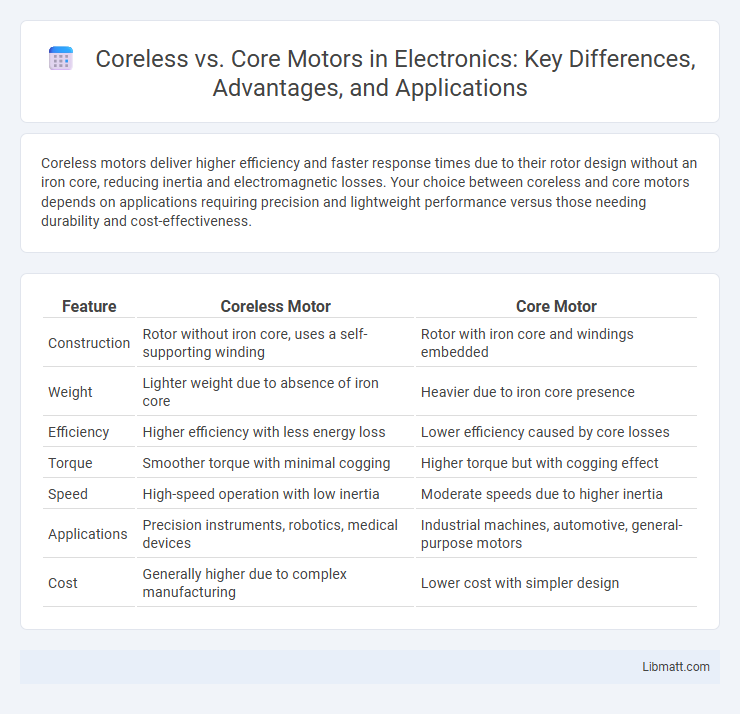

Coreless motors deliver higher efficiency and faster response times due to their rotor design without an iron core, reducing inertia and electromagnetic losses. Your choice between coreless and core motors depends on applications requiring precision and lightweight performance versus those needing durability and cost-effectiveness.

Table of Comparison

| Feature | Coreless Motor | Core Motor |

|---|---|---|

| Construction | Rotor without iron core, uses a self-supporting winding | Rotor with iron core and windings embedded |

| Weight | Lighter weight due to absence of iron core | Heavier due to iron core presence |

| Efficiency | Higher efficiency with less energy loss | Lower efficiency caused by core losses |

| Torque | Smoother torque with minimal cogging | Higher torque but with cogging effect |

| Speed | High-speed operation with low inertia | Moderate speeds due to higher inertia |

| Applications | Precision instruments, robotics, medical devices | Industrial machines, automotive, general-purpose motors |

| Cost | Generally higher due to complex manufacturing | Lower cost with simpler design |

Introduction to Coreless and Core Motors

Coreless motors feature a rotor with a hollow or ironless design that reduces weight and inertia, allowing for faster acceleration and higher efficiency compared to traditional core motors. Core motors utilize a solid iron core in the rotor, providing increased magnetic flux and torque but resulting in higher rotational inertia and potential cogging effects. These fundamental structural differences influence their applications, with coreless motors preferred in precision devices and core motors favored in high-torque, cost-sensitive projects.

Basic Construction Differences

Coreless motors feature a rotor made of a self-supporting winding without an iron core, reducing inertia and enabling faster acceleration. In contrast, core motors have a traditional iron-core rotor that provides magnetic flux but adds weight and rotational inertia. Your choice depends on whether lightweight efficiency or higher torque from the iron core better suits your application.

How Coreless Motors Work

Coreless motors operate by eliminating the traditional iron core from the rotor, resulting in a lightweight, low-inertia design that allows for rapid acceleration and high precision. The rotor consists of a self-supporting coil that rotates within a permanent magnet stator, reducing electromagnetic losses and improving efficiency. This design enhances your device's responsiveness and performance, especially in applications requiring quick speed changes and smooth operation.

How Core Motors Work

Core motors operate using a central iron core wrapped with coils of wire that generate a magnetic field when electric current flows through them. This magnetic field interacts with the magnets in the motor to produce rotational motion via electromagnetic force. The presence of the iron core increases the motor's magnetic flux density, enhancing torque and efficiency compared to coreless motors.

Performance Comparison: Efficiency and Speed

Coreless motors offer higher efficiency due to reduced iron losses and lower rotor inertia, enabling faster acceleration and smoother operation compared to traditional core motors. Core motors, while generally more robust and cost-effective, tend to have increased electromagnetic losses that diminish their efficiency at high speeds. Your choice between coreless and core motors should consider whether maximum speed and efficiency or durability and cost are the priority for your application.

Size and Weight Considerations

Coreless motors offer significant advantages in size and weight compared to core motors due to their unique design that eliminates the iron core, resulting in a lighter and more compact structure. This reduction in mass enhances efficiency and responsiveness, making coreless motors ideal for applications where minimizing weight and space is crucial, such as in drones and portable medical devices. Your choice between these motor types directly impacts the overall system design, especially in environments with strict size and weight constraints.

Heat Dissipation and Durability

Coreless motors excel in heat dissipation due to the absence of an iron core, allowing faster thermal transfer and reduced heat buildup during high-speed operations. Core motors, with their iron cores, tend to retain more heat, potentially leading to quicker wear and reduced durability under heavy loads. The enhanced heat management in coreless designs contributes to longer operational lifespan and greater reliability in demanding applications.

Application Areas for Each Motor Type

Coreless motors excel in applications requiring high precision and rapid acceleration, such as medical devices, robotics, and aerospace instruments due to their lightweight rotor and minimal inertia. Core motors are suited for heavy-duty industrial machinery, electric vehicles, and household appliances where durability and continuous power output are critical. Selection between coreless and core motors depends on specific performance needs, including torque, efficiency, and operational environment.

Cost and Maintenance Factors

Coreless motors generally have higher initial costs due to advanced manufacturing techniques and lightweight materials but offer lower maintenance expenses because they avoid iron core-related wear and reduce friction. Traditional core motors are typically more affordable upfront but may incur higher maintenance costs from core losses, such as iron losses and increased heat generation, leading to more frequent servicing. Evaluating coreless versus core motors requires balancing upfront investment against long-term maintenance efficiency, especially in precision applications where reliability matters.

Choosing the Right Motor for Your Needs

Coreless motors offer lightweight design, high acceleration, and minimal cogging, making them ideal for precision applications like drones and medical devices. Core motors provide greater torque and durability, suitable for heavy-duty tasks such as industrial machinery and electric vehicles. Selecting the right motor depends on balancing performance requirements, weight constraints, and application-specific demands.

Coreless vs Core Motor Infographic

libmatt.com

libmatt.com