Drum dryers and spray dryers both efficiently reduce moisture in liquids, but drum dryers use a heated rotating drum to dry thin films, ideal for pastes and viscous products, whereas spray dryers atomize liquids into fine droplets for rapid drying, suitable for heat-sensitive materials like milk powder. Your choice depends on product characteristics and desired powder quality, with spray drying offering finer, more uniform particles and drum drying producing flake-like solids.

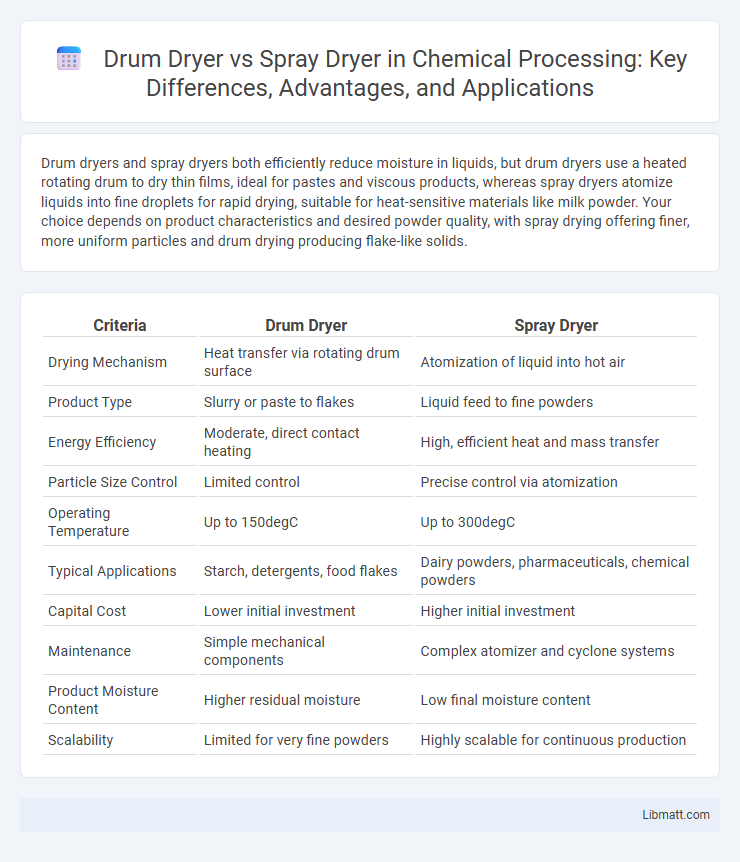

Table of Comparison

| Criteria | Drum Dryer | Spray Dryer |

|---|---|---|

| Drying Mechanism | Heat transfer via rotating drum surface | Atomization of liquid into hot air |

| Product Type | Slurry or paste to flakes | Liquid feed to fine powders |

| Energy Efficiency | Moderate, direct contact heating | High, efficient heat and mass transfer |

| Particle Size Control | Limited control | Precise control via atomization |

| Operating Temperature | Up to 150degC | Up to 300degC |

| Typical Applications | Starch, detergents, food flakes | Dairy powders, pharmaceuticals, chemical powders |

| Capital Cost | Lower initial investment | Higher initial investment |

| Maintenance | Simple mechanical components | Complex atomizer and cyclone systems |

| Product Moisture Content | Higher residual moisture | Low final moisture content |

| Scalability | Limited for very fine powders | Highly scalable for continuous production |

Overview of Drum Dryers

Drum dryers use a rotating heated drum to dry liquid or slurry by direct contact, providing rapid moisture removal with minimal thermal degradation. They are ideal for viscous materials, producing flaky or powdery dried products with uniform particle size and high bulk density. Drum dryers offer energy-efficient drying with lower operating costs compared to spray dryers, making them suitable for starches, chemicals, and food products like fruit purees and dairy.

Overview of Spray Dryers

Spray dryers rapidly convert liquid feed into dry powder by atomizing the liquid into a hot drying medium, ensuring efficient moisture removal and uniform particle size. This technology offers superior control over final product characteristics compared to drum dryers, making it ideal for heat-sensitive materials in pharmaceuticals, food, and chemicals. Your production process benefits from faster drying times and consistent quality, especially when handling temperature-sensitive substances.

Key Differences Between Drum and Spray Dryers

Drum dryers use a rotating heated drum to evaporate moisture, ideal for viscous or heat-sensitive materials, while spray dryers atomize liquid into fine droplets exposed to hot air, producing fine powders quickly. Drum dryers are energy-efficient for thick slurries, whereas spray dryers offer better control over particle size and uniformity. Your choice depends on the material properties and desired product characteristics, with spray dryers favored for rapid drying and higher-quality powders.

Working Principle: Drum Dryer

The working principle of a drum dryer involves spreading a liquid or slurry into a thin film on the surface of a heated rotating drum, where heat transfer occurs by conduction. As the drum rotates, moisture rapidly evaporates, leaving behind a dried product that is then scraped off by a blade. This method is highly efficient for drying viscous materials and produces flakes or powders with uniform moisture content.

Working Principle: Spray Dryer

Spray dryers work by atomizing a liquid feed into fine droplets and introducing them into a hot drying chamber, where rapid evaporation occurs due to high surface area exposure. The moisture in the droplets evaporates almost instantly, leaving behind dry powder particles that are collected from the air stream. Understanding your spray dryer's working principle helps optimize drying efficiency, product quality, and particle size distribution.

Advantages of Drum Dryers

Drum dryers offer advantages such as lower energy consumption and the ability to produce flake or sheet-like products with uniform thickness. They handle viscous materials and heat-sensitive products effectively due to shorter drying times and controlled temperature exposure. Your choice of a drum dryer ensures efficient processing for high-viscosity feeds and improved product quality.

Advantages of Spray Dryers

Spray dryers offer superior control over particle size and uniformity, resulting in high-quality powders with enhanced solubility and flow properties. They enable rapid drying of heat-sensitive materials, preserving your product's nutritional and functional qualities. This technology also supports continuous operation and automation, improving efficiency and scalability in industrial applications.

Limitations and Challenges of Each Dryer

Drum dryers face limitations such as uneven drying and lower product quality due to high-temperature exposure, which can degrade heat-sensitive materials and cause sticky residues that complicate cleaning. Spray dryers encounter challenges including high operational costs, complex maintenance, and difficulties in handling viscous or heat-sensitive liquids that may clog nozzles or result in incomplete drying. Both dryers require careful parameter optimization to balance drying efficiency with product integrity and energy consumption.

Typical Applications for Drum and Spray Dryers

Drum dryers are typically used for drying viscous liquids, pastes, and slurries such as fruit pulps, starches, and dairy products due to their ability to handle high viscosity materials efficiently. Spray dryers excel in producing fine, uniform powders from heat-sensitive liquids like milk powder, coffee, pharmaceuticals, and chemical solutions, offering precise control over particle size and moisture content. Your choice between drum and spray drying depends on the material characteristics and the desired final product properties, with spray drying favored for delicate substances and drum drying suited for thick, sticky feedstocks.

Choosing the Right Dryer for Your Application

Selecting the right dryer for your application depends on factors such as product moisture content, heat sensitivity, and particle size requirements. Drum dryers offer efficient drying for viscous liquids and produce flakes with relatively low thermal stress, making them ideal for heat-sensitive materials. Spray dryers excel in drying heat-sensitive liquids into fine powders quickly, ensuring consistent particle size distribution for products requiring high purity and uniformity.

Drum dryer vs spray dryer Infographic

libmatt.com

libmatt.com