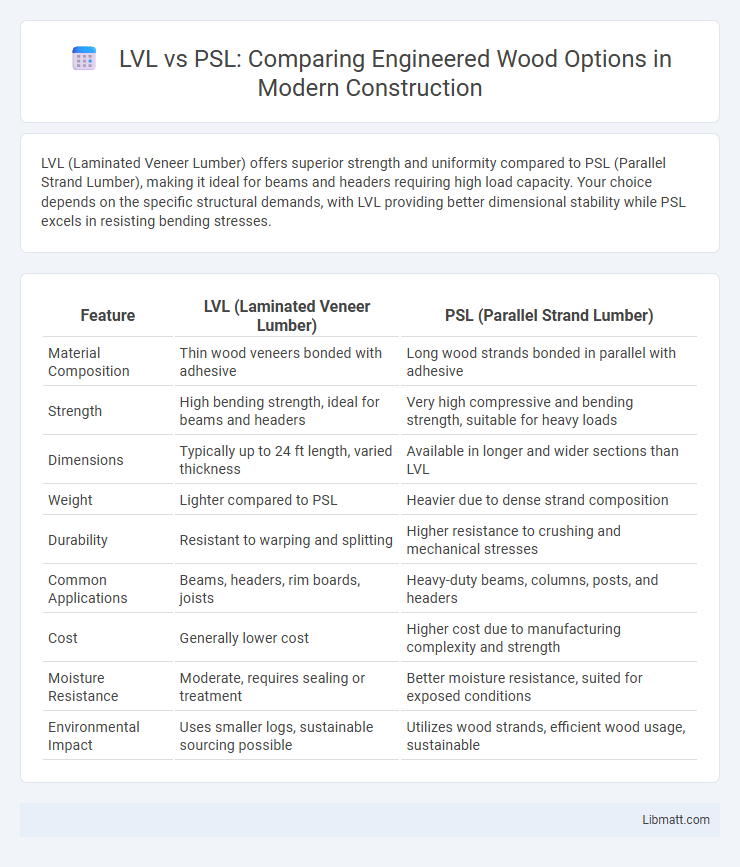

LVL (Laminated Veneer Lumber) offers superior strength and uniformity compared to PSL (Parallel Strand Lumber), making it ideal for beams and headers requiring high load capacity. Your choice depends on the specific structural demands, with LVL providing better dimensional stability while PSL excels in resisting bending stresses.

Table of Comparison

| Feature | LVL (Laminated Veneer Lumber) | PSL (Parallel Strand Lumber) |

|---|---|---|

| Material Composition | Thin wood veneers bonded with adhesive | Long wood strands bonded in parallel with adhesive |

| Strength | High bending strength, ideal for beams and headers | Very high compressive and bending strength, suitable for heavy loads |

| Dimensions | Typically up to 24 ft length, varied thickness | Available in longer and wider sections than LVL |

| Weight | Lighter compared to PSL | Heavier due to dense strand composition |

| Durability | Resistant to warping and splitting | Higher resistance to crushing and mechanical stresses |

| Common Applications | Beams, headers, rim boards, joists | Heavy-duty beams, columns, posts, and headers |

| Cost | Generally lower cost | Higher cost due to manufacturing complexity and strength |

| Moisture Resistance | Moderate, requires sealing or treatment | Better moisture resistance, suited for exposed conditions |

| Environmental Impact | Uses smaller logs, sustainable sourcing possible | Utilizes wood strands, efficient wood usage, sustainable |

Introduction to Engineered Wood: LVL and PSL

Engineered wood products like Laminated Veneer Lumber (LVL) and Parallel Strand Lumber (PSL) offer enhanced strength and dimensional stability compared to traditional solid wood. LVL is created by bonding thin wood veneers under heat and pressure, resulting in a uniform, high-strength beam ideal for headers and beams. PSL, produced by gluing long wood strands parallel to each other, provides superior load-bearing capacity, making it suitable for columns and heavy structural applications.

