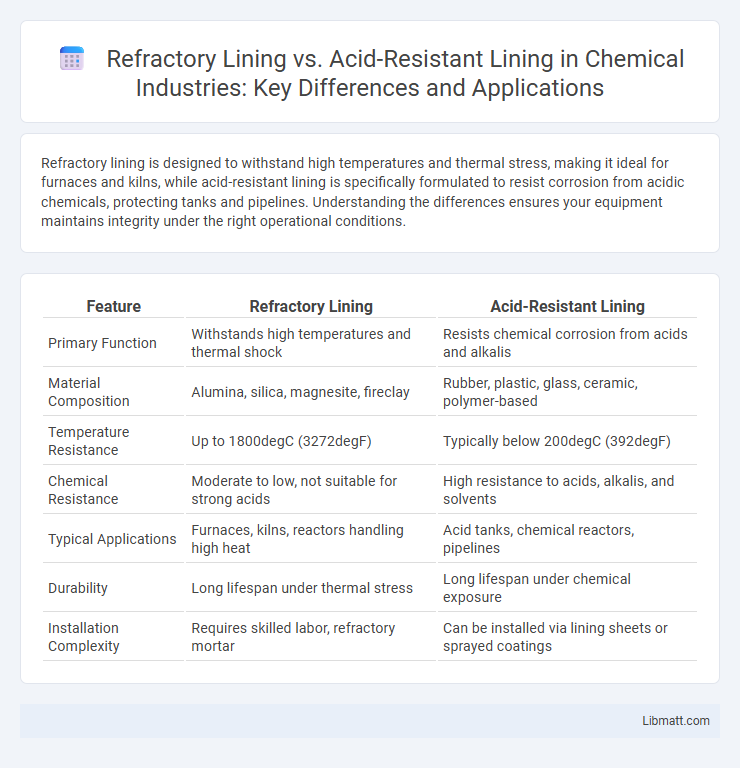

Refractory lining is designed to withstand high temperatures and thermal stress, making it ideal for furnaces and kilns, while acid-resistant lining is specifically formulated to resist corrosion from acidic chemicals, protecting tanks and pipelines. Understanding the differences ensures your equipment maintains integrity under the right operational conditions.

Table of Comparison

| Feature | Refractory Lining | Acid-Resistant Lining |

|---|---|---|

| Primary Function | Withstands high temperatures and thermal shock | Resists chemical corrosion from acids and alkalis |

| Material Composition | Alumina, silica, magnesite, fireclay | Rubber, plastic, glass, ceramic, polymer-based |

| Temperature Resistance | Up to 1800degC (3272degF) | Typically below 200degC (392degF) |

| Chemical Resistance | Moderate to low, not suitable for strong acids | High resistance to acids, alkalis, and solvents |

| Typical Applications | Furnaces, kilns, reactors handling high heat | Acid tanks, chemical reactors, pipelines |

| Durability | Long lifespan under thermal stress | Long lifespan under chemical exposure |

| Installation Complexity | Requires skilled labor, refractory mortar | Can be installed via lining sheets or sprayed coatings |

Introduction to Industrial Linings

Refractory lining and acid-resistant lining serve distinct roles in industrial applications, designed to protect equipment from high temperatures and corrosive substances respectively. Refractory linings are primarily used in furnaces, kilns, and reactors to withstand extreme heat, while acid-resistant linings are applied in chemical plants and storage tanks to prevent damage from acidic environments. Understanding these linings helps you select the optimal protection tailored to your operational needs and prolong the lifespan of your industrial assets.

Defining Refractory Lining

Refractory lining is a specialized material designed to withstand high temperatures, often used in furnaces, kilns, and reactors to protect structural components from heat damage. Unlike acid-resistant lining, which primarily guards against chemical corrosion, refractory lining must maintain thermal stability and mechanical strength under extreme heat. Understanding the unique properties of refractory lining helps ensure your equipment operates safely and efficiently in high-temperature environments.

