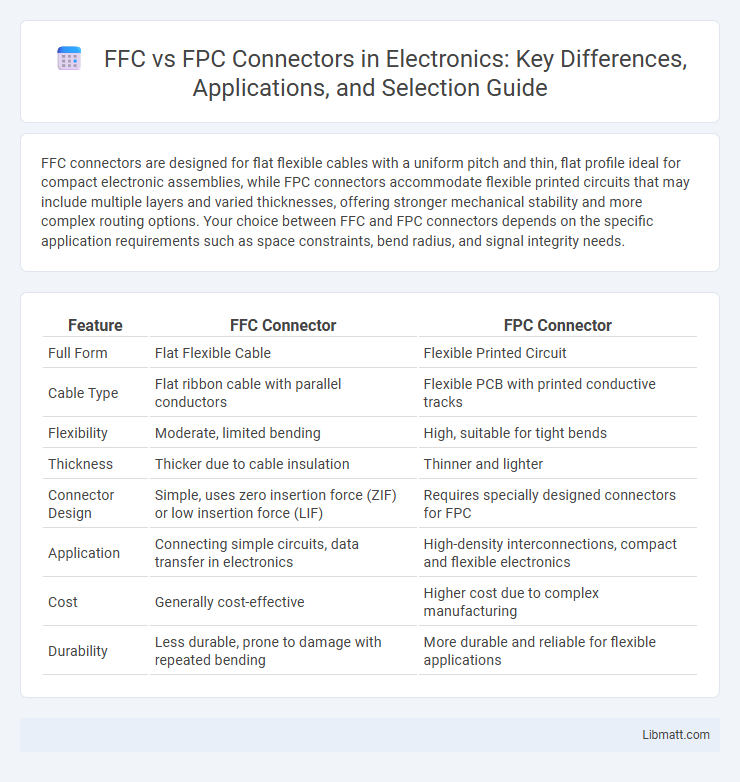

FFC connectors are designed for flat flexible cables with a uniform pitch and thin, flat profile ideal for compact electronic assemblies, while FPC connectors accommodate flexible printed circuits that may include multiple layers and varied thicknesses, offering stronger mechanical stability and more complex routing options. Your choice between FFC and FPC connectors depends on the specific application requirements such as space constraints, bend radius, and signal integrity needs.

Table of Comparison

| Feature | FFC Connector | FPC Connector |

|---|---|---|

| Full Form | Flat Flexible Cable | Flexible Printed Circuit |

| Cable Type | Flat ribbon cable with parallel conductors | Flexible PCB with printed conductive tracks |

| Flexibility | Moderate, limited bending | High, suitable for tight bends |

| Thickness | Thicker due to cable insulation | Thinner and lighter |

| Connector Design | Simple, uses zero insertion force (ZIF) or low insertion force (LIF) | Requires specially designed connectors for FPC |

| Application | Connecting simple circuits, data transfer in electronics | High-density interconnections, compact and flexible electronics |

| Cost | Generally cost-effective | Higher cost due to complex manufacturing |

| Durability | Less durable, prone to damage with repeated bending | More durable and reliable for flexible applications |

Introduction to FFC and FPC Connectors

FFC (Flat Flexible Cable) and FPC (Flexible Printed Circuit) connectors are essential components used to connect flexible cables to electronic devices. FFC connectors are designed specifically for flat flexible cables, featuring a simple structure that offers reliable connections in compact spaces. FPC connectors, on the other hand, accommodate flexible printed circuits, providing higher density connections and enhanced durability for intricate electronic assemblies.

Definition and Core Features of FFC Connectors

FFC (Flat Flexible Cable) connectors are compact, lightweight connectors designed to interface with flat flexible cables, characterized by their thin, flat ribbon-like structure. These connectors typically feature a zero insertion force (ZIF) or low insertion force (LIF) mechanism, ensuring secure connections without damaging delicate cable conductors. Your electronic designs benefit from FFC connectors' high-density contact arrangement and excellent signal integrity, making them ideal for tight spaces in consumer electronics and automotive applications.

Definition and Core Features of FPC Connectors

FPC connectors, or Flexible Printed Circuit connectors, are compact, lightweight electrical connectors designed to connect flexible printed circuit boards to rigid printed circuit boards or other components. They feature a low profile, high pin density, and reliable contact mechanisms that ensure stable electrical connections in compact electronic devices. Your choice of FPC connectors enables efficient signal transmission and space-saving design in applications like smartphones, cameras, and wearable technology.

Key Differences Between FFC and FPC Connectors

FFC connectors are designed specifically for flat flexible cables, featuring a simple ribbon-like structure that provides easy insertion and removal, while FPC connectors accommodate flat printed circuits with a more complex design supporting higher pin density and greater flexibility. The key differences include the physical structure, with FFC connectors using exposed conductive strips and FPC connectors utilizing flexible PCB material with integrated circuitry. Your choice depends on the application requirements for durability, signal integrity, and connection density.

Common Applications for FFC Connectors

FFC connectors are widely used in compact electronic devices such as laptops, printers, and smartphones due to their slim design and reliable signal transmission. These connectors enable flexible circuit connections in applications where space constraints and frequent movement demand durable and lightweight interconnect solutions. Your choice of FFC connectors ensures efficient assembly in consumer electronics, automotive dashboards, and industrial equipment.

Typical Uses for FPC Connectors

FPC connectors are widely used in compact electronic devices such as smartphones, laptops, and cameras due to their slim profile and flexible cable compatibility. These connectors facilitate high-density, space-saving connections between printed circuit boards, making them ideal for applications requiring lightweight and flexible interconnects. Common industries utilizing FPC connectors include consumer electronics, automotive instrumentation, and medical devices.

Advantages and Disadvantages of FFC Connectors

FFC connectors offer high-density connections with a compact design that saves space in electronic devices, enhancing your product's portability and flexibility. They provide excellent signal integrity and flexibility but can be vulnerable to damage from repeated bending or improper handling, which may impact durability. The ease of installation and cost-effectiveness are advantages, while limited mechanical strength and lower current capacity compared to FPC connectors represent the main disadvantages.

Pros and Cons of FPC Connectors

FPC connectors offer compact size and flexibility, making them ideal for applications with limited space and requiring high-density interconnections. They provide reliable electrical performance and ease of assembly, but their delicate construction can lead to higher susceptibility to damage compared to more robust options like FFC connectors. Cost efficiency in low-volume production and the ability to accommodate complex bending in tight layouts are key advantages, while limitations include lower mechanical durability and potential challenges in handling during manufacturing.

Choosing Between FFC vs FPC: Selection Guidelines

Selecting between FFC (Flat Flexible Cable) and FPC (Flexible Printed Circuit) connectors depends on application requirements such as space constraints, flexibility, and signal integrity. FFC connectors are ideal for simple, low-cost applications with moderate flexibility needs, offering ease of installation and reliable contact. FPC connectors are preferred in high-density, compact electronic devices requiring complex circuit routing and enhanced durability under mechanical stress.

Future Trends in Flexible Connector Technology

Future trends in flexible connector technology emphasize enhanced durability, miniaturization, and improved signal integrity to support high-speed data transmission. Innovations in materials like advanced polymers and conductive inks are driving the evolution of FFC and FPC connectors, ensuring better flexibility and resistance to environmental stress. Your choice between FFC and FPC connectors will increasingly depend on specific application demands for performance, reliability, and ease of integration in compact electronic devices.

FFC vs FPC Connector Infographic

libmatt.com

libmatt.com