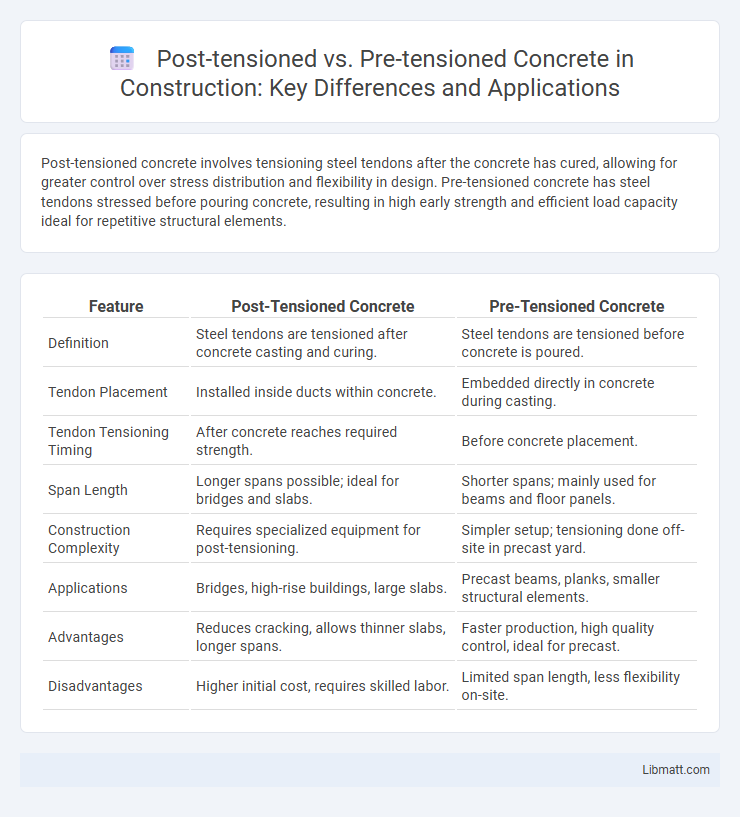

Post-tensioned concrete involves tensioning steel tendons after the concrete has cured, allowing for greater control over stress distribution and flexibility in design. Pre-tensioned concrete has steel tendons stressed before pouring concrete, resulting in high early strength and efficient load capacity ideal for repetitive structural elements.

Table of Comparison

| Feature | Post-Tensioned Concrete | Pre-Tensioned Concrete |

|---|---|---|

| Definition | Steel tendons are tensioned after concrete casting and curing. | Steel tendons are tensioned before concrete is poured. |

| Tendon Placement | Installed inside ducts within concrete. | Embedded directly in concrete during casting. |

| Tendon Tensioning Timing | After concrete reaches required strength. | Before concrete placement. |

| Span Length | Longer spans possible; ideal for bridges and slabs. | Shorter spans; mainly used for beams and floor panels. |

| Construction Complexity | Requires specialized equipment for post-tensioning. | Simpler setup; tensioning done off-site in precast yard. |

| Applications | Bridges, high-rise buildings, large slabs. | Precast beams, planks, smaller structural elements. |

| Advantages | Reduces cracking, allows thinner slabs, longer spans. | Faster production, high quality control, ideal for precast. |

| Disadvantages | Higher initial cost, requires skilled labor. | Limited span length, less flexibility on-site. |

Introduction to Prestressed Concrete

Prestressed concrete enhances structural performance by applying internal stresses to counteract tensile forces, increasing durability and load capacity. Post-tensioned concrete involves tensioning steel tendons after the concrete has hardened, allowing for longer spans and more flexible design. Pre-tensioned concrete uses steel tendons tensioned before casting, resulting in efficient mass production for elements like beams and slabs.

Overview of Post-Tensioned Concrete

Post-tensioned concrete involves placing steel tendons inside ducts cast within the concrete, which are tensioned after the concrete hardens to enhance structural capacity and reduce cracking. This method allows for longer spans and thinner slabs compared to traditional reinforced concrete by applying compressive force that counteracts tensile stresses during service. You can benefit from its increased durability, design flexibility, and improved load distribution in applications like bridges, parking structures, and high-rise buildings.

Overview of Pre-Tensioned Concrete

Pre-tensioned concrete involves casting concrete around steel tendons that are tensioned before the concrete is poured, creating a strong bond as the concrete cures. This technique enhances the structural capacity and durability of precast elements, making it ideal for beams, slabs, and railway sleepers. The pre-tensioning process effectively reduces tensile stresses and controls cracking, resulting in improved load-bearing performance and longevity.

Key Differences Between Post-Tensioning and Pre-Tensioning

Post-tensioned concrete involves stressing tendons after the concrete has cured, allowing for greater flexibility and longer spans with reduced cracking. Pre-tensioned concrete requires tensioning steel tendons before concrete is poured, ensuring immediate bonding for high strength and durability in repetitive, mass-produced elements. Understanding these key differences helps you select the appropriate method based on structural requirements and construction timelines.

Advantages of Post-Tensioned Concrete

Post-tensioned concrete offers enhanced structural efficiency by allowing longer spans and thinner slabs, which reduces overall material usage and construction costs. It provides superior crack control and increased load-bearing capacity due to the active tension applied after concrete curing. This method improves design flexibility, enabling the construction of complex architectural forms and faster construction schedules compared to pre-tensioned concrete.

Advantages of Pre-Tensioned Concrete

Pre-tensioned concrete offers superior quality control as the tendons are tensioned before the concrete is cast, ensuring consistent strength and durability. This method allows for faster production and early removal from molds, reducing construction time and costs. Your project benefits from high tensile strength and minimal cracking, making pre-tensioned concrete ideal for repetitive elements like bridges and slabs.

Common Applications of Post-Tensioned Concrete

Post-tensioned concrete is widely used in commercial building floors, bridges, parking structures, and long-span beams due to its ability to handle high stress and reduce material usage. It is ideal for complex architectural designs requiring thinner slabs, longer spans, and minimal joints. Infrastructure projects such as highways and airport runways also benefit from post-tensioned concrete's enhanced durability and load-bearing capacity.

Common Applications of Pre-Tensioned Concrete

Pre-tensioned concrete is commonly used in precast components such as bridge beams, railway sleepers, parking garage slabs, and building floor systems due to its high structural efficiency and durability. These elements benefit from the controlled factory environment where tendons are tensioned before casting, ensuring consistent pretensioning and minimizing cracking. Pre-tensioned concrete is ideal for mass-produced, repetitive structural elements requiring high tensile strength and reduced maintenance.

Cost Considerations: Post-Tensioned vs Pre-Tensioned

Post-tensioned concrete typically incurs higher initial installation costs due to specialized labor and materials, but its design flexibility often reduces overall project expenses by minimizing slab thickness and materials. Pre-tensioned concrete offers lower fabrication costs with mass-produced elements but may lead to higher transportation and installation expenses for complex or site-specific applications. Understanding your project's scale and design requirements helps determine which method provides the best cost efficiency.

Choosing the Right Method for Your Project

Selecting between post-tensioned and pre-tensioned concrete depends on project requirements such as span length, load conditions, and site constraints. Post-tensioned concrete offers greater flexibility and is ideal for longer spans and on-site tensioning, while pre-tensioned concrete suits repetitive, shorter spans with factory-controlled quality. Evaluating factors like construction speed, material efficiency, and structural performance ensures the optimal method for durability and cost-effectiveness.

Post-tensioned vs pre-tensioned concrete Infographic

libmatt.com

libmatt.com