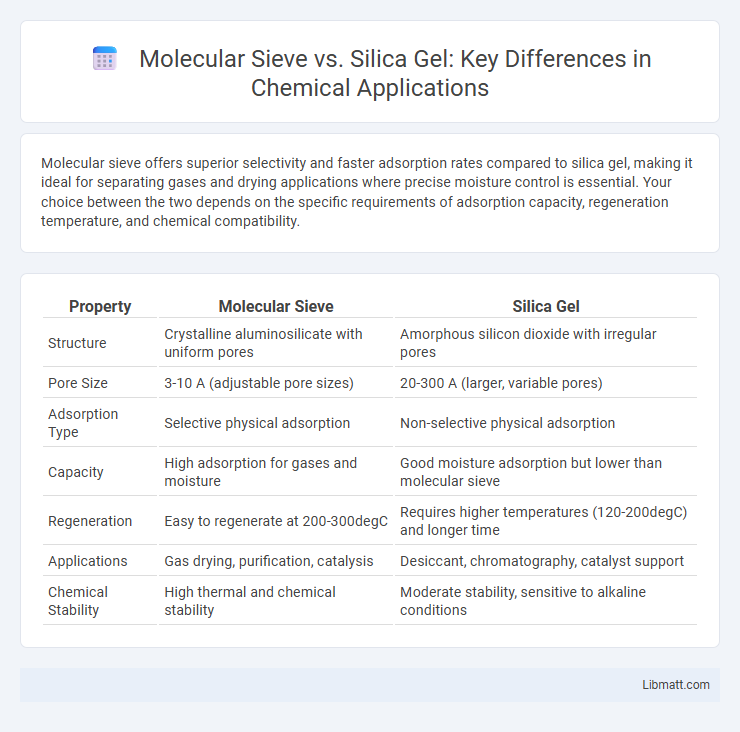

Molecular sieve offers superior selectivity and faster adsorption rates compared to silica gel, making it ideal for separating gases and drying applications where precise moisture control is essential. Your choice between the two depends on the specific requirements of adsorption capacity, regeneration temperature, and chemical compatibility.

Table of Comparison

| Property | Molecular Sieve | Silica Gel |

|---|---|---|

| Structure | Crystalline aluminosilicate with uniform pores | Amorphous silicon dioxide with irregular pores |

| Pore Size | 3-10 A (adjustable pore sizes) | 20-300 A (larger, variable pores) |

| Adsorption Type | Selective physical adsorption | Non-selective physical adsorption |

| Capacity | High adsorption for gases and moisture | Good moisture adsorption but lower than molecular sieve |

| Regeneration | Easy to regenerate at 200-300degC | Requires higher temperatures (120-200degC) and longer time |

| Applications | Gas drying, purification, catalysis | Desiccant, chromatography, catalyst support |

| Chemical Stability | High thermal and chemical stability | Moderate stability, sensitive to alkaline conditions |

Introduction to Desiccants: Molecular Sieve vs Silica Gel

Molecular sieves are crystalline aluminosilicates with uniform pore sizes that selectively adsorb molecules based on size and polarity, making them highly efficient for moisture removal in industrial applications. Silica gel consists of amorphous silicon dioxide with a porous structure that adsorbs moisture primarily through physical adsorption, commonly used in packaging and small-scale desiccation. Both desiccants are essential for humidity control, with molecular sieves offering superior adsorption capacity at lower temperatures and silica gel providing cost-effective moisture control in moderate conditions.

Chemical Composition and Structure

Molecular sieves are crystalline aluminosilicates composed of a three-dimensional framework of silicon, aluminum, and oxygen atoms forming uniform micropores, enabling selective adsorption based on molecular size. Silica gel consists of amorphous silicon dioxide (SiO2) with a porous structure characterized by irregular surface pores, providing high surface area but less precise molecular discrimination. The ordered structure of molecular sieves allows for tailored pore sizes, while silica gel's porous network is more variable, influencing their respective adsorption properties and applications.

