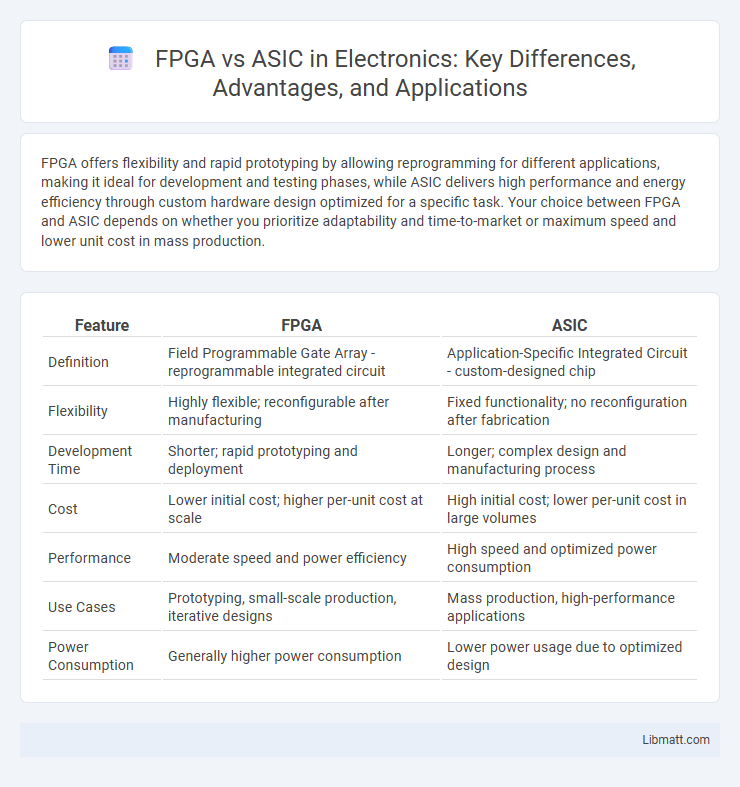

FPGA offers flexibility and rapid prototyping by allowing reprogramming for different applications, making it ideal for development and testing phases, while ASIC delivers high performance and energy efficiency through custom hardware design optimized for a specific task. Your choice between FPGA and ASIC depends on whether you prioritize adaptability and time-to-market or maximum speed and lower unit cost in mass production.

Table of Comparison

| Feature | FPGA | ASIC |

|---|---|---|

| Definition | Field Programmable Gate Array - reprogrammable integrated circuit | Application-Specific Integrated Circuit - custom-designed chip |

| Flexibility | Highly flexible; reconfigurable after manufacturing | Fixed functionality; no reconfiguration after fabrication |

| Development Time | Shorter; rapid prototyping and deployment | Longer; complex design and manufacturing process |

| Cost | Lower initial cost; higher per-unit cost at scale | High initial cost; lower per-unit cost in large volumes |

| Performance | Moderate speed and power efficiency | High speed and optimized power consumption |

| Use Cases | Prototyping, small-scale production, iterative designs | Mass production, high-performance applications |

| Power Consumption | Generally higher power consumption | Lower power usage due to optimized design |

Introduction to FPGA and ASIC

Field-Programmable Gate Arrays (FPGAs) are integrated circuits designed for post-manufacturing programmability, allowing for versatile hardware customization through configurable logic blocks and interconnects. Application-Specific Integrated Circuits (ASICs) are custom-designed chips tailored for a specific application, optimizing performance, power efficiency, and cost at scale by hardwiring the required logic. FPGA's flexibility contrasts with ASIC's fixed-function design, making each suitable for different phases of product development and deployment scenarios.

