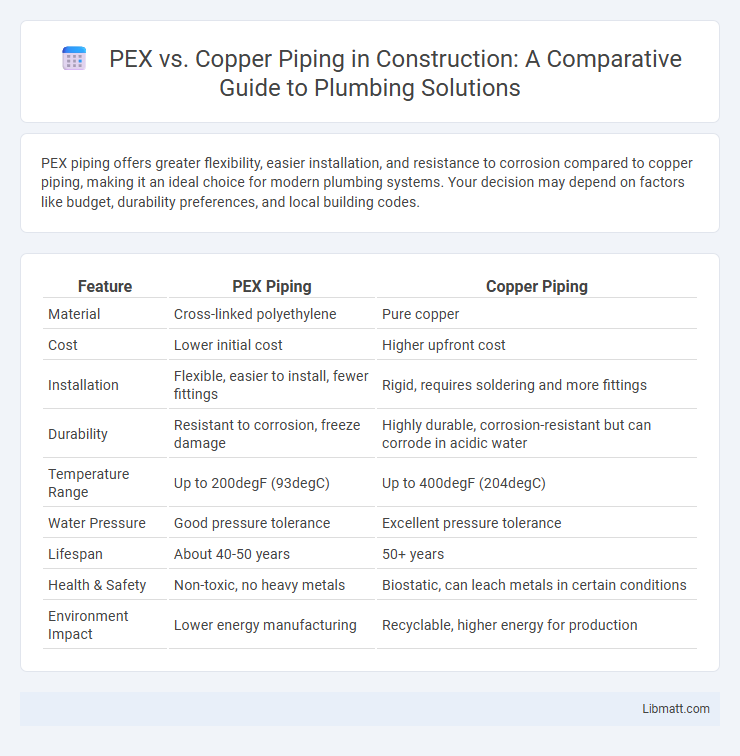

PEX piping offers greater flexibility, easier installation, and resistance to corrosion compared to copper piping, making it an ideal choice for modern plumbing systems. Your decision may depend on factors like budget, durability preferences, and local building codes.

Table of Comparison

| Feature | PEX Piping | Copper Piping |

|---|---|---|

| Material | Cross-linked polyethylene | Pure copper |

| Cost | Lower initial cost | Higher upfront cost |

| Installation | Flexible, easier to install, fewer fittings | Rigid, requires soldering and more fittings |

| Durability | Resistant to corrosion, freeze damage | Highly durable, corrosion-resistant but can corrode in acidic water |

| Temperature Range | Up to 200degF (93degC) | Up to 400degF (204degC) |

| Water Pressure | Good pressure tolerance | Excellent pressure tolerance |

| Lifespan | About 40-50 years | 50+ years |

| Health & Safety | Non-toxic, no heavy metals | Biostatic, can leach metals in certain conditions |

| Environment Impact | Lower energy manufacturing | Recyclable, higher energy for production |

Introduction to PEX and Copper Piping

PEX piping, made from cross-linked polyethylene, offers flexibility, corrosion resistance, and easier installation compared to copper piping, which is a traditional metal known for its durability, heat tolerance, and antimicrobial properties. Copper piping has been widely used for decades in plumbing systems due to its strength and long lifespan, but PEX is gaining popularity for its cost-effectiveness and resistance to freezing temperatures. Understanding the differences between PEX and copper can help you choose the best option for your home's plumbing needs and budget.

Material Composition and Structure

PEX (cross-linked polyethylene) piping consists of flexible, synthetic polymers formed through a cross-linking process, enhancing durability and resistance to temperature variations. Copper piping is made from a naturally corrosion-resistant metal alloy known for its rigidity, thermal conductivity, and longevity in plumbing applications. The structural flexibility of PEX allows easier installation with fewer fittings, whereas copper's solid metallic composition provides superior strength and reliability under high pressure.

Installation Process Comparison

PEX piping offers a quicker and more flexible installation process compared to copper due to its lightweight, bendable nature, and fewer connection fittings needed. Copper installation requires soldering or specialized fittings, which demands more time, skill, and the use of open flames or expensive tools. PEX's ability to snake through walls and around corners without jointing reduces labor costs and installation time significantly.

Durability and Lifespan

PEX piping offers superior flexibility and resistance to corrosion, scaling, and chlorine compared to copper, contributing to a lifespan of 40 to 50 years. Copper piping is highly durable with natural antimicrobial properties and typically lasts 50 to 70 years but is prone to corrosion and pinhole leaks in certain water conditions. Both materials provide reliable durability, though PEX's resistance to freeze damage and ease of installation often enhance its practical longevity in various plumbing systems.

Cost Analysis: PEX vs Copper

PEX piping typically offers a lower upfront cost compared to copper, with material prices often 30-50% cheaper, making it a budget-friendly option for your plumbing needs. Copper, while more expensive, provides higher durability and resale value, which can offset initial costs over time. Labor costs for installing PEX are generally reduced due to its flexibility and easier handling, further enhancing overall cost savings.

Performance in Extreme Temperatures

PEX piping offers superior flexibility and resistance to freezing temperatures compared to copper, reducing the risk of bursts and leaks in cold climates. Copper excels in high-temperature environments, maintaining structural integrity and withstanding heat up to 400degF without deformation. Both materials perform reliably, but PEX is favored for freeze-prone areas while copper is preferred for hot water systems and fire-resistant applications.

Corrosion and Chemical Resistance

PEX piping offers superior corrosion and chemical resistance compared to copper, as it does not rust or suffer from mineral buildup over time. Copper pipes can corrode when exposed to acidic or alkaline water, leading to pinhole leaks and reduced lifespan. PEX maintains durability in environments with aggressive water chemistry, making it ideal for long-term plumbing reliability.

Water Quality and Taste Impact

PEX piping resists corrosion and scale buildup, which helps maintain clean water quality and prevents metallic taste often associated with copper pipes. Copper can leach trace amounts of metal into water, potentially altering taste, especially in acidic or soft water conditions. Your choice of piping material directly influences water purity and flavor, with PEX offering a neutral impact on taste.

Environmental Impact and Sustainability

PEX piping demonstrates a lower environmental impact compared to copper due to its reduced energy consumption during production and lower greenhouse gas emissions. Copper extraction and manufacturing involve significant mining activities, leading to habitat disruption and higher carbon footprints. The recyclability of copper gives it a sustainability advantage, but PEX's longer lifespan and resistance to corrosion contribute to reduced material waste and resource use over time.

Common Applications and Best Uses

PEX piping excels in residential plumbing for hot and cold water distribution due to its flexibility and resistance to corrosion, making it ideal for retrofit projects and areas with complex layouts. Copper piping is preferred in commercial buildings and high-temperature applications because of its durability, antimicrobial properties, and ability to withstand extreme conditions. Your choice between PEX and copper will depend on factors like installation environment, durability requirements, and budget considerations.

PEX vs Copper piping Infographic

libmatt.com

libmatt.com