Understanding Acid-Resistant Lining

Acid-resistant lining is specifically designed to protect equipment and structures from corrosive chemical attacks, especially from strong acids like sulfuric and hydrochloric acid, ensuring long-term durability in harsh industrial environments. Unlike refractory lining, which primarily withstands high temperatures and thermal stress, acid-resistant lining focuses on chemical resistance and preventing material degradation caused by acidic substances. You should choose acid-resistant lining when chemical corrosion is a primary concern to maintain safety and operational efficiency in processing units.

Key Material Compositions

Refractory lining primarily consists of high-temperature resistant materials such as alumina, silica, and magnesite, designed to withstand extreme heat and thermal shock in industrial furnaces and kilns. Acid-resistant lining typically uses materials like rubber, plastic, and specialized acid-resistant bricks composed of silica and fireclay to protect equipment from corrosive chemical attacks. Your choice depends on the operating environment, with refractory linings favored for heat endurance and acid-resistant linings essential for chemical corrosion protection.

Performance in High-Temperature Environments

Refractory lining offers superior thermal insulation and stability in high-temperature environments, typically withstanding temperatures above 1,200degC, making it ideal for furnaces, kilns, and reactors. Acid-resistant lining, while excellent for corrosion resistance against acidic substances, generally operates effectively at lower temperatures, often below 600degC. Choosing the right lining depends on your operational heat exposure and chemical environment to ensure optimal performance and longevity.

Chemical Resistance Comparison

Refractory lining exhibits superior resistance to high-temperature chemical corrosion, making it ideal for environments involving molten metal and slags, while acid-resistant lining is specifically engineered to withstand strong acids and chemical attacks at lower temperatures. The chemical resistance of refractory linings is primarily effective against alkaline substances and slag, whereas acid-resistant linings protect equipment from sulfuric, hydrochloric, and nitric acid exposure. Selecting between refractory and acid-resistant linings depends on the chemical composition and operating temperature of the industrial process involved.

Common Applications of Refractory Linings

Refractory linings are widely used in high-temperature industrial environments such as steel manufacturing, cement kilns, and glass production where they protect equipment from extreme heat and thermal shock. These linings typically consist of materials like fireclay, silica, and alumina, engineered to withstand temperatures above 1600degC. Their ability to maintain structural integrity under intense heat makes them essential for furnaces, boilers, and incinerators in heavy industries.

Typical Uses of Acid-Resistant Linings

Acid-resistant linings are typically used in environments where chemical corrosion and acid exposure are prevalent, such as in chemical processing plants, wastewater treatment facilities, and acid storage tanks. These linings protect equipment from aggressive acids like sulfuric, hydrochloric, and phosphoric acid, ensuring durability and safety. Your choice of acid-resistant lining can significantly extend the lifespan of industrial vessels and piping systems exposed to harsh acidic conditions.

Installation and Maintenance Differences

Refractory linings require high-temperature curing and careful drying processes during installation to prevent cracking and ensure structural integrity, while acid-resistant linings are often applied using chemical curing methods tailored for corrosive resistance. Maintenance of refractory linings involves regular inspections for thermal spalling and mechanical wear, whereas acid-resistant linings demand monitoring for chemical degradation and surface erosion. The installation complexity and specialized maintenance protocols reflect the material composition differences and operational environment of each lining type.

Choosing the Right Lining for Your Industry

Refractory lining and acid-resistant lining are essential for protecting industrial equipment from extreme heat and corrosive environments, respectively, making material selection crucial for optimal performance. Refractory linings, typically made from fireclay, alumina, or silicon carbide, withstand high temperatures in furnaces and kilns, while acid-resistant linings, composed of rubber, plastic, or specialized cement, provide superior chemical resistance in environments exposed to sulfuric or hydrochloric acid. Assessing industry-specific conditions such as operating temperature, chemical exposure, and mechanical wear ensures the right lining choice enhances durability, safety, and operational efficiency.

Refractory lining vs acid-resistant lining Infographic

libmatt.com

libmatt.com