Definition and Core Differences

Field-Programmable Gate Arrays (FPGAs) are integrated circuits designed for flexibility, allowing hardware configuration after manufacturing through programming, while Application-Specific Integrated Circuits (ASICs) are custom-built chips optimized for a particular application with fixed functionality. The core difference lies in adaptability and development time; FPGAs offer rapid prototyping and reconfigurability at the cost of lower performance and higher unit price, whereas ASICs provide superior performance, power efficiency, and lower production cost in volume but require longer design cycles and lack post-fabrication modifications. FPGA architectures use configurable logic blocks and interconnects, whereas ASICs feature custom-designed logic cells tailored for specific tasks, influencing the trade-offs between design flexibility and optimal hardware efficiency.

Design Flexibility and Customization

FPGA offers superior design flexibility with its reprogrammable architecture, allowing rapid prototyping and iterative development, which is ideal for evolving project requirements. ASIC provides high customization by enabling the creation of application-specific circuits tailored for maximum performance and power efficiency but lacks post-fabrication reconfigurability. Your choice depends on whether flexibility or optimized, fixed-function performance is the priority for your application.

Performance and Speed Comparison

FPGAs offer flexibility with reconfigurable logic blocks but typically operate at lower speeds compared to ASICs, which are custom-designed for maximum performance in specific tasks. ASICs provide higher clock frequencies, lower latency, and greater throughput due to their optimized, application-specific architecture. Your choice between FPGA and ASIC impacts the performance and speed outcomes depending on your system's requirements for adaptability versus raw processing power.

Power Consumption and Efficiency

FPGA devices typically consume more power than ASICs due to their programmable architecture, which includes configurable logic blocks and routing resources that add overhead. ASICs achieve greater power efficiency by tailoring the silicon design specifically to the application, minimizing unnecessary circuitry. For your applications requiring low power consumption and high efficiency, ASICs are generally the preferred choice despite longer development cycles.

Cost Analysis: Development and Production

FPGA development incurs lower initial costs due to its reprogrammable nature and absence of expensive fabrication processes, making it ideal for prototyping and low-volume production. ASICs demand substantial upfront investment in design, mask creation, and manufacturing, but their per-unit production cost decreases significantly with high-volume output. The overall cost-effectiveness depends on production scale, with FPGAs favored for small runs and ASICs preferred for mass deployment due to optimized performance and unit cost reduction.

Time-to-Market Considerations

FPGA offers significantly faster time-to-market due to its reprogrammable nature, enabling rapid prototyping and iterative design changes without manufacturing delays. In contrast, ASIC development involves lengthy design validation, fabrication, and testing cycles, often extending timelines by several months or more. Startups and projects requiring flexibility benefit from FPGA's accelerated deployment, while ASIC suits high-volume production once time constraints are less critical.

Scalability and Volume Production

FPGAs offer high scalability with the ability to reconfigure hardware for various applications, making them ideal for low to medium volume production or prototyping. ASICs provide unmatched efficiency and performance in volume production due to their fixed hardware design optimized for specific tasks. For large-scale manufacturing, ASICs reduce unit costs significantly compared to FPGA's higher per-unit cost despite their flexibility.

Applications and Use Cases

FPGAs are ideal for prototyping, custom signal processing, and applications requiring frequent updates, such as telecommunications, aerospace, and defense systems. ASICs offer superior performance and power efficiency for mass-produced products like smartphones, consumer electronics, and high-volume integrated circuits. Industries prioritize FPGAs for flexibility and rapid deployment, while ASICs are chosen for optimized scalability and cost-effectiveness in large-scale manufacturing.

Future Trends in FPGA and ASIC Technology

Emerging trends in FPGA technology emphasize enhanced integration of AI accelerators and increased use of heterogeneous computing architectures to boost flexibility and performance. ASIC development is moving towards more energy-efficient designs through advanced process nodes and specialized AI hardware, targeting high-volume, cost-effective production. Both technologies are converging on domain-specific optimizations, with FPGA offering rapid prototyping capabilities and ASIC providing superior performance and power efficiency for large-scale deployment.

FPGA vs ASIC Infographic

libmatt.com

libmatt.com