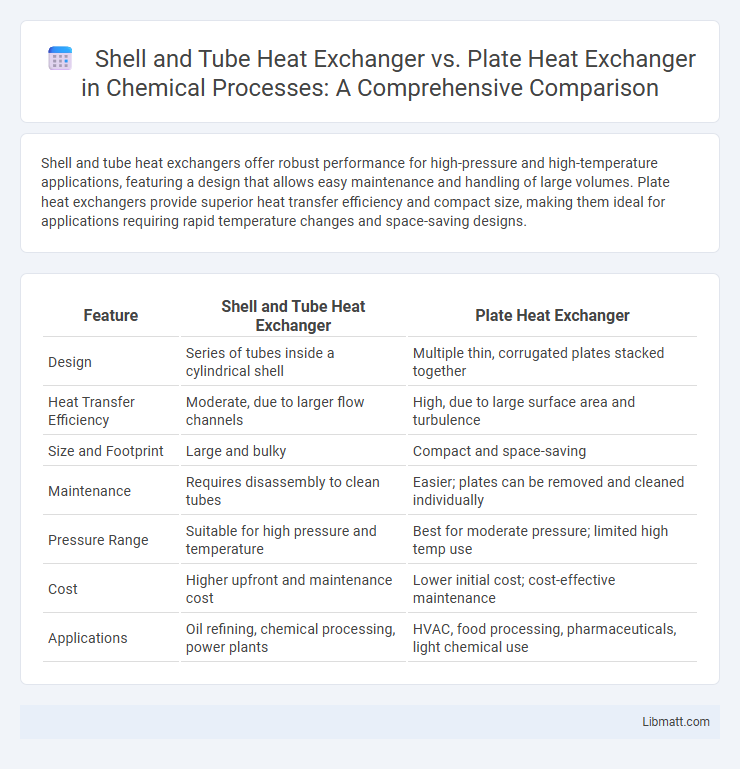

Shell and tube heat exchangers offer robust performance for high-pressure and high-temperature applications, featuring a design that allows easy maintenance and handling of large volumes. Plate heat exchangers provide superior heat transfer efficiency and compact size, making them ideal for applications requiring rapid temperature changes and space-saving designs.

Table of Comparison

| Feature | Shell and Tube Heat Exchanger | Plate Heat Exchanger |

|---|---|---|

| Design | Series of tubes inside a cylindrical shell | Multiple thin, corrugated plates stacked together |

| Heat Transfer Efficiency | Moderate, due to larger flow channels | High, due to large surface area and turbulence |

| Size and Footprint | Large and bulky | Compact and space-saving |

| Maintenance | Requires disassembly to clean tubes | Easier; plates can be removed and cleaned individually |

| Pressure Range | Suitable for high pressure and temperature | Best for moderate pressure; limited high temp use |

| Cost | Higher upfront and maintenance cost | Lower initial cost; cost-effective maintenance |

| Applications | Oil refining, chemical processing, power plants | HVAC, food processing, pharmaceuticals, light chemical use |

Introduction to Heat Exchangers

Heat exchangers are essential devices used to transfer heat between two or more fluids without mixing them, commonly employed in industries such as HVAC, chemical processing, and power generation. Shell and tube heat exchangers consist of a series of tubes, one set carrying the hot fluid and the other the cold fluid, offering high-pressure tolerance and suitability for high-temperature applications. Plate heat exchangers feature thin, corrugated plates that provide a large surface area for heat transfer, resulting in compact size and high thermal efficiency, making them ideal for space-constrained environments.

Overview of Shell and Tube Heat Exchangers

Shell and tube heat exchangers consist of a series of tubes enclosed within a cylindrical shell, allowing efficient heat transfer between two fluids at different temperatures. These exchangers are widely used in industries such as chemical processing, power generation, and oil refining due to their robustness and ability to handle high pressure and temperature conditions. Their design supports easy maintenance and scalability, making them ideal for applications requiring large heat transfer areas and durability.

