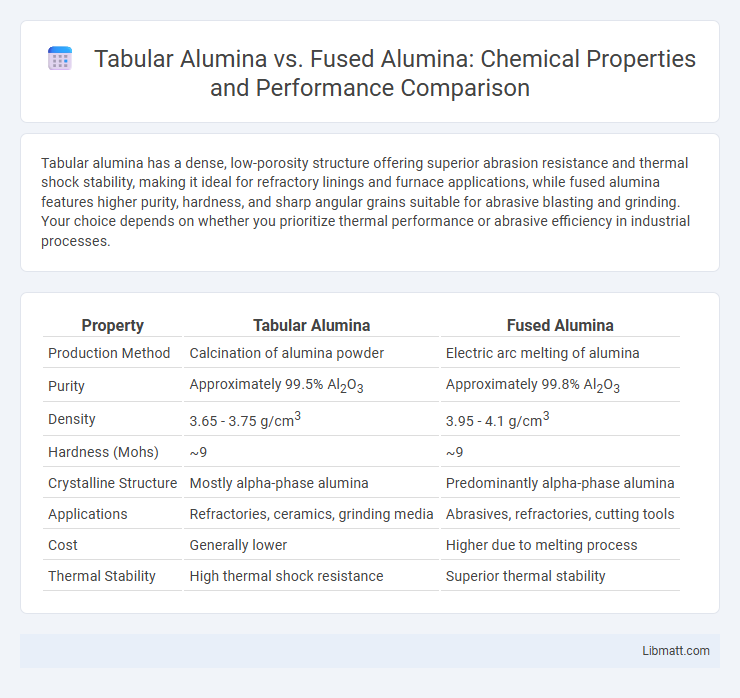

Tabular alumina has a dense, low-porosity structure offering superior abrasion resistance and thermal shock stability, making it ideal for refractory linings and furnace applications, while fused alumina features higher purity, hardness, and sharp angular grains suitable for abrasive blasting and grinding. Your choice depends on whether you prioritize thermal performance or abrasive efficiency in industrial processes.

Table of Comparison

| Property | Tabular Alumina | Fused Alumina |

|---|---|---|

| Production Method | Calcination of alumina powder | Electric arc melting of alumina |

| Purity | Approximately 99.5% Al2O3 | Approximately 99.8% Al2O3 |

| Density | 3.65 - 3.75 g/cm3 | 3.95 - 4.1 g/cm3 |

| Hardness (Mohs) | ~9 | ~9 |

| Crystalline Structure | Mostly alpha-phase alumina | Predominantly alpha-phase alumina |

| Applications | Refractories, ceramics, grinding media | Abrasives, refractories, cutting tools |

| Cost | Generally lower | Higher due to melting process |

| Thermal Stability | High thermal shock resistance | Superior thermal stability |

Introduction to Tabular Alumina and Fused Alumina

Tabular alumina is a dense, angular, and coarse crystalline form of aluminum oxide produced by the fusion of bauxite in electric arc furnaces, known for its high density and thermal stability. Fused alumina, also called fused aluminum oxide, is created by melting alumina at high temperatures, resulting in a harder and more abrasive material ideal for grinding and cutting applications. Your choice between these materials depends on the desired thermal properties, hardness, and application requirements in industries like refractories and abrasives.

Raw Material Sources and Manufacturing Processes

Tabular alumina is produced by sintering high-purity calcined alumina at temperatures above 1600degC, utilizing bauxite or aluminum hydroxide as primary raw materials, resulting in a dense, angular microstructure. Fused alumina is manufactured by melting alumina feedstock, often derived from bauxite or aluminum scrap, in an electric arc furnace at temperatures exceeding 2000degC, followed by rapid cooling to create hard, sharp-edged particles. The distinct manufacturing processes influence the physical properties, with tabular alumina exhibiting higher density and fused alumina characterized by superior hardness and toughness.

Physical Properties Comparison

Tabular alumina exhibits a dense, coarse-grained microstructure with high hardness and excellent thermal stability, making it ideal for refractory applications requiring abrasion resistance. Fused alumina, produced by melting and rapid cooling, has a jagged, sharp grain shape contributing to superior cutting and grinding efficiency but slightly lower density and thermal shock resistance than tabular alumina. Your choice depends on whether you prioritize mechanical strength and thermal stability (tabular alumina) or abrasive performance and sharpness (fused alumina).

Chemical Composition Differences

Tabular alumina is primarily composed of alumina (Al2O3) with very low levels of impurities such as silica, iron oxide, and calcium oxide, resulting in high purity and excellent refractory properties. Fused alumina, produced by melting bauxite in an electric arc furnace, contains higher impurity levels like silica and titanium dioxide, impacting its strength and abrasion resistance. You should select tabular alumina when chemical stability and purity are critical for high-temperature applications.

Performance in High-Temperature Environments

Tabular alumina exhibits superior thermal stability and resistance to thermal shock compared to fused alumina, making it ideal for high-temperature environments such as kiln linings and refractory applications. Fused alumina, while hard and wear-resistant, has a lower refractoriness and can degrade more quickly under extreme heat. You should select tabular alumina when performance, durability, and longevity at elevated temperatures are critical.

Mechanical Strength and Durability

Tabular alumina exhibits superior mechanical strength due to its dense, angular grain structure, making it highly resistant to abrasion and impact in industrial applications. Fused alumina, while also strong, is characterized by a more irregular and porous microstructure, which can result in slightly lower durability under high-stress conditions. The enhanced toughness and wear resistance of tabular alumina make it preferable for demanding environments such as refractory linings and grinding media.

Applications in Refractory Industries

Tabular alumina features high purity, low impurity levels, and excellent thermal stability, making it ideal for refractory linings in steelmaking furnaces and kiln furniture. Fused alumina, characterized by its angular particles and lower purity, offers superior abrasion resistance and is widely used in grinding media and blast furnace linings. Your choice depends on the specific thermal and mechanical demands of the refractory application, with tabular alumina favored for heat-intensive environments and fused alumina preferred where wear resistance is critical.

Cost Analysis and Economic Considerations

Tabular alumina generally incurs higher production costs due to its complex manufacturing process involving high-temperature sintering, leading to increased energy consumption. Fused alumina, produced by melting alumina oxide, offers a more cost-efficient alternative with lower energy requirements and faster production rates, making it suitable for budget-conscious applications. When evaluating your options, consider that tabular alumina's superior density and hardness yield longer service life, which may offset its initial price in long-term economic assessments.

Advantages and Limitations of Each Alumina Type

Tabular alumina offers high density, excellent thermal shock resistance, and superior mechanical strength, making it ideal for refractory applications requiring durability and thermal stability. Fused alumina provides higher purity and hardness, enhancing its effectiveness in abrasive materials and cutting tools, but its brittleness can limit impact resistance. Tabular alumina's cost-effectiveness and energy-efficient production contrast with fused alumina's higher energy consumption and expense, influencing material selection based on application-specific performance criteria.

Choosing the Right Alumina for Industrial Applications

Tabular alumina and fused alumina differ primarily in their manufacturing processes and physical properties, impacting their suitability in industrial applications. Tabular alumina, created by the fusion of bauxite at high temperatures, offers high density, excellent thermal shock resistance, and low impurity levels, making it ideal for refractory linings and kiln furniture in steel and cement industries. Your choice should consider factors like abrasion resistance, thermal stability, and cost-efficiency, with fused alumina being preferred for grinding and abrasive applications due to its higher purity and hardness.

Tabular alumina vs fused alumina Infographic

libmatt.com

libmatt.com