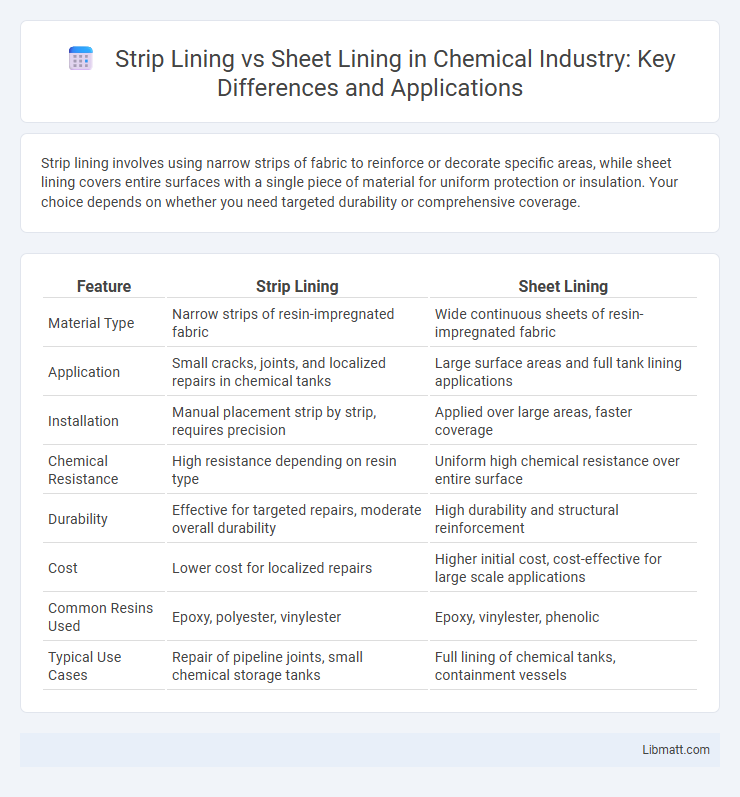

Strip lining involves using narrow strips of fabric to reinforce or decorate specific areas, while sheet lining covers entire surfaces with a single piece of material for uniform protection or insulation. Your choice depends on whether you need targeted durability or comprehensive coverage.

Table of Comparison

| Feature | Strip Lining | Sheet Lining |

|---|---|---|

| Material Type | Narrow strips of resin-impregnated fabric | Wide continuous sheets of resin-impregnated fabric |

| Application | Small cracks, joints, and localized repairs in chemical tanks | Large surface areas and full tank lining applications |

| Installation | Manual placement strip by strip, requires precision | Applied over large areas, faster coverage |

| Chemical Resistance | High resistance depending on resin type | Uniform high chemical resistance over entire surface |

| Durability | Effective for targeted repairs, moderate overall durability | High durability and structural reinforcement |

| Cost | Lower cost for localized repairs | Higher initial cost, cost-effective for large scale applications |

| Common Resins Used | Epoxy, polyester, vinylester | Epoxy, vinylester, phenolic |

| Typical Use Cases | Repair of pipeline joints, small chemical storage tanks | Full lining of chemical tanks, containment vessels |

Introduction to Strip Lining and Sheet Lining

Strip lining involves inserting narrow, flexible materials into pipeline defects to create a durable seal, often used for repairing localized cracks or corrosion. Sheet lining utilizes larger, continuous sheets designed to cover extensive pipe surfaces, offering a comprehensive barrier against corrosion and leaks. Your choice between strip lining and sheet lining depends on the extent of damage and the specific pipeline requirements.

What is Strip Lining?

Strip lining involves inserting narrow, pre-fabricated strips of material into pipe interiors to repair localized sections of damage, offering a cost-effective and less invasive alternative to full pipe replacement. This method targets specific cracked or corroded areas, enhancing the pipe's structural integrity and extending its service life. Your plumbing system benefits from minimal downtime and reduced disruption compared to sheet lining, which covers larger surface areas.

What is Sheet Lining?

Sheet lining is a roofing method that uses large, continuous sheets of waterproof material, such as bitumen or synthetic membranes, to create a seamless barrier against water infiltration. This technique enhances roof durability and reduces the risk of leaks compared to strip lining, which involves narrower, overlapping strips. You can improve your roofing system's efficiency and longevity by choosing sheet lining for a more uniform and robust protective layer.

Key Differences Between Strip Lining and Sheet Lining

Strip lining involves inserting narrow, pre-formed liners into damaged pipes to create a new, corrosion-resistant interior surface, while sheet lining uses large rolls of flexible, cured-in-place material to cover extensive pipe sections. Strip lining is ideal for small-scale repairs or localized defects, offering quicker installation with minimal pipe diameter reduction, whereas sheet lining suits larger pipelines or irregularly shaped pipes, providing continuous coverage and enhanced structural reinforcement. Both methods improve pipeline longevity but differ in application scale, flexibility, and installation complexity.

Material Selection for Strip and Sheet Lining

Material selection for strip lining typically involves flexible materials such as rubber or fabric strips coated with epoxy or polyurethane, chosen for their ability to conform to irregular surfaces and provide localized reinforcement. Sheet lining uses larger, continuous materials like fiberglass, carbon fiber, or Kevlar composite sheets that offer high tensile strength and corrosion resistance, ideal for extensive surface coverage and structural enhancement. Your choice depends on the specific application requirements, surface conditions, and desired durability of the lining system.

Advantages of Strip Lining

Strip lining offers precise reinforcement for timber elements, allowing targeted strengthening without extensive material usage. This method preserves the original structure's integrity by minimizing invasive procedures and reducing overall project costs. Your renovation benefits from improved load-bearing capacity and easier installation compared to sheet lining alternatives.

Advantages of Sheet Lining

Sheet lining offers superior structural reinforcement by providing continuous coverage that effectively resists groundwater infiltration and soil movement. It enhances pipeline durability with materials like HDPE or PVC, ensuring long-term corrosion resistance and flexibility under varying pressure conditions. This method reduces installation time and maintenance costs compared to segmental strip lining, making it an efficient solution for trenchless sewer rehabilitation.

Applications of Strip Lining vs Sheet Lining

Strip lining is primarily used for localized pipeline repairs, targeting cracks, corrosion spots, or small leaks in water mains and sewage lines, offering a cost-effective solution with minimal service interruption. Sheet lining, on the other hand, is ideal for rehabilitating entire pipe sections or larger areas, providing structural reinforcement and corrosion protection in applications such as stormwater drains, culverts, and industrial pipelines. Both methods enhance pipeline longevity, but strip lining suits targeted fixes while sheet lining addresses extensive rehabilitation needs.

Cost Comparison: Strip Lining vs Sheet Lining

Strip lining typically incurs lower upfront costs due to its targeted application, making it cost-effective for localized pipe repairs. Sheet lining, while generally more expensive initially, offers comprehensive pipe rehabilitation by lining larger sections, reducing long-term maintenance expenses. Analyzing project scale and pipe condition is essential to determine the most cost-efficient method between strip lining and sheet lining.

Choosing the Right Lining Method for Your Project

Strip lining offers a cost-effective solution with easy installation, ideal for smaller or irregularly shaped surfaces, while sheet lining provides superior durability and uniform protection suited for larger or more demanding projects. Your choice depends on factors such as project size, budget, and required longevity, with sheet lining often preferred for high-traffic areas due to its seamless, robust barrier. Assessing the specific needs of your project ensures optimal performance and long-term satisfaction.

Strip lining vs sheet lining Infographic

libmatt.com

libmatt.com