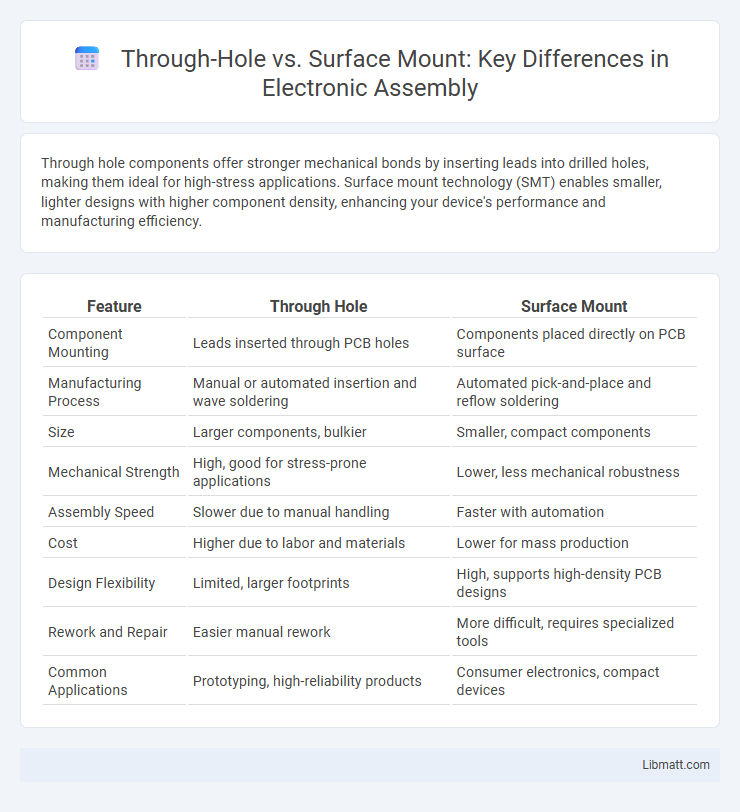

Through hole components offer stronger mechanical bonds by inserting leads into drilled holes, making them ideal for high-stress applications. Surface mount technology (SMT) enables smaller, lighter designs with higher component density, enhancing your device's performance and manufacturing efficiency.

Table of Comparison

| Feature | Through Hole | Surface Mount |

|---|---|---|

| Component Mounting | Leads inserted through PCB holes | Components placed directly on PCB surface |

| Manufacturing Process | Manual or automated insertion and wave soldering | Automated pick-and-place and reflow soldering |

| Size | Larger components, bulkier | Smaller, compact components |

| Mechanical Strength | High, good for stress-prone applications | Lower, less mechanical robustness |

| Assembly Speed | Slower due to manual handling | Faster with automation |

| Cost | Higher due to labor and materials | Lower for mass production |

| Design Flexibility | Limited, larger footprints | High, supports high-density PCB designs |

| Rework and Repair | Easier manual rework | More difficult, requires specialized tools |

| Common Applications | Prototyping, high-reliability products | Consumer electronics, compact devices |

Introduction to Through Hole and Surface Mount Technologies

Through hole technology involves inserting component leads into drilled holes on a printed circuit board (PCB) and soldering them on the opposite side, offering strong mechanical bonds ideal for components subject to mechanical stress. Surface mount technology (SMT) places components directly onto the surface of the PCB, enabling higher component density and automated assembly for faster production. Industry trends favor SMT due to miniaturization demands and cost efficiency, though through hole remains essential for connectors and components requiring durability.

Key Differences Between Through Hole and Surface Mount

Through hole and surface mount technologies differ primarily in their mounting techniques; through hole components have leads inserted into drilled holes on the PCB, while surface mount components are placed directly on the board's surface. Through hole mounting offers stronger mechanical bonds, suitable for high-stress environments, whereas surface mount technology (SMT) allows for higher component density and automated assembly. The electrical performance also varies, with surface mount components generally providing better high-frequency characteristics due to shorter lead lengths.

Historical Evolution of PCB Assembly Methods

Through hole technology dominated early PCB assembly due to its mechanical strength and ease of manual soldering, dating back to the 1960s. The advent of surface mount technology (SMT) in the 1980s revolutionized PCB design by enabling smaller component sizes, higher circuit density, and automated assembly processes. Your choice between through hole and surface mount reflects a balance between traditional durability and modern efficiency in electronic manufacturing.

Advantages of Through Hole Technology

Through Hole Technology offers superior mechanical strength due to components being soldered through the PCB, making it ideal for high-stress applications and heavy connectors. It enhances durability and reliability in environments subject to vibration or physical stress, commonly found in industrial and automotive electronics. The technology also facilitates easier prototyping and manual assembly, supporting repairability and rework.

Benefits of Surface Mount Technology

Surface Mount Technology (SMT) offers significant advantages, including higher component density on printed circuit boards (PCBs), enabling smaller and more complex designs. SMT enhances automated assembly processes, resulting in faster production rates and reduced labor costs. Moreover, SMT provides improved electrical performance due to shorter lead lengths, which minimizes inductance and signal distortion.

Limitations of Through Hole Technology

Through hole technology faces limitations such as larger component sizes, which restrict high-density circuit designs and increase PCB space requirements. It also results in longer manufacturing times and higher costs due to manual soldering or complex automated processes. Your designs may suffer reduced electrical performance and limited compatibility with modern miniaturized components compared to surface mount technology.

Challenges of Surface Mount Assembly

Surface mount assembly faces challenges such as the need for precise placement technology due to smaller component sizes, which increases equipment costs and maintenance requirements. Thermal management becomes critical as components are more densely packed, raising the risk of overheating during soldering processes. Additionally, inspection and repair of surface mount devices demand specialized tools and skills, complicating manufacturing and quality control efforts.

Applications Best Suited for Through Hole

Through hole components offer superior mechanical strength and are ideal for applications requiring durable and reliable connections, such as aerospace, military, and automotive electronics. These components excel in prototypes, high-power devices, and situations where components may face mechanical stress or high temperatures. You benefit from enhanced stability and easier manual assembly when using through hole technology in rugged or high-reliability environments.

Industries Favoring Surface Mount Solutions

Industries such as consumer electronics, automotive, and telecommunications predominantly favor surface mount technology (SMT) due to its ability to support miniaturized, high-density circuit designs. SMT components allow for faster assembly and improved electrical performance, making them ideal for mass production and complex modern devices. Your choice of surface mount solutions can enhance product reliability and manufacturing efficiency in these fast-paced sectors.

Choosing the Right Technology for Your Project

Choosing the right technology for your project involves evaluating factors like board space, assembly costs, and component durability. Through hole technology offers stronger mechanical bonds ideal for high-stress environments and prototyping, while surface mount devices provide higher component density and faster automated assembly suitable for mass production. Assessing project requirements such as electrical performance, thermal management, and production volume will guide the selection between through hole and surface mount technologies.

Through Hole vs Surface Mount Infographic

libmatt.com

libmatt.com