efficient and simpler to maintain. Forced circulation uses pumps or mechanical devices to drive the fluid movement, providing faster, more controllable heat transfer and the ability to overcome gravity or longer piping systems. Your choice between natural and forced circulation depends on system complexity, required heat transfer rates, and energy consumption considerations.

Working Principles of Natural Circulation

Natural circulation relies on density differences caused by temperature gradients within the fluid to create a buoyancy-driven flow without mechanical pumps. Heated fluid becomes less dense and rises, while cooler, denser fluid descends, establishing a continuous circulation loop. This passive mechanism is crucial in systems like solar water heaters and nuclear reactors for maintaining fluid movement and heat transfer.

Working Principles of Forced Circulation

Forced circulation relies on mechanical pumps to actively drive the fluid through the system, ensuring consistent flow even against gravity or resistance. This method enhances heat transfer efficiency by maintaining controlled and uniform fluid velocity throughout the circuit. It enables precise regulation of temperature and pressure, making it ideal for complex cooling or heating applications.

Advantages of Natural Circulation

Natural circulation offers the advantage of enhanced system reliability due to the absence of mechanical components such as pumps, reducing maintenance requirements and operational costs. It leverages buoyancy-driven flow, which ensures passive cooling and safer operation in emergency conditions by minimizing the risk of pump failure. Your system benefits from improved energy efficiency since natural circulation operates without external power sources, promoting sustainable and eco-friendly performance.

Advantages of Forced Circulation

Forced circulation systems provide enhanced heat transfer efficiency by using pumps to maintain a consistent fluid flow, resulting in better temperature control and faster response times. These systems enable precise regulation of fluid velocity, reducing the risk of temperature stratification and improving overall performance in heat exchangers and boilers. Forced circulation is also advantageous in applications requiring higher pressure drops and fluid velocities, making it suitable for industrial processes with demanding thermal management needs.

Applications of Each Circulation Type

Natural circulation is commonly applied in systems where passive safety and low maintenance are essential, such as in solar water heaters, nuclear reactors' emergency cooling systems, and small-scale heating setups. Forced circulation is preferred in industrial boilers, HVAC systems, and large-scale power plants where precise control, higher flow rates, and efficient heat transfer are critical. Your choice between natural and forced circulation depends on factors like system size, energy consumption, and the need for operational control.

Conclusion: Choosing the Right Circulation System

Selecting the appropriate circulation system depends on the specific application, heat transfer requirements, and energy efficiency goals. Natural circulation systems offer simplicity and lower operational costs by relying on density differences to drive fluid flow, making them ideal for passive safety and low-maintenance needs. Forced circulation systems provide precise control over flow rates and heat removal, essential for high-performance industrial processes and applications demanding rapid thermal response.

natural circulation vs forced circulation Infographic

libmatt.com

libmatt.com