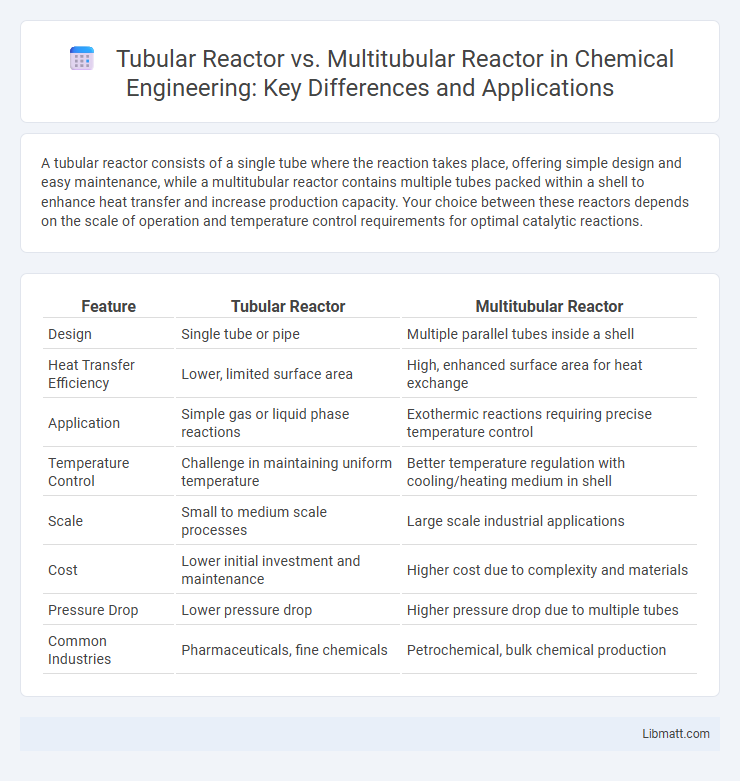

A tubular reactor consists of a single tube where the reaction takes place, offering simple design and easy maintenance, while a multitubular reactor contains multiple tubes packed within a shell to enhance heat transfer and increase production capacity. Your choice between these reactors depends on the scale of operation and temperature control requirements for optimal catalytic reactions.

Table of Comparison

| Feature | Tubular Reactor | Multitubular Reactor |

|---|---|---|

| Design | Single tube or pipe | Multiple parallel tubes inside a shell |

| Heat Transfer Efficiency | Lower, limited surface area | High, enhanced surface area for heat exchange |

| Application | Simple gas or liquid phase reactions | Exothermic reactions requiring precise temperature control |

| Temperature Control | Challenge in maintaining uniform temperature | Better temperature regulation with cooling/heating medium in shell |

| Scale | Small to medium scale processes | Large scale industrial applications |

| Cost | Lower initial investment and maintenance | Higher cost due to complexity and materials |

| Pressure Drop | Lower pressure drop | Higher pressure drop due to multiple tubes |

| Common Industries | Pharmaceuticals, fine chemicals | Petrochemical, bulk chemical production |

Overview of Tubular and Multitubular Reactors

Tubular reactors consist of a single tube where reactants flow continuously, offering simple design and ease of temperature control, ideal for gas-phase reactions and small-scale processes. Multitubular reactors contain multiple tubes within a shell, enhancing heat transfer and allowing for large-scale, high-throughput operations often used in exothermic reactions like catalytic hydrogenation or oxidation. Your choice between these reactors depends on factors like reaction kinetics, heat management requirements, and production scale.

Fundamental Design Differences

A tubular reactor consists of a single tube through which reactants flow, enabling simple heat transfer and reaction control, whereas a multitubular reactor contains numerous small tubes arranged within a shell, significantly increasing surface area for heat exchange and improving temperature regulation. Tubular reactors are ideal for reactions requiring uniform flow and straightforward scale-up, while multitubular reactors are preferred for highly exothermic reactions needing efficient thermal management to prevent hot spots. The multitubular design enhances catalyst contact and allows for better temperature gradient control, making it suitable for large-scale industrial applications.

