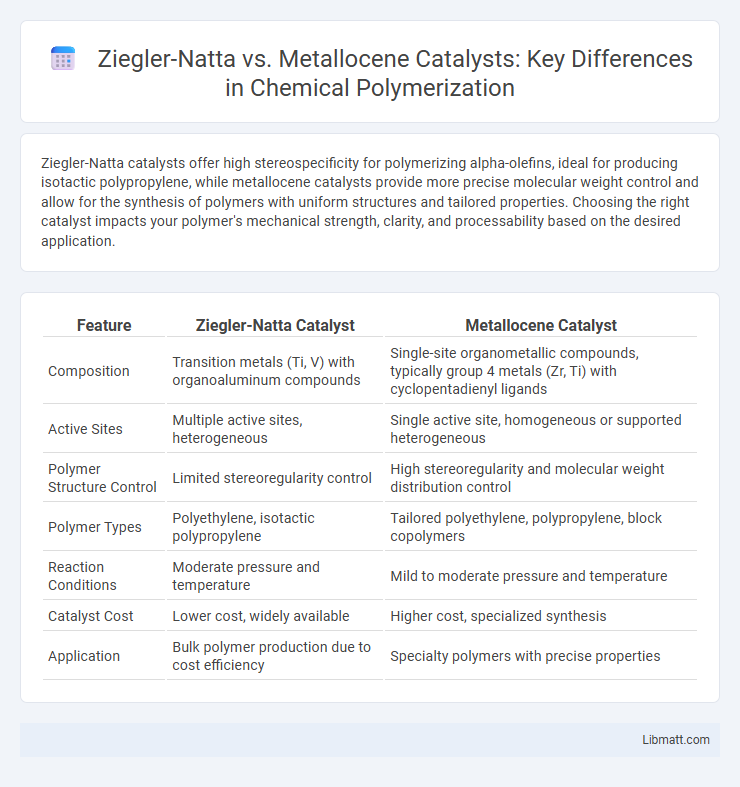

Ziegler-Natta catalysts offer high stereospecificity for polymerizing alpha-olefins, ideal for producing isotactic polypropylene, while metallocene catalysts provide more precise molecular weight control and allow for the synthesis of polymers with uniform structures and tailored properties. Choosing the right catalyst impacts your polymer's mechanical strength, clarity, and processability based on the desired application.

Table of Comparison

| Feature | Ziegler-Natta Catalyst | Metallocene Catalyst |

|---|---|---|

| Composition | Transition metals (Ti, V) with organoaluminum compounds | Single-site organometallic compounds, typically group 4 metals (Zr, Ti) with cyclopentadienyl ligands |

| Active Sites | Multiple active sites, heterogeneous | Single active site, homogeneous or supported heterogeneous |

| Polymer Structure Control | Limited stereoregularity control | High stereoregularity and molecular weight distribution control |

| Polymer Types | Polyethylene, isotactic polypropylene | Tailored polyethylene, polypropylene, block copolymers |

| Reaction Conditions | Moderate pressure and temperature | Mild to moderate pressure and temperature |

| Catalyst Cost | Lower cost, widely available | Higher cost, specialized synthesis |

| Application | Bulk polymer production due to cost efficiency | Specialty polymers with precise properties |

Introduction to Polyolefin Catalysts

Ziegler-Natta catalysts consist of transition metal compounds combined with organoaluminum cocatalysts, primarily used to polymerize olefins into polyolefins such as polyethylene and polypropylene with stereoregularity control. Metallocene catalysts, a subclass of single-site catalysts featuring a transition metal sandwiched between cyclopentadienyl ligands, enable precise molecular weight distribution and catalytic activity for tailored polyolefin properties. The choice between Ziegler-Natta and metallocene catalysts influences polymer microstructure, tacticity, and application performance, making catalyst selection critical in advanced polyolefin manufacturing.

Overview of Ziegler–Natta Catalysts

Ziegler-Natta catalysts are heterogeneous catalysts primarily composed of transition metal compounds such as titanium chlorides combined with organoaluminum co-catalysts. They revolutionized polymer chemistry by enabling the stereospecific polymerization of olefins like ethylene and propylene, producing polymers with controlled molecular weight and tacticity. Your understanding of polymer synthesis benefits from recognizing that Ziegler-Natta catalysts remain dominant in the production of polypropylene and polyethylene, thanks to their cost-effectiveness and high activity.

