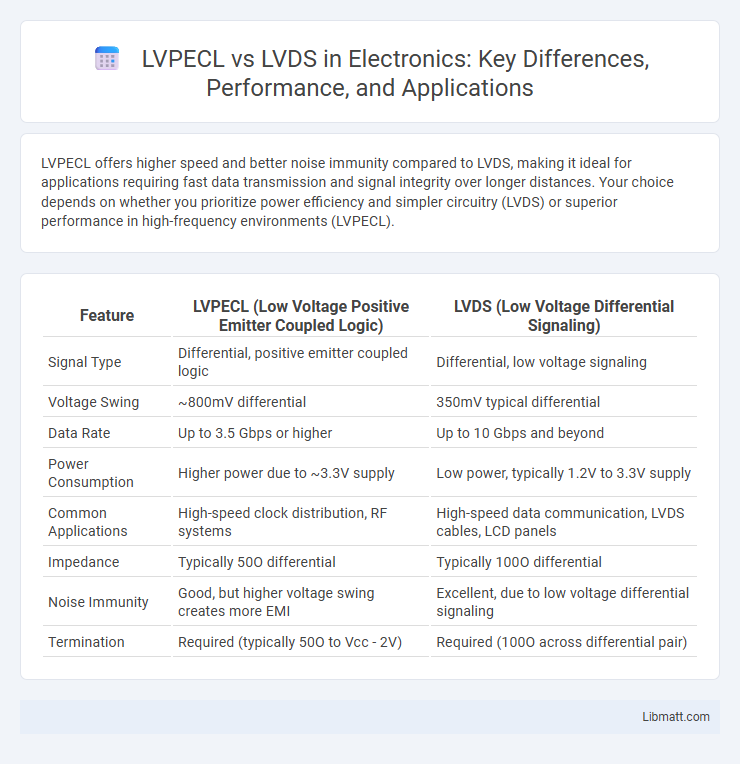

LVPECL offers higher speed and better noise immunity compared to LVDS, making it ideal for applications requiring fast data transmission and signal integrity over longer distances. Your choice depends on whether you prioritize power efficiency and simpler circuitry (LVDS) or superior performance in high-frequency environments (LVPECL).

Table of Comparison

| Feature | LVPECL (Low Voltage Positive Emitter Coupled Logic) | LVDS (Low Voltage Differential Signaling) |

|---|---|---|

| Signal Type | Differential, positive emitter coupled logic | Differential, low voltage signaling |

| Voltage Swing | ~800mV differential | 350mV typical differential |

| Data Rate | Up to 3.5 Gbps or higher | Up to 10 Gbps and beyond |

| Power Consumption | Higher power due to ~3.3V supply | Low power, typically 1.2V to 3.3V supply |

| Common Applications | High-speed clock distribution, RF systems | High-speed data communication, LVDS cables, LCD panels |

| Impedance | Typically 50O differential | Typically 100O differential |

| Noise Immunity | Good, but higher voltage swing creates more EMI | Excellent, due to low voltage differential signaling |

| Termination | Required (typically 50O to Vcc - 2V) | Required (100O across differential pair) |

Introduction to LVPECL and LVDS

LVPECL (Low Voltage Positive Emitter Coupled Logic) and LVDS (Low Voltage Differential Signaling) are high-speed, differential signaling standards widely used for data communication in digital systems. LVPECL offers faster switching speeds and higher voltage levels suitable for clock distribution and high-frequency data transfer, while LVDS provides lower power consumption and electromagnetic interference (EMI), making it ideal for long-distance and noise-sensitive applications. Your choice between LVPECL and LVDS depends on factors like signal integrity requirements, power efficiency, and application environment.

Fundamental Principles of LVPECL

LVPECL (Low Voltage Positive Emitter Coupled Logic) operates on differential signaling with a constant current source and termination resistors, providing high-speed data transmission and low noise susceptibility. Unlike LVDS, which uses low voltage swings around a common mode voltage, LVPECL swings close to the supply voltage, typically around 3.3V, enabling faster edge rates and superior jitter performance in high-frequency applications. Understanding these fundamental principles allows you to select the optimal signaling standard for your high-speed communication needs.

