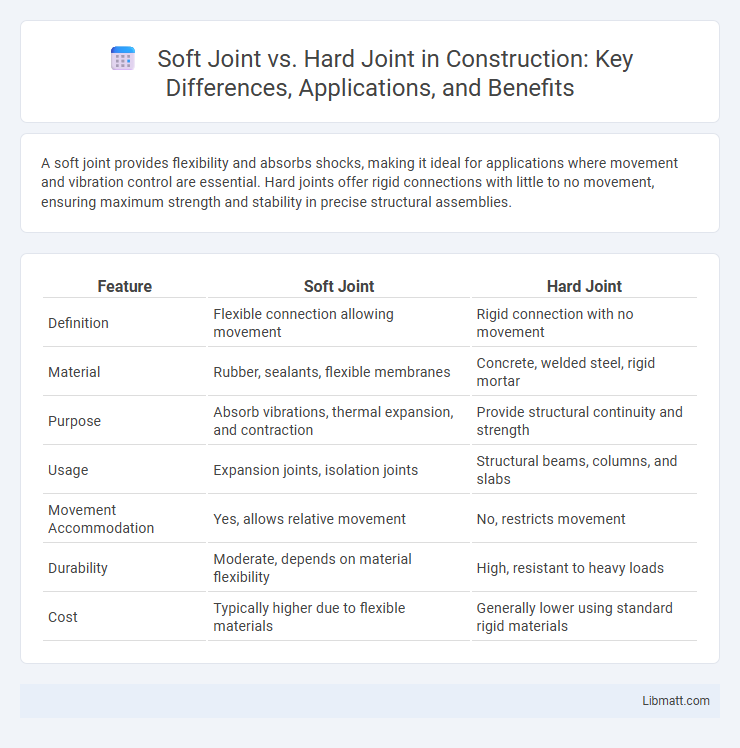

A soft joint provides flexibility and absorbs shocks, making it ideal for applications where movement and vibration control are essential. Hard joints offer rigid connections with little to no movement, ensuring maximum strength and stability in precise structural assemblies.

Table of Comparison

| Feature | Soft Joint | Hard Joint |

|---|---|---|

| Definition | Flexible connection allowing movement | Rigid connection with no movement |

| Material | Rubber, sealants, flexible membranes | Concrete, welded steel, rigid mortar |

| Purpose | Absorb vibrations, thermal expansion, and contraction | Provide structural continuity and strength |

| Usage | Expansion joints, isolation joints | Structural beams, columns, and slabs |

| Movement Accommodation | Yes, allows relative movement | No, restricts movement |

| Durability | Moderate, depends on material flexibility | High, resistant to heavy loads |

| Cost | Typically higher due to flexible materials | Generally lower using standard rigid materials |

Introduction to Soft Joint and Hard Joint Concepts

Soft joints provide flexibility and movement in structures by allowing controlled deformation, typically used in architectural designs to absorb stress and prevent cracking. Hard joints create rigid connections that restrict movement, offering strong support and stability ideal for load-bearing elements. Understanding the differences between soft and hard joints helps your construction project balance durability with necessary flexibility.

Defining Soft Joint: Characteristics and Applications

Soft joints are flexible connections designed to absorb movement and vibrations between structural elements, enhancing durability and comfort in buildings and machinery. Characterized by materials like rubber, foam, or flexible polymers, soft joints accommodate thermal expansion, seismic activity, and dynamic loads. You can find these joints commonly applied in automotive suspension systems, building expansion joints, and electronic device housings to prevent damage from stress and movement.

Understanding Hard Joint: Key Features and Use Cases

Hard joints provide rigid connections between components, ensuring structural stability and minimal movement, making them ideal for load-bearing applications like building frameworks and machinery assembly. These joints, such as welded, bolted, or riveted connections, offer high strength and resistance to shear and tensile forces. Their key features include permanence, durability, and precise alignment, crucial in environments demanding safety and long-term reliability.

Mechanical Behavior: Load Distribution and Absorption

Soft joints exhibit superior load distribution and absorption due to their inherent flexibility, allowing them to deform under stress and reduce peak forces on connected components. Hard joints, characterized by rigidity, transfer loads more directly and efficiently but concentrate stresses at the joint interface, increasing the risk of material fatigue or failure. The mechanical behavior of soft joints enhances vibration damping and shock absorption, while hard joints provide greater stiffness and dimensional stability under load.

Performance Differences: Torque, Clamping Force, and Stability

Soft joints typically exhibit lower torque transmission and reduced clamping force compared to hard joints, impacting overall mechanical performance. Hard joints provide higher stability and consistent torque capacity due to their rigid connection, ensuring secure clamping force and minimizing vibration. Understanding these performance differences helps you optimize joint selection for applications requiring precise load management and robust stability.

Material Selection for Soft and Hard Joints

Material selection for soft joints typically involves flexible, elastomeric substances like rubber, silicone, or polyurethane, which accommodate movement and absorb vibrations. Hard joints commonly use rigid materials such as metals (steel, aluminum) or hard plastics that provide strong structural support and resist deformation under load. Your choice between soft and hard joint materials depends on the application's requirements for flexibility, durability, and load-bearing capacity.

Joint Design Considerations and Best Practices

Soft joint design prioritizes flexibility and tolerance to accommodate thermal expansion, vibrations, and misalignments, making it ideal for dynamic or variable load applications. Hard joints require precise alignment and rigidity, ensuring minimal movement for high-strength or load-bearing structures where stability is critical. Best practices include selecting appropriate materials, considering load conditions, and evaluating environmental factors to optimize joint durability and performance.

Common Industries and Examples for Each Joint Type

Soft joints, commonly used in the electronics and automotive industries, offer flexibility and vibration absorption ideal for wiring harnesses and printed circuit boards. Hard joints, prevalent in construction and aerospace sectors, provide rigid, permanent connections essential for structural steel frameworks and aircraft fuselage assemblies. Examples include soldered connections in consumer electronics for soft joints and welded steel beams in skyscraper construction for hard joints.

Troubleshooting Joint Failure: Causes and Solutions

Troubleshooting joint failure involves identifying causes such as improper load distribution, material fatigue, and inadequate fastening in both soft joints and hard joints. Soft joint failures often stem from excessive deformation or insufficient rigidity, while hard joint failures typically arise from brittle fractures or loosening under vibration. You can address these issues by selecting appropriate materials, optimizing joint design for load conditions, and ensuring proper installation techniques.

Choosing Between Soft Joint and Hard Joint for Optimal Performance

Choosing between soft joint and hard joint hinges on the specific application requirements for flexibility versus rigidity. Soft joints provide better shock absorption and accommodate slight misalignments, ideal for dynamic or delicate assemblies. Hard joints offer superior strength and stability, making them suitable for load-bearing structures where precision and durability are critical.

Soft joint vs Hard joint Infographic

libmatt.com

libmatt.com