Moisture Adsorption Mechanisms

Molecular sieves utilize a crystalline aluminosilicate framework with uniform pore sizes, allowing selective adsorption of water molecules through physical adsorption and ion-dipole interactions. Silica gel relies on a highly porous amorphous silica structure with silanol groups that adsorb moisture primarily via hydrogen bonding and capillary condensation. Both agents effectively reduce humidity but differ in adsorption capacity, regeneration temperature, and selectivity due to their distinct moisture adsorption mechanisms.

Pore Size and Selectivity Comparison

Molecular sieves possess uniform pore sizes typically ranging from 3 to 10 angstroms, enabling precise selective adsorption based on molecular dimensions, whereas silica gel exhibits a broader pore size distribution between 20 to 300 angstroms, offering less specificity. The selectivity of molecular sieves derives from their crystalline aluminosilicate framework, which selectively adsorbs molecules of specific sizes and shapes, compared to the amorphous silicate network of silica gel that adsorbs molecules primarily through surface area and polarity interactions. As a result, molecular sieves are preferred in applications requiring high selectivity for gases and small molecules, while silica gel suits broader moisture adsorption needs.

Adsorption Capacity and Efficiency

Molecular sieves exhibit higher adsorption capacity and efficiency compared to silica gel due to their uniform pore size and ability to selectively adsorb gases and moisture molecules based on molecular dimensions. Silica gel has a broader pore size distribution, resulting in less selective adsorption and lower overall efficiency for removing moisture in specific industrial applications. Molecular sieves are particularly effective in low humidity and high-temperature environments, maintaining superior performance in moisture adsorption and gas purification processes.

Regeneration and Reusability

Molecular sieves exhibit superior regeneration capabilities through high-temperature thermal treatment, allowing for repeated reuse without significant loss of adsorption efficiency, making them ideal for demanding industrial applications. Silica gel undergoes moisture desorption at lower temperatures but experiences gradual degradation and reduced adsorption capacity over multiple cycles. Your choice between molecular sieve and silica gel should consider the frequency of regeneration and the operational temperature range to optimize long-term performance.

Application Areas and Industry Uses

Molecular sieves excel in gas purification, petrochemical refining, and drying of liquids due to their precise pore sizes, making them ideal for removing water and impurities from natural gas and air separation processes. Silica gel is widely used in pharmaceuticals, food packaging, and electronics for moisture control and humidity regulation, protecting sensitive products from degradation. Both materials serve critical roles in industrial drying and adsorption, but molecular sieves offer higher selectivity in complex chemical environments.

Performance Under Different Environmental Conditions

Molecular sieves exhibit superior performance over silica gel in high humidity and low temperature environments due to their ability to adsorb water molecules more selectively and efficiently. Silica gel performs adequately in moderate conditions but loses effectiveness when exposed to saturated or highly humid atmospheres. Optimizing your drying or purification process involves selecting molecular sieves for challenging environments where consistent adsorption capacity is critical.

Cost Analysis and Economic Considerations

Molecular sieves typically have a higher initial cost compared to silica gel due to their advanced pore structure and regeneration capacity, which can provide long-term savings in industrial drying applications. Silica gel offers a lower upfront investment but may require more frequent replacement or regeneration, increasing operational expenses over time. Evaluating your specific application's drying requirements and regeneration frequency will help determine the most cost-effective option between these two adsorbents.

Choosing the Optimal Desiccant: Key Takeaways

Choosing the optimal desiccant depends on your moisture adsorption needs and operating conditions. Molecular sieves offer superior adsorption at low humidity levels and higher temperatures due to their uniform pore sizes, making them ideal for industrial gas drying. Silica gel is more cost-effective and works well for general purpose moisture control, especially in environments with moderate humidity and room temperature applications.

molecular sieve vs silica gel Infographic

libmatt.com

libmatt.com