Understanding LVDS Signaling

LVDS (Low Voltage Differential Signaling) uses low voltage swings around 350mV over twisted-pair cables to achieve high-speed data transmission with minimal power consumption and electromagnetic interference. This differential signaling technique enhances noise immunity and supports data rates typically up to 1 Gbps, making it suitable for high-speed communication in various applications. Understanding LVDS signaling helps optimize your system's data integrity and power efficiency compared to LVPECL, which operates at higher voltage levels and power consumption.

Key Differences Between LVPECL and LVDS

LVPECL (Low Voltage Positive Emitter Coupled Logic) operates at higher voltage levels and offers faster signal transitions compared to LVDS (Low Voltage Differential Signaling), which is optimized for low power consumption and noise immunity. LVPECL uses a differential pair with a constant current source to maintain signal integrity at high frequencies, whereas LVDS uses low-voltage swing differential signaling to minimize electromagnetic interference and power use. Key differences include LVPECL's higher output voltage swings and power requirements versus LVDS's efficient, low-voltage, and low-noise signaling suitable for high-speed data transmission in power-sensitive applications.

Voltage Level Comparisons

LVPECL operates at a higher voltage level, typically around 3.3V with differential output swings of about 800mV, while LVDS functions at a lower voltage, generally 1.2V with differential swings around 350mV. The higher voltage swings in LVPECL provide better noise immunity and faster edge rates, making it suitable for high-speed applications requiring robust signal integrity. Understanding these voltage differences helps you select the appropriate standard to balance power consumption and signal performance.

Power Consumption Analysis

LVPECL (Low Voltage Positive Emitter Coupled Logic) typically consumes more power than LVDS (Low Voltage Differential Signaling) due to its higher voltage swing and bias currents, making LVDS more energy-efficient for high-speed data transmission. LVDS operates with lower voltage swings around 350 mV, minimizing power dissipation and making it ideal for applications where power consumption is critical. When optimizing Your system for low power, LVDS provides a significant advantage in reducing overall energy usage compared to LVPECL technology.

Signal Integrity and Noise Immunity

LVPECL offers superior signal integrity due to its differential signaling with higher voltage swings, reducing jitter and improving timing accuracy compared to LVDS. LVDS provides excellent noise immunity by operating at lower voltage levels and utilizing differential pairs that cancel common-mode noise, making it well-suited for electrically noisy environments. Choosing between LVPECL and LVDS depends on your system's specific requirements for signal fidelity and noise resilience.

Applications and Use Cases

LVPECL (Low Voltage Positive Emitter Coupled Logic) is widely used in high-speed communication systems and clock distribution networks requiring low jitter and high frequency performance. LVDS (Low Voltage Differential Signaling) excels in applications such as LCD panels, data communication, and high-speed data transfer where power efficiency and noise immunity are critical. Your choice between LVPECL and LVDS depends on the need for either ultra-fast signal transmission with minimal noise (LVPECL) or low power consumption and longer cable lengths (LVDS).

Design Considerations and Challenges

LVPECL offers higher speed and better signal integrity for high-frequency applications, while LVDS provides low power consumption and reduced EMI, making design decisions hinge on balancing performance with power efficiency. Designers must address LVPECL's higher power dissipation and voltage swing requirements, compared to LVDS's strict impedance matching and noise margin constraints. Your system's operating environment and signal integrity goals will dictate whether LVPECL's robust drive capabilities or LVDS's efficient differential signaling is the optimal choice.

Choosing Between LVPECL and LVDS

Choosing between LVPECL and LVDS depends on the required signal integrity and system bandwidth. LVPECL offers higher voltage swing and better noise margins, making it suitable for high-speed communications over longer distances, while LVDS provides lower power consumption and simpler PCB design due to its lower voltage levels. Evaluating factors such as power efficiency, EMI sensitivity, and transmission distance is crucial for selecting the optimal differential signaling technology.

LVPECL vs LVDS Infographic

libmatt.com

libmatt.com