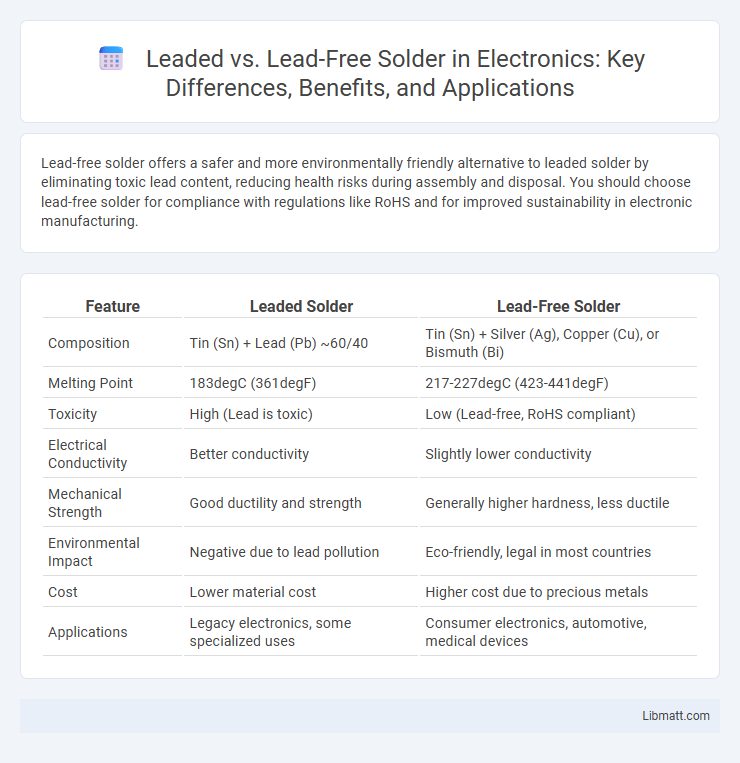

Lead-free solder offers a safer and more environmentally friendly alternative to leaded solder by eliminating toxic lead content, reducing health risks during assembly and disposal. You should choose lead-free solder for compliance with regulations like RoHS and for improved sustainability in electronic manufacturing.

Table of Comparison

| Feature | Leaded Solder | Lead-Free Solder |

|---|---|---|

| Composition | Tin (Sn) + Lead (Pb) ~60/40 | Tin (Sn) + Silver (Ag), Copper (Cu), or Bismuth (Bi) |

| Melting Point | 183degC (361degF) | 217-227degC (423-441degF) |

| Toxicity | High (Lead is toxic) | Low (Lead-free, RoHS compliant) |

| Electrical Conductivity | Better conductivity | Slightly lower conductivity |

| Mechanical Strength | Good ductility and strength | Generally higher hardness, less ductile |

| Environmental Impact | Negative due to lead pollution | Eco-friendly, legal in most countries |

| Cost | Lower material cost | Higher cost due to precious metals |

| Applications | Legacy electronics, some specialized uses | Consumer electronics, automotive, medical devices |

Introduction to Soldering Alloys

Lead-free solder alloys primarily consist of tin combined with silver, copper, or bismuth, offering an environmentally friendly alternative to traditional leaded solders, which typically contain around 60% tin and 40% lead. The transition to lead-free solders has been driven by regulations such as RoHS, emphasizing the importance of understanding alloy composition for optimal melting points and mechanical strength. Selecting the right solder alloy impacts your electronics' reliability and compliance with health and safety standards.

What is Leaded Solder?

Leaded solder is an alloy primarily composed of tin and lead, typically in a 60/40 or 63/37 ratio, renowned for its low melting point and excellent electrical conductivity. This type of solder has been widely used in electronics manufacturing due to its reliable wetting properties and strong mechanical bonds on metal surfaces. When selecting materials for your soldering projects, understanding the characteristics of leaded solder helps ensure optimal performance and durability in electronic connections.

Key Characteristics of Lead-Free Solder

Lead-free solder features a higher melting point typically ranging from 217degC to 227degC, improving thermal stability for electronic components during assembly. It contains a mix of tin, silver, and copper, eliminating health and environmental hazards associated with lead. Your choice of lead-free solder ensures compliance with RoHS regulations while maintaining strong mechanical strength and reliable electrical conductivity.

Melting Points: Leaded vs Lead-Free Solder

Leaded solder typically melts at a lower temperature, around 183degC (361degF), compared to lead-free solder, which generally melts between 217degC and 227degC (423degF to 441degF). The lower melting point of leaded solder allows for easier soldering with less thermal stress on electronic components. Lead-free solder, often composed of tin, silver, and copper alloys, requires higher heat, making it more suitable for RoHS-compliant manufacturing but potentially challenging for sensitive components.

Environmental and Health Implications

Leaded solder contains toxic substances like lead, posing significant health risks such as neurotoxicity and developmental issues when exposed over time. Lead-free solder, typically composed of tin, silver, and copper, reduces environmental contamination and is safer for manufacturing workers and end-users. Choosing lead-free solder improves Your products' eco-friendliness and compliance with global regulations like RoHS, promoting sustainable electronics production.

Performance and Reliability Comparison

Lead-free solder offers improved environmental safety but typically has a higher melting point and slightly reduced wettability compared to leaded solder, affecting ease of use. Leaded solder provides excellent performance with lower melting temperatures and superior joint reliability under thermal cycling, making it preferred for critical applications. Your choice impacts long-term device durability and compliance with environmental regulations like RoHS.

Regulatory Standards and Compliance

Regulatory standards for solder materials vary globally, with lead-free solder complying with RoHS (Restriction of Hazardous Substances) directives in regions like the European Union, restricting lead content to minimize environmental and health risks. Leaded solder, containing up to 40% lead, is increasingly phased out in commercial electronics due to its toxicity and regulatory non-compliance in many industries. Your choice between leaded and lead-free solder impacts compliance with environmental laws and industry certification requirements, influencing product marketability and safety standards.

Applications and Industry Preferences

Lead-free solder is predominantly used in electronics manufacturing to comply with environmental regulations like RoHS, ensuring safety in consumer devices, automotive electronics, and medical equipment. Leaded solder remains preferred in aerospace, defense, and military applications due to its lower melting point and superior mechanical strength under extreme conditions. Industrial sectors prioritize lead-free alternatives for mass production to reduce hazardous waste, while specialty electronics often rely on leaded solder for durability and reliability in high-stress environments.

Soldering Techniques and Best Practices

Leaded solder, typically composed of tin and lead (Sn63Pb37), offers a lower melting point around 183degC, enabling easier flow and stronger joints in traditional soldering techniques. Lead-free solder, primarily made with tin, silver, and copper (SAC alloys), requires precise temperature control near 217-221degC to prevent thermal damage and ensure reliable wetting on circuit board pads. Best practices for both involve using appropriate flux types, maintaining clean surfaces, and employing controlled heating methods such as temperature-regulated soldering irons or reflow ovens to optimize joint integrity and minimize defects like cold solder joints or bridging.

Choosing the Right Solder for Your Project

Choosing the right solder for your project depends on factors such as temperature sensitivity, environmental regulations, and electrical performance requirements. Lead-free solder, typically composed of tin, silver, and copper, offers better environmental compliance and durability but requires higher melting temperatures. Leaded solder, with its lower melting point and excellent wetting properties, remains preferred for sensitive electronics and precise work despite stricter regulations.

Leaded vs Lead-free solder Infographic

libmatt.com

libmatt.com