Shaft furnaces offer higher energy efficiency and faster processing times compared to rotary kilns, making them ideal for continuous operations in metallurgy and cement production. Your choice depends on material characteristics and production scale, with rotary kilns excelling in handling diverse feedstocks and complex thermal profiles.

Table of Comparison

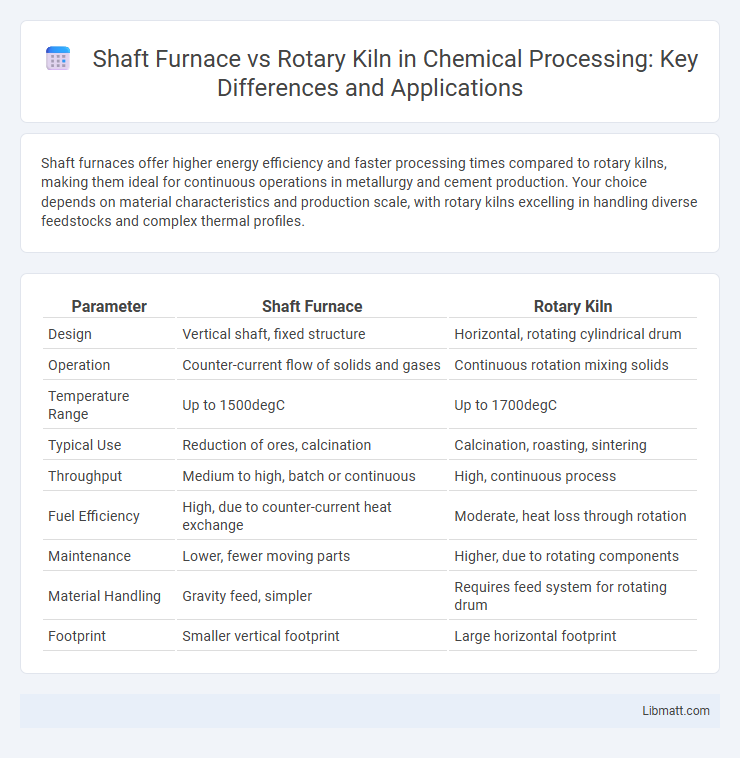

| Parameter | Shaft Furnace | Rotary Kiln |

|---|---|---|

| Design | Vertical shaft, fixed structure | Horizontal, rotating cylindrical drum |

| Operation | Counter-current flow of solids and gases | Continuous rotation mixing solids |

| Temperature Range | Up to 1500degC | Up to 1700degC |

| Typical Use | Reduction of ores, calcination | Calcination, roasting, sintering |

| Throughput | Medium to high, batch or continuous | High, continuous process |

| Fuel Efficiency | High, due to counter-current heat exchange | Moderate, heat loss through rotation |

| Maintenance | Lower, fewer moving parts | Higher, due to rotating components |

| Material Handling | Gravity feed, simpler | Requires feed system for rotating drum |

| Footprint | Smaller vertical footprint | Large horizontal footprint |

Introduction: Shaft Furnace vs Rotary Kiln

Shaft furnaces offer high thermal efficiency and shorter processing times by relying on vertical heat transfer, making them ideal for metallurgical applications like pelletizing iron ore. Rotary kilns provide versatile, continuous operation with uniform heat distribution, suitable for cement manufacturing and complex chemical reactions. Your choice depends on specific process requirements, energy consumption, and material properties to optimize production efficiency.

Basic Operating Principles

A shaft furnace operates by directing raw materials through a vertical shaft where they undergo gradual heating and chemical reactions as they descend, relying on countercurrent gas flow for efficient processing. A rotary kiln, in contrast, functions by rotating a slightly inclined cylindrical shell, allowing the material to move slowly through the heated zone while undergoing calcination or sintering. Understanding these basic operating principles can help you choose the right equipment for processes involving thermal treatment and material transformation.

Design and Structural Differences

Shaft furnaces feature a vertical design with a stationary structure, allowing raw materials to descend through the heating zones by gravity, optimizing heat transfer and fuel efficiency. Rotary kilns have a long, cylindrical, rotating structure inclined at a slight angle to facilitate continuous material movement, enabling uniform heat exposure and processing of larger material quantities. You should consider shaft furnaces for processes needing stratified temperature zones and rotary kilns for adaptable, high-capacity thermal treatment.

Energy Efficiency Comparison

Shaft furnaces typically exhibit higher energy efficiency than rotary kilns due to their counter-current heat exchange design, which recovers and reuses thermal energy effectively during the calcination process. Rotary kilns consume more fuel because of longer residence times and heat losses from their rotating shell and refractory lining. By choosing a shaft furnace, your operation can significantly reduce energy consumption and lower overall emissions in industrial calcination applications.

Material Processing Capabilities

Shaft furnaces excel in processing materials requiring indirect heating and oxidation, such as metallic ores and limestone, due to their counter-current gas flow and steady temperature zones. Rotary kilns handle a wider variety of feedstocks, including sludge, hazardous waste, and minerals, offering high temperature uniformity and mechanical agitation for clinker formation or waste thermal treatment. Your choice depends on the specific processing needs, such as the chemical reactions and thermal profiles essential for the material's transformation.

Environmental Impact and Emissions

Shaft furnaces produce lower emissions due to their efficient heat utilization and reduced fuel consumption compared to rotary kilns, which operate at higher temperatures and longer residence times, resulting in increased CO2 and particulate emissions. Rotary kilns often require more auxiliary fuel and generate greater amounts of nitrogen oxides (NOx) and sulfur oxides (SOx) due to their combustion processes. Environmental regulations increasingly favor shaft furnaces for their ability to minimize greenhouse gas emissions and optimize energy use in metallurgical applications.

Cost and Maintenance Considerations

Shaft furnaces generally offer lower operational costs and simpler maintenance due to their straightforward design and fewer moving parts compared to rotary kilns. Rotary kilns involve higher energy consumption and demand more frequent maintenance, including lubrication and wear-resistant lining replacement, which increases overall expenses. Choosing the right equipment depends on your specific production scale and budget constraints, balancing cost efficiency with maintenance requirements.

Industrial Applications and Suitability

Shaft furnaces excel in the production of metal oxides and refining processes, offering energy-efficient operation suitable for continuous processing of fine materials in industries like metallurgy and chemicals. Rotary kilns are preferred for high-temperature processing of bulk materials, including cement production, lime calcination, and waste incineration, due to their versatile design and ability to handle varying feedstock sizes. Your choice depends on factors such as feed material characteristics, temperature requirements, and desired output quality in industrial applications.

Advantages and Limitations

Shaft furnaces offer higher energy efficiency and lower maintenance costs due to their simpler design and better heat utilization, making them ideal for processing materials with consistent particle sizes. Rotary kilns provide greater flexibility in handling variable feed materials and allow for longer residence times, which improves processing uniformity but often results in higher energy consumption and increased wear. Your choice depends on balancing operational efficiency with feed variability and maintenance capabilities.

Conclusion: Choosing the Right Technology

Choosing between a shaft furnace and a rotary kiln depends on your specific production needs, raw material characteristics, and energy efficiency goals. Shaft furnaces offer higher thermal efficiency and lower fuel consumption for consistent feed materials, while rotary kilns provide greater flexibility for varying inputs and larger scale operations. Your decision should prioritize operational costs, product quality, and processing capacity to maximize overall performance.

Shaft furnace vs rotary kiln Infographic

libmatt.com

libmatt.com