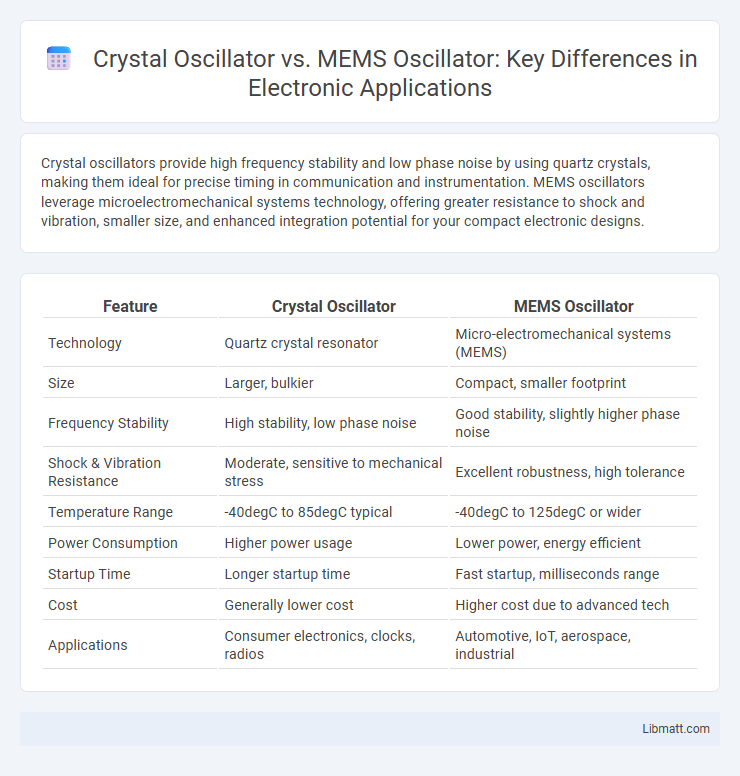

Crystal oscillators provide high frequency stability and low phase noise by using quartz crystals, making them ideal for precise timing in communication and instrumentation. MEMS oscillators leverage microelectromechanical systems technology, offering greater resistance to shock and vibration, smaller size, and enhanced integration potential for your compact electronic designs.

Table of Comparison

| Feature | Crystal Oscillator | MEMS Oscillator |

|---|---|---|

| Technology | Quartz crystal resonator | Micro-electromechanical systems (MEMS) |

| Size | Larger, bulkier | Compact, smaller footprint |

| Frequency Stability | High stability, low phase noise | Good stability, slightly higher phase noise |

| Shock & Vibration Resistance | Moderate, sensitive to mechanical stress | Excellent robustness, high tolerance |

| Temperature Range | -40degC to 85degC typical | -40degC to 125degC or wider |

| Power Consumption | Higher power usage | Lower power, energy efficient |

| Startup Time | Longer startup time | Fast startup, milliseconds range |

| Cost | Generally lower cost | Higher cost due to advanced tech |

| Applications | Consumer electronics, clocks, radios | Automotive, IoT, aerospace, industrial |

Introduction to Crystal and MEMS Oscillators

Crystal oscillators rely on quartz crystal vibrations to generate highly stable and accurate frequency signals essential for telecommunications, consumer electronics, and industrial applications. MEMS oscillators use microelectromechanical systems technology to produce frequency signals with improved shock resistance, smaller size, and greater integration flexibility compared to traditional crystals. Your choice depends on the need for precision and environmental robustness, with MEMS oscillators gaining popularity in compact, high-reliability systems.

Basic Operating Principles

Crystal oscillators operate by exploiting the piezoelectric effect in quartz crystals, where an electric field induces mechanical vibrations at a precise resonant frequency, creating a stable oscillation. MEMS oscillators use microelectromechanical systems technology, relying on tiny silicon-based mechanical resonators that vibrate electrically to produce an oscillation signal. Both provide frequency reference signals, but MEMS oscillators leverage semiconductor manufacturing for integration and durability advantages over traditional quartz crystals.