Overview of Metallocene Catalysts

Metallocene catalysts are organometallic compounds containing a transition metal sandwiched between cyclopentadienyl rings, offering precise control over polymer structure and stereochemistry. These catalysts enable the production of polyolefins with uniform molecular weight distribution and tailored properties such as enhanced clarity, strength, and flexibility. Compared to traditional Ziegler-Natta catalysts, metallocene catalysts provide improved activity, selectivity, and versatility in polymerization processes.

Structural Differences: Ziegler–Natta vs Metallocene

Ziegler-Natta catalysts consist of heterogeneous titanium chloride compounds supported on magnesium chloride with multiple active sites, enabling polymerization of olefins into isotactic or syndiotactic polymers. Metallocene catalysts feature homogeneous sandwich-like structures with a transition metal atom (typically group 4 metals like zirconium or titanium) bound between two cyclopentadienyl ligands, providing precise control over polymer stereochemistry and molecular weight distribution. The structural contrast between the multi-site Ziegler-Natta and the single-site metallocene catalysts directly influences polymer architecture, activity, and product uniformity.

Mechanisms of Polymerization

Ziegler-Natta catalysts polymerize olefins through coordination-insertion mechanisms involving transition metals like titanium or zirconium bonded with alkyl aluminum cocatalysts, creating active sites for stereoregular polymer chain growth. Metallocene catalysts operate via a single-site mechanism characterized by a well-defined, symmetrical transition metal center, typically zirconium or hafnium, allowing precise control over polymer microstructure and molecular weight distribution. Both catalysts facilitate chain propagation through insertion of monomers into metal-carbon bonds, but metallocenes offer enhanced control over polymer architecture due to their uniform active sites.

Catalyst Performance and Activity

Ziegler-Natta catalysts offer high stereospecificity and excellent control over polymer structure, making them ideal for producing isotactic and syndiotactic polymers with high crystallinity. Metallocene catalysts provide superior catalytic activity and uniform active sites, resulting in polymers with narrow molecular weight distribution and precise microstructure control. You can achieve tailored polymer properties by selecting the appropriate catalyst based on desired performance and activity requirements.

Polymer Properties and Applications

Ziegler-Natta catalysts typically produce polymers with a broad molecular weight distribution and high crystallinity, making them ideal for applications like packaging films, pipes, and household goods due to their mechanical strength and chemical resistance. Metallocene catalysts enable precise control over polymer architecture, resulting in polymers with narrow molecular weight distribution, improved clarity, and enhanced impact resistance, suitable for specialty films, medical devices, and adhesives. Your choice between these catalysts will influence the polymer's performance characteristics and its suitability for specific industrial applications.

Advantages and Limitations

Ziegler-Natta catalysts offer excellent control over polymer stereochemistry, making them ideal for producing high-density polyethylene and isotactic polypropylene with cost efficiency and scalability. Metallocene catalysts provide superior uniformity in polymer structure, enabling precise control over molecular weight distribution and polymer architecture, which benefits applications requiring specialized materials. Your choice depends on balancing the cost-effectiveness and wide industrial use of Ziegler-Natta catalysts against the advanced tunability and higher expense associated with metallocene catalysts.

Industrial Relevance and Market Impact

Ziegler-Natta catalysts dominate the polyolefin industry due to their proven efficiency in producing high-density polyethylene (HDPE) and isotactic polypropylene with tailored polymer structures, driving global market growth. Metallocene catalysts offer superior control over polymer architecture and molecular weight distribution, enabling the production of specialty polymers with enhanced mechanical and optical properties, thus expanding applications in packaging and automotive sectors. The growing demand for advanced materials and sustainability is increasing metallocene catalyst adoption, but Ziegler-Natta catalysts remain essential for bulk polymer production because of their cost-effectiveness and scalability.

Future Trends in Catalyst Technology

Future trends in catalyst technology emphasize the development of hybrid systems combining Ziegler-Natta and metallocene catalysts to optimize polymer microstructure and improve catalytic efficiency. Advances in molecular engineering aim to enhance the stereospecificity and activity of metallocene catalysts while reducing the dependency on titanium-based Ziegler-Natta systems to achieve sustainable polyolefin production. Integration of machine learning and high-throughput experimentation accelerates catalyst design, enabling precise control over polymer properties and reducing environmental impact.

Ziegler–Natta catalyst vs metallocene catalyst Infographic

libmatt.com

libmatt.com