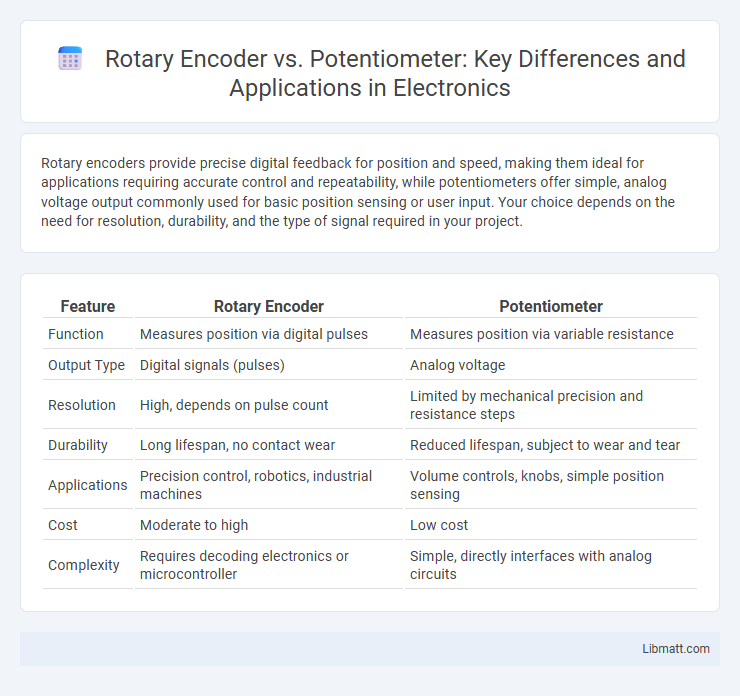

Rotary encoders provide precise digital feedback for position and speed, making them ideal for applications requiring accurate control and repeatability, while potentiometers offer simple, analog voltage output commonly used for basic position sensing or user input. Your choice depends on the need for resolution, durability, and the type of signal required in your project.

Table of Comparison

| Feature | Rotary Encoder | Potentiometer |

|---|---|---|

| Function | Measures position via digital pulses | Measures position via variable resistance |

| Output Type | Digital signals (pulses) | Analog voltage |

| Resolution | High, depends on pulse count | Limited by mechanical precision and resistance steps |

| Durability | Long lifespan, no contact wear | Reduced lifespan, subject to wear and tear |

| Applications | Precision control, robotics, industrial machines | Volume controls, knobs, simple position sensing |

| Cost | Moderate to high | Low cost |

| Complexity | Requires decoding electronics or microcontroller | Simple, directly interfaces with analog circuits |

Introduction to Rotary Encoders and Potentiometers

Rotary encoders and potentiometers are essential components for detecting angular position in electronic systems, with rotary encoders providing precise digital feedback and potentiometers offering analog resistance variation. You can use rotary encoders to measure rotational movement through pulses, ideal for applications requiring exact position tracking, while potentiometers function by varying voltage output relative to the shaft angle for simpler position sensing. Understanding the difference in their output signals and measurement techniques is crucial for selecting the right sensor for your project's control and feedback mechanisms.

How Rotary Encoders Work

Rotary encoders work by converting the angular position or motion of a shaft into digital signals through optical, magnetic, or mechanical means. They use a rotating disk with patterns that interrupt a sensor's light or magnetic field, generating pulses that indicate the position or rotation direction. Unlike potentiometers that provide a variable resistance, rotary encoders deliver precise and infinite rotation feedback essential for digital control systems.

How Potentiometers Function

Potentiometers function by varying resistance through a rotating or sliding contact over a resistive element, creating an adjustable voltage divider for precise position sensing. They provide analog output signals proportional to the angular or linear displacement, making them ideal for measuring position or adjusting levels in circuits. Your choice between a rotary encoder and a potentiometer depends on whether you need continuous position feedback or simple variable resistance control.

Key Differences Between Rotary Encoders and Potentiometers

Rotary encoders provide precise digital feedback on position, speed, and direction through incremental or absolute signals, unlike potentiometers which offer analog voltage output corresponding to position. Potentiometers rely on a resistive element and mechanical wiper, making them susceptible to wear and limited rotation angles, whereas rotary encoders use optical or magnetic sensing for durability and continuous rotation. Your choice depends on whether you need continuous, high-resolution feedback from a rotary encoder or simple, cost-effective position sensing from a potentiometer.

Accuracy and Resolution Comparison

Rotary encoders offer significantly higher accuracy and resolution compared to potentiometers due to their digital feedback mechanism, providing precise position and speed measurements. Potentiometers, relying on mechanical wipers and resistive tracks, are more prone to wear, noise, and limited resolution, often restricted to a few degrees of measurement precision. Choosing a rotary encoder enhances your system's reliability and repeatability, especially in applications demanding fine positional control.

Durability and Lifespan Analysis

Rotary encoders offer significantly higher durability and longer lifespan compared to potentiometers due to their non-contact operation, which reduces mechanical wear and tear. Potentiometers rely on physical wiper movement across resistive tracks, resulting in gradual degradation and shorter service life, often ranging from 10,000 to 100,000 cycles. High-quality rotary encoders can endure millions of rotations, making them suitable for applications demanding precise and reliable long-term performance.

Application Areas: Rotary Encoder vs Potentiometer

Rotary encoders are widely used in industrial automation, robotics, and CNC machinery for precise position and speed feedback, enabling accurate control of motor shafts and digital input devices. Potentiometers find common applications in volume controls, light dimmers, and basic position sensing in consumer electronics due to their simple analog output and ease of integration. While rotary encoders excel in high-precision and digital environments, potentiometers remain preferred for low-cost, analog sensing in less demanding scenarios.

Signal Types and Output Characteristics

Rotary encoders provide digital signals, typically in the form of quadrature pulses or binary outputs, which enable precise position and rotational direction detection. Potentiometers produce an analog voltage output proportional to the angular position of the shaft, offering continuous and variable resistance for smooth signal variation. Understanding your application's signal processing requirements helps determine whether the discrete pulses of a rotary encoder or the continuous analog output of a potentiometer best suits your control system.

Cost Considerations and Availability

Rotary encoders generally have a higher upfront cost compared to potentiometers due to their complex design and electronic components, but they offer longer lifespan and greater precision, which may reduce replacement expenses over time. Potentiometers are widely available and cost-effective for basic applications, making them a budget-friendly choice for many projects. Your decision should consider both immediate budget constraints and the long-term value in performance and durability.

Choosing the Right Sensor for Your Project

Selecting the right sensor between a rotary encoder and a potentiometer depends on your project's need for precision and durability; rotary encoders provide accurate position feedback and unlimited rotation capability, ideal for robotics and automation. Potentiometers offer simple, cost-effective angular position measurement but are limited by mechanical wear and finite rotation range, making them suitable for basic controls. Understanding your application's requirements for resolution, lifespan, and signal type will help you determine which sensor best fits your design.

Rotary Encoder vs Potentiometer Infographic

libmatt.com

libmatt.com