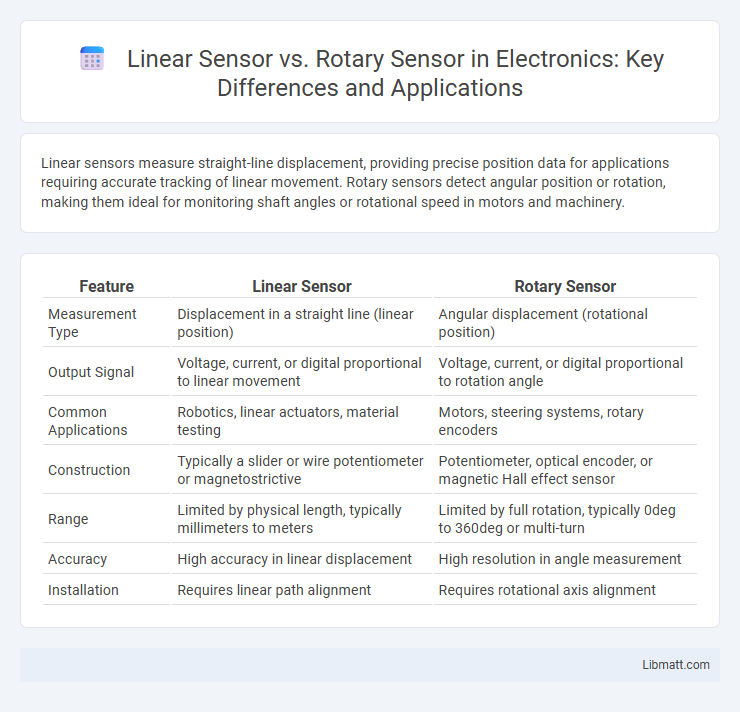

Linear sensors measure straight-line displacement, providing precise position data for applications requiring accurate tracking of linear movement. Rotary sensors detect angular position or rotation, making them ideal for monitoring shaft angles or rotational speed in motors and machinery.

Table of Comparison

| Feature | Linear Sensor | Rotary Sensor |

|---|---|---|

| Measurement Type | Displacement in a straight line (linear position) | Angular displacement (rotational position) |

| Output Signal | Voltage, current, or digital proportional to linear movement | Voltage, current, or digital proportional to rotation angle |

| Common Applications | Robotics, linear actuators, material testing | Motors, steering systems, rotary encoders |

| Construction | Typically a slider or wire potentiometer or magnetostrictive | Potentiometer, optical encoder, or magnetic Hall effect sensor |

| Range | Limited by physical length, typically millimeters to meters | Limited by full rotation, typically 0deg to 360deg or multi-turn |

| Accuracy | High accuracy in linear displacement | High resolution in angle measurement |

| Installation | Requires linear path alignment | Requires rotational axis alignment |

Introduction to Linear and Rotary Sensors

Linear sensors measure displacement or position along a straight path, converting mechanical movement into electrical signals, widely used in applications like robotics and industrial automation. Rotary sensors detect angular position or rotational movement, essential for monitoring systems such as motors and steering mechanisms. Both sensor types utilize technologies like potentiometers, encoders, or hall-effect sensors to deliver precise measurements for control and feedback systems.

Core Principles of Linear Sensors

Linear sensors operate by detecting displacement or position along a straight path, often using technologies such as potentiometric, capacitive, magnetic, or optical measurement. Their core principle involves converting physical linear movement into an electrical signal proportional to the displacement. These sensors provide precise and reliable position feedback essential in applications like automation, robotics, and industrial machinery.

Core Principles of Rotary Sensors

Rotary sensors measure angular position, velocity, or displacement by converting rotational motion into an electrical signal, typically using technologies such as optical encoders, magnetic sensors, or potentiometers. Unlike linear sensors that detect straight-line movement, rotary sensors rely on the principle of detecting changes in angular position through variations in resistance, inductance, or optical interruption. Your choice between linear and rotary sensors depends on whether your application requires precise measurement of rotation or linear displacement.

Key Applications of Linear Sensors

Linear sensors are commonly used in applications requiring precise measurement of displacement or position along a straight path, such as in industrial automation for monitoring hydraulic cylinder position, in robotics for actuating linear movements, and in automotive systems for throttle position sensing. These sensors offer high accuracy and reliability in environments where detecting linear motion is critical to maintaining operational efficiency and safety. Your choice of a linear sensor ensures optimal performance in tasks involving dimensional control and real-time feedback in manufacturing processes.

Key Applications of Rotary Sensors

Rotary sensors are widely used in robotics for precise angle measurement, enabling accurate control of arm positioning and movement. In automotive systems, they monitor steering wheel rotation and throttle position, ensuring safety and performance optimization. Industrial machinery relies on rotary sensors for motor speed feedback and shaft angle detection, crucial for automation and process control.

Linear vs Rotary Sensors: Accuracy and Precision

Linear sensors typically offer higher accuracy and precision in measuring straight-line displacement due to their direct correlation with physical movement along one axis. Rotary sensors measure angular displacement and can provide precise rotational position data, but their accuracy may be affected by factors such as gear backlash or encoder resolution. Choosing between linear and rotary sensors depends on the specific application requirements for spatial measurement type and tolerance level.

Installation and Integration Differences

Linear sensors require precise alignment along a straight path for accurate measurement, often demanding more space and careful mounting compared to rotary sensors. Rotary sensors integrate directly onto rotating shafts or shafts coupled with rotating elements, offering simpler installation with fewer alignment constraints. The integration of rotary sensors into compact mechanical assemblies is generally easier due to their cylindrical form factor and standardized mounting options.

Cost Comparison: Linear vs Rotary Sensors

Linear sensors generally have a higher cost than rotary sensors due to their complex design and precision measurement capabilities in linear displacement applications. Rotary sensors tend to be more affordable because they are simpler in construction and are widely used for angular position feedback in motors and rotary systems. Cost effectiveness depends on the application requirements, with rotary sensors often preferred for budget-sensitive projects and linear sensors chosen for accuracy-critical tasks.

Pros and Cons of Linear and Rotary Sensors

Linear sensors provide precise measurement of straight-line displacement, offering high accuracy and simplicity in applications like robotics and automation; however, they are limited by their range and require direct physical alignment with the object. Rotary sensors excel in detecting angular position and rotational speed, commonly used in motors and control systems, with advantages in continuous measurement but can suffer from noise and complexity in calibration. Choosing between linear and rotary sensors depends on the specific motion type, required precision, environmental conditions, and system integration needs.

Choosing the Right Sensor for Your Application

Selecting the right sensor depends on the motion type and spatial constraints of your application. Linear sensors measure straight-line displacement with high precision, ideal for applications requiring accurate position feedback over a defined path, while rotary sensors capture angular rotation, making them suitable for monitoring shaft position or rotary movements. Understanding your system's movement requirements ensures optimal sensor performance, enhancing accuracy and reliability in your project.

Linear sensor vs Rotary sensor Infographic

libmatt.com

libmatt.com