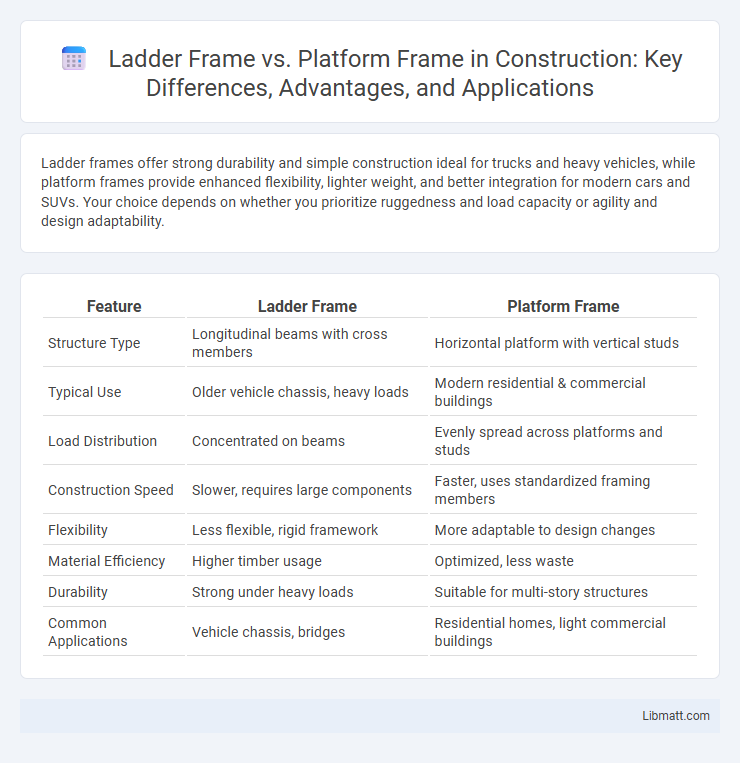

Ladder frames offer strong durability and simple construction ideal for trucks and heavy vehicles, while platform frames provide enhanced flexibility, lighter weight, and better integration for modern cars and SUVs. Your choice depends on whether you prioritize ruggedness and load capacity or agility and design adaptability.

Table of Comparison

| Feature | Ladder Frame | Platform Frame |

|---|---|---|

| Structure Type | Longitudinal beams with cross members | Horizontal platform with vertical studs |

| Typical Use | Older vehicle chassis, heavy loads | Modern residential & commercial buildings |

| Load Distribution | Concentrated on beams | Evenly spread across platforms and studs |

| Construction Speed | Slower, requires large components | Faster, uses standardized framing members |

| Flexibility | Less flexible, rigid framework | More adaptable to design changes |

| Material Efficiency | Higher timber usage | Optimized, less waste |

| Durability | Strong under heavy loads | Suitable for multi-story structures |

| Common Applications | Vehicle chassis, bridges | Residential homes, light commercial buildings |

Introduction to Ladder Frame and Platform Frame

Ladder frame and platform frame are two fundamental structural designs used in vehicle chassis construction. Ladder frame, characterized by its strong, rectangular design resembling a ladder, offers high durability and is commonly employed in trucks and off-road vehicles. Platform frame integrates a flat platform structure, providing enhanced rigidity and improved load distribution, making it ideal for modern passenger cars and lightweight vehicles.

Key Differences Between Ladder Frame and Platform Frame

Ladder frame construction features two longitudinal rails connected by several cross members, providing superior strength and durability often preferred in trucks and SUVs for heavy-duty use. Platform frame construction consists of separate body-on-frame design where the body is mounted on a flat frame platform, allowing for improved vehicle stability, safety, and ease of manufacturing in passenger cars. Key differences include ladder frames offering better flexibility for off-road and load-bearing capabilities, whereas platform frames emphasize lighter weight and enhanced torsional rigidity for better handling and fuel efficiency.

Historical Development of Automotive Frames

The ladder frame, originating in the early 20th century, was the dominant automotive frame design due to its simple, robust structure ideal for heavy-duty vehicles. The platform frame emerged later with advancements in unibody construction, offering improved rigidity and crash safety by integrating the frame and body into a single structure. Your choice between ladder and platform frames reflects a balance between traditional durability and modern engineering efficiency in vehicle design.

Structural Design and Engineering Principles

Ladder frame design features two longitudinal rails connected by multiple cross members, optimizing rigidity and load distribution for heavy-duty applications like trucks. Platform frame, or unibody construction, integrates the body and frame into a single structure, enhancing torsional stiffness and reducing vehicle weight for improved fuel efficiency and handling. Your choice between ladder frame and platform frame affects vehicle durability, crash safety, and manufacturing complexity due to their distinct engineering principles.

Strength and Durability Comparison

Ladder frames provide superior strength and durability due to their robust, continuous beam design, making them ideal for heavy-duty vehicles and off-road use. Platform frames, constructed with a flat, modular design, offer greater flexibility but generally less resistance to torsion and impact stresses. Your choice between these frames should consider the specific strength and durability requirements of your vehicle's intended use.

Performance in Various Vehicle Types

Ladder frames excel in heavy-duty vehicles like trucks and SUVs due to their high strength and durability, providing excellent load-bearing capacity and off-road performance. Platform frames are favored in passenger cars and electric vehicles for their lightweight design, improved fuel efficiency, and enhanced handling characteristics. Your choice depends on whether you prioritize ruggedness and towing capacity or lightweight agility and ride comfort.

Impact on Ride Quality and Handling

Ladder frames, known for their rigidity and durability, often result in a stiffer ride with less absorption of road vibrations, affecting overall ride comfort and handling precision. Platform frames, being lighter and more flexible, typically enhance ride quality by better absorbing shocks and improving vehicle agility and responsiveness. Your choice between these frames can significantly influence driving dynamics, with ladder frames favoring durability and platform frames prioritizing smoother handling.

Manufacturing Costs and Complexity

Ladder frame construction typically incurs higher manufacturing costs due to its heavy steel components and labor-intensive assembly, making it complex but durable for heavy-duty applications. Platform frame offers lower manufacturing expenses with its standardized, lighter wood or steel elements and simplified assembly process, reducing labor and material costs significantly. The choice between ladder and platform frames impacts overall project budgets, with platform framing favored in residential builds for cost efficiency and ladder frames preferred in commercial or automotive sectors for strength.

Popular Applications in Modern Vehicles

Ladder frames remain popular in trucks, SUVs, and off-road vehicles due to their robustness and ability to handle heavy loads. Platform frames are widely used in passenger cars and crossover vehicles for their lighter weight and improved fuel efficiency. Modern vehicle design increasingly favors platform frames for urban and highway driving, while ladder frames dominate in commercial and rugged terrain applications.

Future Trends in Vehicle Frame Technology

Ladder frames, known for their durability in heavy-duty vehicles, are gradually being supplemented by platform frames that offer enhanced rigidity and weight reduction, aligning with the automotive industry's shift towards lightweight and fuel-efficient designs. Future trends emphasize the integration of advanced materials like carbon fiber composites and aluminum alloys, significantly improving crash safety and performance in both frame types. Your choice in vehicle frame technology will increasingly reflect innovations supporting electric and autonomous vehicles, where structural adaptability and energy absorption become critical.

Ladder frame vs Platform frame Infographic

libmatt.com

libmatt.com