Key Differences Between Crystal and MEMS Oscillators

Crystal oscillators rely on quartz crystal's piezoelectric properties for frequency stability, while MEMS oscillators use microelectromechanical systems technology to achieve similar results with greater integration and smaller form factors. MEMS oscillators offer improved resistance to shock, vibration, and environmental variations compared to the more fragile crystal oscillators. Crystal oscillators typically provide superior long-term frequency stability and lower phase noise, whereas MEMS oscillators excel in size, power consumption, and manufacturability for modern electronics.

Frequency Stability and Accuracy Comparison

Crystal oscillators typically offer superior frequency stability and accuracy, maintaining variations within a few parts per million (ppm) over temperature changes due to their high-quality quartz resonators. MEMS oscillators provide competitive performance with frequency stability around +-10 ppm, benefiting from temperature compensation and calibration but generally fall short of the long-term accuracy of crystal oscillators. Both technologies are used in precision timing applications, though crystal oscillators remain the preferred choice when the highest frequency stability and accuracy are critical.

Size, Form Factor, and Integration

MEMS oscillators typically offer a smaller size and more compact form factor compared to traditional crystal oscillators, enabling easier integration into miniaturized electronic devices. Unlike quartz crystals, MEMS devices can be fabricated using semiconductor processes, allowing for greater integration with ICs and customizable package options. This results in improved scalability for modern applications requiring space-saving and highly integrated timing solutions.

Power Consumption and Efficiency

MEMS oscillators typically consume less power compared to traditional crystal oscillators, making them more efficient for battery-powered and portable applications. The low power consumption in MEMS devices is due to their micro-scale mechanical structures and integrated circuit design, which reduce energy loss. Crystal oscillators, while highly stable, generally require more power for operation, impacting efficiency in energy-sensitive environments.

Environmental Robustness and Reliability

Crystal oscillators offer high frequency stability but are susceptible to environmental factors such as shock, vibration, and temperature variations, which can affect their long-term reliability. MEMS oscillators provide superior environmental robustness due to their solid-state design, exhibiting greater resistance to mechanical stress and wide temperature ranges. Their enhanced durability makes MEMS oscillators more suitable for applications demanding high reliability in harsh or variable environmental conditions.

Cost and Supply Chain Considerations

Crystal oscillators generally offer lower initial costs due to established manufacturing processes but face longer lead times and supply chain volatility linked to raw quartz availability. MEMS oscillators provide more stable supply chains with wafer-based fabrication, reducing dependency on quartz and enabling faster lead times despite slightly higher unit prices. Your decision should weigh these factors alongside volume requirements and market fluctuations to optimize cost-effectiveness and reliability.

Applications and Use Cases

Crystal oscillators are commonly used in consumer electronics, telecommunications, and automotive systems due to their high frequency stability and low phase noise, making them ideal for applications like GPS receivers, radios, and microcontrollers. MEMS oscillators excel in harsh environments such as aerospace, industrial automation, and medical devices, where their resistance to shock, vibration, and temperature variations ensures reliable timing performance. Both technologies serve critical roles in clock generation and timing synchronization, with crystal oscillators favored for precision and MEMS oscillators preferred for robustness and integration flexibility.

Choosing the Right Oscillator for Your Project

Choosing the right oscillator for your project depends on factors like frequency stability, size, and environmental resilience. Crystal oscillators offer high frequency accuracy and low phase noise, making them ideal for precision applications, while MEMS oscillators provide better shock resistance, smaller form factor, and faster start-up times suitable for portable and rugged devices. Consider trade-offs in cost and temperature performance when selecting between quartz crystal oscillators and MEMS-based oscillators to meet your project's specific requirements.

Crystal oscillator vs MEMS oscillator Infographic

libmatt.com

libmatt.com