What is LVL? Definition and Key Properties

LVL (Laminated Veneer Lumber) is an engineered wood product made by bonding thin wood veneers with adhesives under heat and pressure, creating a strong and stable structural material. Key properties of LVL include high strength-to-weight ratio, uniformity, resistance to warping and twisting, and excellent dimensional stability due to its layered construction. LVL is widely used in beams, headers, and rim boards where consistent load-bearing performance is critical in construction.

What is PSL? Definition and Key Properties

Parallel Strand Lumber (PSL) is a high-strength engineered wood product made by bonding long, thin wood strands with adhesive under heat and pressure. Known for its exceptional load-bearing capacity, PSL offers increased dimensional stability, uniform strength, and resistance to warping compared to traditional lumber. If you require reliable structural support in beams or headers, PSL provides superior performance in demanding construction applications.

Manufacturing Processes: LVL vs PSL

LVL (Laminated Veneer Lumber) is manufactured by bonding thin wood veneers with adhesive under heat and pressure, creating strong, consistent layers oriented in the same direction for enhanced strength. PSL (Parallel Strand Lumber) is made by gluing together long, thin wood strands aligned parallel to each other, resulting in a dense, high-strength composite material ideal for structural applications. Your choice between LVL and PSL depends on the specific load requirements and dimensions needed in your construction project, as each engineered wood product offers unique manufacturing benefits.

Strength and Structural Performance Comparison

LVL (Laminated Veneer Lumber) offers superior tensile strength and dimensional stability due to its thin, parallel wood veneers bonded with adhesives, making it ideal for long-span applications. PSL (Parallel Strand Lumber) provides exceptional compressive strength and stiffness, utilizing long wood strands aligned longitudinally and bonded to deliver enhanced load-bearing capacity in columns and beams. Both engineered woods outperform traditional lumber, but LVL excels in bending performance while PSL is preferred for heavy structural support.

Common Applications: Where LVL Outshines PSL

LVL (Laminated Veneer Lumber) is favored in applications requiring long, straight structural elements such as beams, headers, and rim boards due to its uniform strength and dimensional stability. LVL's ability to resist warping and bowing makes it ideal for floor joists and roof rafters where precise alignment is critical. If you're looking for engineered wood with consistent quality for load-bearing frameworks, LVL outshines PSL (Parallel Strand Lumber) in situations demanding straightness and reliability.

Where PSL Excels Over LVL

Parallel Strand Lumber (PSL) excels over Laminated Veneer Lumber (LVL) in applications requiring exceptional compressive strength and load-bearing capacity, making it ideal for heavy structural beams and columns. Its dense, uniform composition enhances durability and resistance to warping, outperforming LVL in long-span performance without intermediate supports. If your project demands reliable, high-strength engineered wood for critical load paths, PSL offers superior structural integrity and stability.

Cost Differences Between LVL and PSL

LVL (Laminated Veneer Lumber) generally costs less than PSL (Parallel Strand Lumber) due to differences in raw material processing and manufacturing complexity. PSL pricing tends to be higher because it requires longer strands of wood and more intricate layering techniques, resulting in enhanced strength characteristics. Cost variability for both LVL and PSL depends on structural size, grade, and regional market conditions.

Durability and Environmental Considerations

LVL (Laminated Veneer Lumber) exhibits superior durability due to its cross-laminated veneer construction, which resists warping, splitting, and moisture damage better than PSL (Parallel Strand Lumber). PSL, made from parallel wood strands bonded with adhesive, is highly dense and strong but may require more treatment to withstand environmental factors over time. You should consider that LVL often has a lower environmental impact due to efficient use of wood veneers and sustainable forestry practices, while PSL's manufacturing process can involve higher energy consumption and adhesives with greater environmental footprints.

Choosing Between LVL and PSL: Decision Factors

Choosing between LVL (Laminated Veneer Lumber) and PSL (Parallel Strand Lumber) depends on load-bearing requirements, dimensional stability, and cost-effectiveness for your construction project. LVL offers superior strength in bending and is commonly used for beams and headers, while PSL provides higher compressive strength ideal for posts and columns. Understanding your specific structural needs and budget constraints ensures optimal material selection for safety and longevity.

LVL vs PSL (engineered wood) Infographic

libmatt.com

libmatt.com