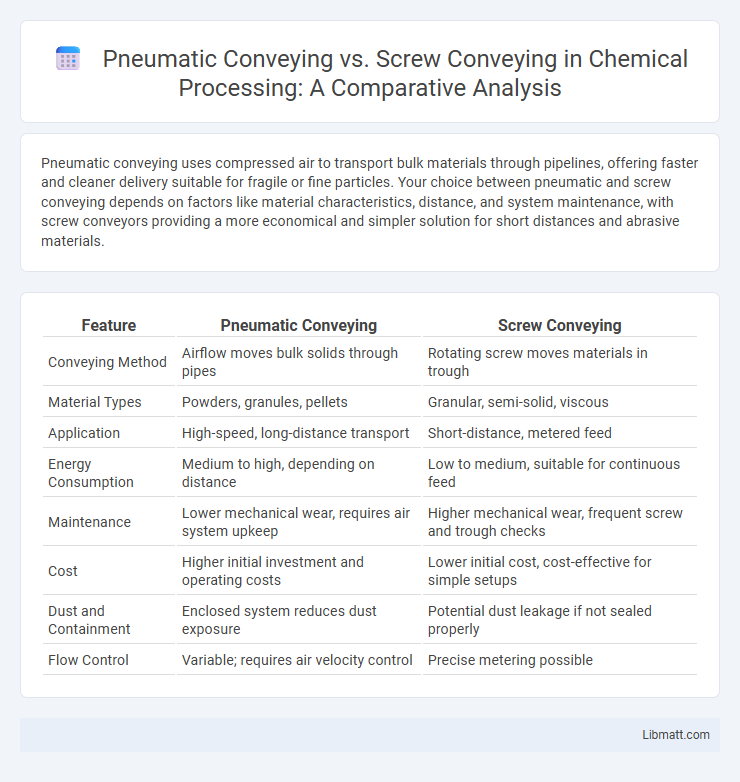

Pneumatic conveying uses compressed air to transport bulk materials through pipelines, offering faster and cleaner delivery suitable for fragile or fine particles. Your choice between pneumatic and screw conveying depends on factors like material characteristics, distance, and system maintenance, with screw conveyors providing a more economical and simpler solution for short distances and abrasive materials.

Table of Comparison

| Feature | Pneumatic Conveying | Screw Conveying |

|---|---|---|

| Conveying Method | Airflow moves bulk solids through pipes | Rotating screw moves materials in trough |

| Material Types | Powders, granules, pellets | Granular, semi-solid, viscous |

| Application | High-speed, long-distance transport | Short-distance, metered feed |

| Energy Consumption | Medium to high, depending on distance | Low to medium, suitable for continuous feed |

| Maintenance | Lower mechanical wear, requires air system upkeep | Higher mechanical wear, frequent screw and trough checks |

| Cost | Higher initial investment and operating costs | Lower initial cost, cost-effective for simple setups |

| Dust and Containment | Enclosed system reduces dust exposure | Potential dust leakage if not sealed properly |

| Flow Control | Variable; requires air velocity control | Precise metering possible |

Introduction to Pneumatic and Screw Conveying

Pneumatic conveying transports bulk materials through pipelines using pressurized air or vacuum, offering rapid and enclosed movement ideal for powders and granules. Screw conveying relies on a rotating helical screw blade within a tube to move materials mechanically, suited for short distances and viscous substances. Both systems optimize material handling efficiency but differ in energy consumption, maintenance requirements, and applicability based on material characteristics.

Key Principles of Pneumatic Conveying

Pneumatic conveying uses a stream of air or gas to transport bulk materials through pipelines, relying on pressure or vacuum to move particles efficiently over long distances and complex routes. The key principles involve controlling air velocity, pressure, and flow rate to prevent material degradation and system blockages while maintaining consistent delivery. Your choice of pneumatic conveying ensures flexibility and cleanliness, making it ideal for handling fine powders and fragile materials compared to screw conveying's mechanical push method.

