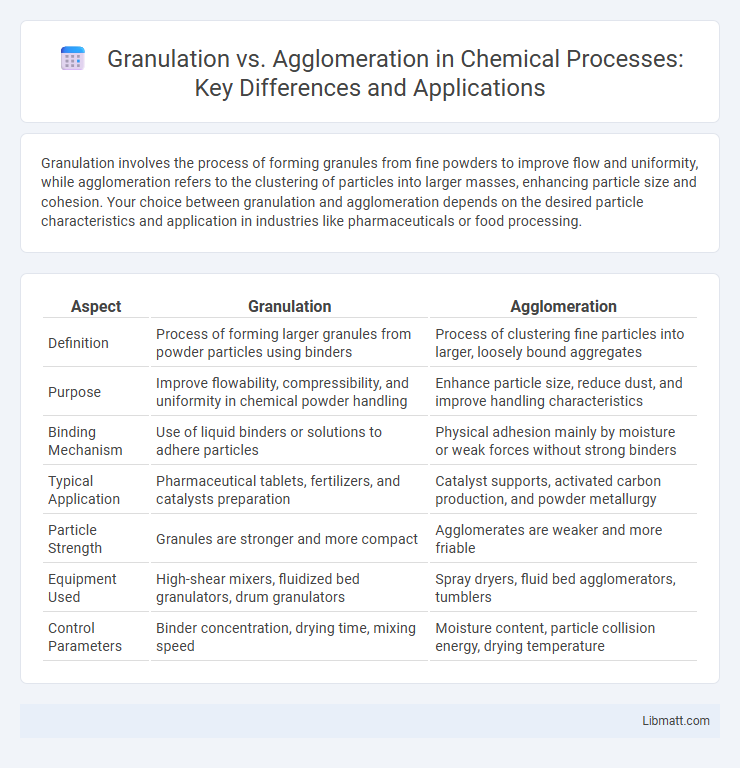

Granulation involves the process of forming granules from fine powders to improve flow and uniformity, while agglomeration refers to the clustering of particles into larger masses, enhancing particle size and cohesion. Your choice between granulation and agglomeration depends on the desired particle characteristics and application in industries like pharmaceuticals or food processing.

Table of Comparison

| Aspect | Granulation | Agglomeration |

|---|---|---|

| Definition | Process of forming larger granules from powder particles using binders | Process of clustering fine particles into larger, loosely bound aggregates |

| Purpose | Improve flowability, compressibility, and uniformity in chemical powder handling | Enhance particle size, reduce dust, and improve handling characteristics |

| Binding Mechanism | Use of liquid binders or solutions to adhere particles | Physical adhesion mainly by moisture or weak forces without strong binders |

| Typical Application | Pharmaceutical tablets, fertilizers, and catalysts preparation | Catalyst supports, activated carbon production, and powder metallurgy |

| Particle Strength | Granules are stronger and more compact | Agglomerates are weaker and more friable |

| Equipment Used | High-shear mixers, fluidized bed granulators, drum granulators | Spray dryers, fluid bed agglomerators, tumblers |

| Control Parameters | Binder concentration, drying time, mixing speed | Moisture content, particle collision energy, drying temperature |

Understanding Granulation: Definition and Process

Granulation is a process that converts fine powders into larger, multi-particle entities called granules by binding particles together using a liquid binder. This method improves powder flowability, compressibility, and homogeneity, essential in pharmaceutical and industrial applications. Understanding your material's properties is crucial to selecting the appropriate granulation technique for optimal product performance.

What is Agglomeration? A Detailed Overview

Agglomeration is a process in particle technology where fine particles adhere to form larger, multi-particle entities, enhancing material handling and flow properties in industries like pharmaceuticals and food processing. This technique improves particle size distribution and increases bulk density by using mechanisms such as wetting, vibration, or compaction. Unlike granulation, which often involves forming granules for tablets, agglomeration focuses on creating uniform, porous clusters that optimize dissolution rates and reduce dust generation.

Key Differences Between Granulation and Agglomeration

Granulation involves the process of forming grains or granules from a powdery substance, primarily using binders and moisture to enhance particle size and uniformity, whereas agglomeration is the process of clustering smaller particles into larger masses using mechanical force or adhesive agents. Granulation typically produces more uniform and dense granules suited for tablet manufacturing, while agglomeration creates porous, irregular particles useful in applications like drying and fluidization. Understanding these distinctions helps you select the appropriate technique for optimizing material properties and manufacturing efficiency.

Types of Granulation Techniques

Granulation techniques primarily include wet granulation, dry granulation, and spray granulation, each offering unique advantages based on moisture sensitivity and material properties. Wet granulation uses a liquid binder to form granules, enhancing compressibility and flowability, ideal for heat-sensitive drugs. Dry granulation, utilizing compaction methods such as slugging or roller compaction, avoids moisture exposure, suitable for moisture-sensitive compounds, while spray granulation involves atomizing liquid binders onto powders, offering precise control over particle size distribution.

Common Methods of Agglomeration

Common methods of agglomeration include spray drying, drum granulation, and fluidized bed agglomeration, each offering unique advantages in particle size control and product uniformity. Spray drying transforms liquid feed into dry granules rapidly, ideal for heat-sensitive materials, while drum granulation uses tumbling action to form larger particles from powders. Fluidized bed agglomeration enhances granule strength and flow properties by fluidizing particles and binding them with a sprayed liquid, supporting Your need for consistent and efficient powder processing.

Applications of Granulation in Industry

Granulation finds extensive applications in pharmaceutical manufacturing, where it enhances powder flowability and tablet uniformity, crucial for consistent drug delivery. In the fertilizer industry, granulation improves nutrient distribution and handling efficiency, directly impacting crop yield and sustainability. Your production processes benefit from granulation by achieving better particle size control and reduced dust generation in various sectors like food, chemicals, and mining.

Industrial Uses of Agglomeration

Agglomeration plays a crucial role in industries such as pharmaceuticals, food processing, and chemical manufacturing by enhancing particle size and improving flow properties. Your production process benefits from its ability to create uniform granules that enhance product consistency and solubility. Industrial agglomeration techniques optimize material handling, reduce dust generation, and increase bulk density, leading to better packaging and transportation efficiency.

Advantages of Granulation Processes

Granulation processes offer improved powder flowability and reduced dust generation, enhancing both safety and handling efficiency in manufacturing environments. You benefit from increased compressibility and uniform particle size distribution, which lead to consistent tablet quality and dissolution rates. These advantages make granulation a preferred choice for pharmaceutical production and various industrial applications requiring precise particulate control.

Benefits and Limitations of Agglomeration

Agglomeration offers enhanced flowability and improved particle size distribution, leading to better compaction and uniformity in pharmaceutical and chemical processes. However, it requires precise control over moisture content and binder addition to prevent issues like overgrowth or weak granules, which can affect product performance. The technique is cost-effective for large-scale production but may incur higher energy and equipment costs compared to simple granulation.

Choosing Between Granulation and Agglomeration: Factors to Consider

Choosing between granulation and agglomeration depends on factors such as particle size uniformity, process efficiency, and the desired end-product characteristics. Granulation is preferred for achieving precise control over particle size and density, improving flowability and reducing dust in pharmaceutical formulations. Your selection should also consider equipment availability, moisture content, and application requirements to ensure optimal production outcomes.

Granulation vs agglomeration Infographic

libmatt.com

libmatt.com