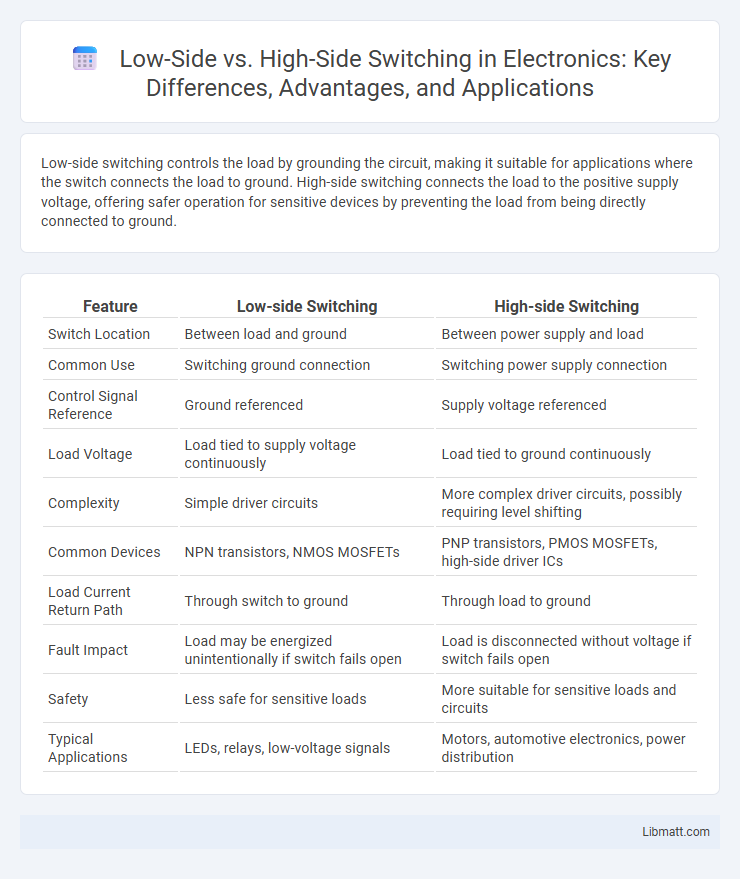

Low-side switching controls the load by grounding the circuit, making it suitable for applications where the switch connects the load to ground. High-side switching connects the load to the positive supply voltage, offering safer operation for sensitive devices by preventing the load from being directly connected to ground.

Table of Comparison

| Feature | Low-side Switching | High-side Switching |

|---|---|---|

| Switch Location | Between load and ground | Between power supply and load |

| Common Use | Switching ground connection | Switching power supply connection |

| Control Signal Reference | Ground referenced | Supply voltage referenced |

| Load Voltage | Load tied to supply voltage continuously | Load tied to ground continuously |

| Complexity | Simple driver circuits | More complex driver circuits, possibly requiring level shifting |

| Common Devices | NPN transistors, NMOS MOSFETs | PNP transistors, PMOS MOSFETs, high-side driver ICs |

| Load Current Return Path | Through switch to ground | Through load to ground |

| Fault Impact | Load may be energized unintentionally if switch fails open | Load is disconnected without voltage if switch fails open |

| Safety | Less safe for sensitive loads | More suitable for sensitive loads and circuits |

| Typical Applications | LEDs, relays, low-voltage signals | Motors, automotive electronics, power distribution |

Introduction to Low-Side and High-Side Switching

Low-side switching controls the connection between the load and ground, turning devices on or off by switching the negative side of the load. High-side switching manages power by connecting or disconnecting the positive supply voltage to the load, often requiring specialized drivers for safe operation. Understanding these methods helps optimize your circuit design for efficiency, safety, and control depending on load requirements and system configuration.

Basic Principles of Switching

Low-side switching controls the load by connecting the ground side, allowing current to flow from the power supply through the load to the switch. High-side switching controls the load by connecting the power supply side, enabling current to flow from the switch through the load to ground. Understanding these basic principles helps you choose the appropriate switching method for your circuit's safety and performance.

What is Low-Side Switching?

Low-side switching is a technique where the switching device is placed between the load and ground, allowing control of the current flow by connecting or disconnecting the load from ground. This method is commonly used with NPN transistors or N-channel MOSFETs due to their efficient switching and lower on-resistance when connected to ground. Low-side switching offers simpler circuit design and cost-effectiveness but may pose challenges in certain applications requiring precise ground referencing or safety isolation.

What is High-Side Switching?

High-side switching refers to controlling the load by connecting it to the positive supply voltage through a switch or transistor, typically a P-channel MOSFET or a PNP transistor. This method ensures that the load return path is connected to ground, enhancing safety and minimizing ground reference issues. Understanding high-side switching is crucial for designing circuits where the control signal shares the same ground as the load, protecting your components from potential damage.

Key Differences Between Low-Side and High-Side Switching

Low-side switching connects the load to the positive supply and switches the ground line, while high-side switching connects the load to ground and switches the positive supply line. Low-side switches are easier to implement with common NPN transistors or N-channel MOSFETs but may introduce ground reference issues, whereas high-side switches use PNP transistors or P-channel MOSFETs to safely control the power supply to the load, maintaining proper ground reference. Your choice between low-side and high-side switching depends on the application's need for load isolation, safety, and voltage control.

Applications of Low-Side Switching

Low-side switching is commonly used in applications where controlling the ground path of a load is sufficient, such as in LED lighting, motor control, and relay activation. This method simplifies the driving circuitry by switching the connection to ground rather than the positive supply, making it ideal for low-voltage DC systems. Your designs benefit from easier implementation and cost-effective components when using low-side switching for loads that do not require high-side switching protection.

Applications of High-Side Switching

High-side switching is commonly used in automotive and industrial applications where the load must be connected to the positive voltage supply for safety and accurate control. Your circuits benefit from high-side switches when controlling devices like motors, LEDs, or heating elements that require reliable voltage referencing and protection from ground faults. This switching method ensures efficient power management and enhances system reliability in complex electronic designs.

Advantages and Disadvantages of Each Method

Low-side switching offers simpler circuit design and cost-effectiveness by connecting the load to the positive voltage and switching the ground, but it can cause ground reference issues and may not be suitable for controlling loads with a negative ground. High-side switching provides safer load control by switching the positive supply, preventing potential ground loops and ensuring the load is disconnected from the power source, yet requires more complex driver circuitry and often higher voltage components. Your choice depends on trade-offs between simplicity, safety, and compatibility with the specific load and system configuration.

Choosing the Right Switching Method

Choosing the right switching method depends on the specific application requirements such as load type, voltage level, and safety considerations. Low-side switching is often preferred for its simplicity and ease of implementation in controlling the ground connection, while high-side switching is essential for applications needing to control the power supply side, providing better isolation and safety. Understanding the trade-offs in control logic, current path, and potential voltage drops is crucial for optimizing circuit performance and ensuring reliable operation.

Summary and Best Practices

Low-side switching controls the load by connecting it to ground, making it simpler and cost-effective for common applications, while high-side switching connects the load to the power supply, offering better protection and suitability for sensitive loads. Best practices suggest using low-side switching for straightforward control needs with minimal interference, and high-side switching when isolating the load from ground or managing higher voltages and currents. Your choice should consider the load type, voltage levels, and safety requirements to optimize performance and reliability.

Low-side vs High-side switching Infographic

libmatt.com

libmatt.com