Overview of Plate Heat Exchangers

Plate heat exchangers consist of multiple thin, corrugated metal plates stacked to create a high surface area for efficient heat transfer between fluids. They offer compact design, easy maintenance, and superior thermal performance compared to shell and tube heat exchangers, making them ideal for applications with space constraints and frequent cleaning requirements. The enhanced turbulence generated by the corrugated plates improves heat transfer rates while minimizing fouling and pressure drop.

Design Differences: Shell and Tube vs Plate

The design of shell and tube heat exchangers features a series of tubes enclosed within a cylindrical shell, allowing fluid to flow inside the tubes while another fluid flows around them, optimizing heat transfer in high-pressure applications. Plate heat exchangers consist of multiple thin, corrugated plates stacked together, creating narrow channels that enhance heat transfer efficiency and allow easier cleaning and maintenance. Your choice depends on factors like space availability, thermal performance, and maintenance requirements, as shell and tube units are more robust for large-scale industrial processes, whereas plate exchangers excel in compactness and heat transfer rates.

Heat Transfer Efficiency Comparison

Shell and tube heat exchangers typically offer lower heat transfer efficiency due to larger fluid volumes and lower surface area contact between the fluids. Plate heat exchangers provide significantly higher heat transfer efficiency by utilizing thin, corrugated plates that increase surface area and promote turbulent flow, enhancing thermal performance. The compact design and reduced fluid hold-up of plate heat exchangers result in faster temperature changes and improved overall heat transfer rates.

Maintenance and Cleaning Considerations

Shell and tube heat exchangers require periodic cleaning through mechanical or chemical methods due to their complex internal tubing, which can trap fouling and reduce heat transfer efficiency. Plate heat exchangers offer easier maintenance with removable plates that allow for quick inspection and cleaning, making them suitable for processes requiring frequent sanitation. The choice depends on the application's fouling tendency, accessibility, and downtime constraints.

Space and Installation Requirements

Shell and tube heat exchangers demand significant space due to their bulky design and extensive piping, making installation more complex and time-consuming. Plate heat exchangers offer a compact footprint with modular plates that facilitate easier installation and reduce the required floor area. Choosing a plate heat exchanger can optimize your space utilization and simplify installation in tight plant environments.

Cost Analysis: Initial and Operational

Shell and tube heat exchangers typically have a higher initial cost due to their robust construction and suitability for high-pressure applications, while plate heat exchangers offer lower upfront expenses thanks to their compact design and ease of manufacturing. Operational costs of shell and tube exchangers tend to be higher because of greater energy consumption and more complex maintenance requirements, whereas plate heat exchangers provide better heat transfer efficiency, reducing energy costs and simplifying cleaning processes. Your choice should consider the balance between initial investment and long-term operational savings based on your specific application needs.

Typical Applications for Each Type

Shell and tube heat exchangers are typically used in heavy-duty industries such as oil refining, power generation, and chemical processing due to their ability to handle high pressures and temperatures. Plate heat exchangers are favored in HVAC systems, food and beverage processing, and pharmaceutical applications where efficiency, compact size, and easy maintenance are critical. Each type excels in specific operating conditions, with shell and tube offering durability for extreme environments and plate heat exchangers providing higher heat transfer rates in less space.

Choosing the Right Heat Exchanger for Your Needs

Shell and tube heat exchangers offer robust performance for high-pressure applications and handle large temperature differences, making them ideal for industrial processes with heavy-duty requirements. Plate heat exchangers provide a compact design with high heat transfer efficiency and easy maintenance, suitable for systems demanding quick temperature changes and space savings. Evaluate your system's pressure, temperature range, space constraints, and maintenance preferences to determine whether a shell and tube or plate heat exchanger best suits your needs.

shell and tube heat exchanger vs plate heat exchanger Infographic

libmatt.com

libmatt.com