Flow Dynamics and Mixing Patterns

Tubular reactors exhibit plug flow behavior with minimal axial mixing, promoting uniform residence time and efficient heat transfer in simple reaction systems. Multitubular reactors consist of multiple small-diameter tubes arranged within a shell, enhancing surface area for heat exchange but introducing complex flow dynamics, including potential maldistribution and varied mixing patterns among tubes. The choice between tubular and multitubular reactors depends on reaction kinetics, heat removal requirements, and desired flow uniformity to optimize conversion and selectivity.

Heat Transfer Capabilities

Tubular reactors provide limited heat transfer due to their single tube design, often resulting in temperature gradients that affect reaction uniformity. Multitubular reactors enhance heat transfer capabilities significantly by housing multiple small-diameter tubes within a coolant jacket, increasing surface area and enabling efficient temperature control. This design allows for better management of exothermic or endothermic reactions, improving reaction rates and selectivity.

Reaction Efficiency and Yield

Tubular reactors offer high reaction efficiency for single-phase reactions by ensuring uniform temperature and laminar flow, which enhances yield consistency. Multitubular reactors improve heat transfer and accommodate higher throughput by using multiple small tubes within a shell, making them ideal for exothermic reactions requiring precise temperature control. Your choice between the two depends on the reaction scale and the need for efficient heat management to maximize yield.

Application Suitability

Tubular reactors are ideal for continuous flow processes involving homogeneous reactions and moderate heat transfer requirements, commonly used in small to medium-scale chemical synthesis. Multitubular reactors excel in large-scale applications requiring efficient heat removal, such as exothermic catalytic reactions in petrochemical and refinery industries. The multitubular design enhances heat transfer by distributing the reaction mixture across multiple tubes, improving temperature control and overall process safety.

Scalability and Industrial Implementation

Tubular reactors offer straightforward scalability through length adjustments but face limitations in heat transfer and pressure drop management at larger scales. Multitubular reactors enhance scalability by incorporating multiple tubes within a shell, enabling superior heat removal and uniform temperature profiles critical for exothermic reactions in industrial applications. Their design supports high throughput and operational flexibility, making multitubular reactors preferred in large-scale chemical production such as ammonia synthesis and hydrocracking.

Maintenance and Operational Considerations

Tubular reactors offer easier maintenance due to their simpler design, with straightforward cleaning and inspection processes, while multitubular reactors require more complex upkeep because of multiple tubes that can experience uneven fouling or corrosion. Operationally, multitubular reactors provide better heat management and higher throughput, but they demand careful monitoring to prevent tube failures and ensure uniform flow distribution. Your choice depends on balancing maintenance ease with operational efficiency according to process requirements.

Cost Implications and Economic Analysis

Tubular reactors generally involve lower initial capital costs due to simpler design and manufacturing processes, while multitubular reactors incur higher expenses from intricate construction and maintenance of multiple tubes. Economic analysis reveals that multitubular reactors offer enhanced heat transfer and greater surface area, improving conversion efficiency and product yield, which can offset higher upfront costs over time. Your choice should weigh the balance between immediate cost savings with tubular reactors and long-term operational benefits provided by multitubular designs.

Selection Criteria for Optimal Reactor Choice

Selection criteria for choosing between a tubular reactor and a multitubular reactor include reaction scale, heat transfer requirements, and catalyst protection. Tubular reactors are preferred for small-scale or low heat removal processes with straightforward temperature control, while multitubular reactors excel in large-scale operations requiring efficient heat dissipation due to their multiple catalyst-filled tubes surrounded by coolant. Factors such as pressure drop, ease of maintenance, and uniform temperature profiles also influence the optimal reactor choice for industrial chemical reactions.

Tubular reactor vs multitubular reactor Infographic

libmatt.com

libmatt.com