Key Principles of Screw Conveying

Screw conveying operates on the key principle of a rotating helical screw blade, or auger, which moves bulk materials through a fixed trough or enclosed tube. This mechanical action efficiently transports granular, powder, or semi-solid materials by pushing them forward along the conveyance path, with precise control over flow rate and volume. Your choice of screw conveying ensures consistent handling of materials with minimal degradation, making it suited for dense or abrasive substances where pneumatic systems may struggle.

Material Suitability: Pneumatic vs Screw Systems

Pneumatic conveying systems are ideal for handling fine, dry, and abrasive materials such as powders, grains, and pellets, offering minimal contamination and efficient dust control. Screw conveyors excel in transporting semi-solid materials, granules, and bulk solids with consistent flow, especially when materials are abrasive, sticky, or have irregular shapes. Material characteristics such as particle size, moisture content, and abrasiveness determine the optimal choice between pneumatic and screw conveying systems for maximum efficiency and product integrity.

Energy Efficiency Comparison

Pneumatic conveying systems typically consume more energy than screw conveying due to the power needed to maintain high air velocity for material transport. Screw conveyors operate at lower power levels by mechanically moving materials with rotating screws, resulting in energy efficiency that can reduce operational costs. Comparing typical energy usage, pneumatic systems can require up to 2-3 times greater power per ton of material conveyed compared to screw conveyors.

Installation and Maintenance Differences

Pneumatic conveying systems require extensive ductwork and air compressors, leading to more complex and space-demanding installations compared to screw conveyors, which involve straightforward mechanical setups with troughs and screw augers. Maintenance of pneumatic systems often involves checking air filters, blowers, and seals for wear or damage, while screw conveyors primarily require inspection of bearings, shafts, and screw blades to prevent material buildup and mechanical failure. Pneumatic systems typically have higher operational costs due to air leakage and wear on moving parts, whereas screw conveyors have lower energy consumption and simpler troubleshooting processes.

Dust Control and Environmental Impact

Pneumatic conveying significantly reduces dust emission by transporting materials through sealed pipelines, preventing airborne particles and enhancing environmental safety. Screw conveying tends to generate more dust due to its open design, increasing the risk of particulate release into the environment. Choosing pneumatic conveying for Your material handling needs helps minimize dust pollution and supports cleaner air quality compliance.

Cost Analysis: Initial and Operational Expenses

Pneumatic conveying systems generally incur higher initial costs due to complex equipment like blowers, filters, and pipelines, whereas screw conveying typically demands lower upfront investment with simpler mechanical components. Operational expenses for pneumatic conveying are often elevated because of substantial energy consumption and maintenance for air handling units, while screw conveyors benefit from lower power requirements and easier maintenance but may have higher wear rates depending on material abrasiveness. Evaluating total cost of ownership requires consideration of factors such as material characteristics, throughput rates, and installation complexity, which significantly influence both capital and ongoing operational expenditures.

Application Scenarios and Industry Usage

Pneumatic conveying excels in industries requiring contamination-free, dust-controlled transfer of bulk materials, such as food processing, pharmaceuticals, and chemical manufacturing, where materials are transported through pipelines using air pressure or vacuum. Screw conveying is ideal for handling abrasive, sticky, or fragile materials in industries like agriculture, wastewater treatment, and construction, providing consistent metering and gentle material movement through rotating helical screws. Your choice depends on factors like material characteristics, transfer distance, and industry-specific hygiene standards, making pneumatic conveying suited for long-distance and clean applications, while screw conveying fits short-distance, robust material handling.

Choosing the Right Conveying System for Your Needs

Pneumatic conveying offers efficient, dust-free transport of bulk materials over long distances using compressed air, ideal for delicate or hazardous powders. Screw conveying provides reliable, low-maintenance material handling with precise metering capabilities, best suited for heavier, granular products in shorter distances. Your choice depends on factors like material type, distance, and environmental considerations to ensure optimal performance and cost-efficiency.

Pneumatic conveying vs screw conveying Infographic

libmatt.com

libmatt.com