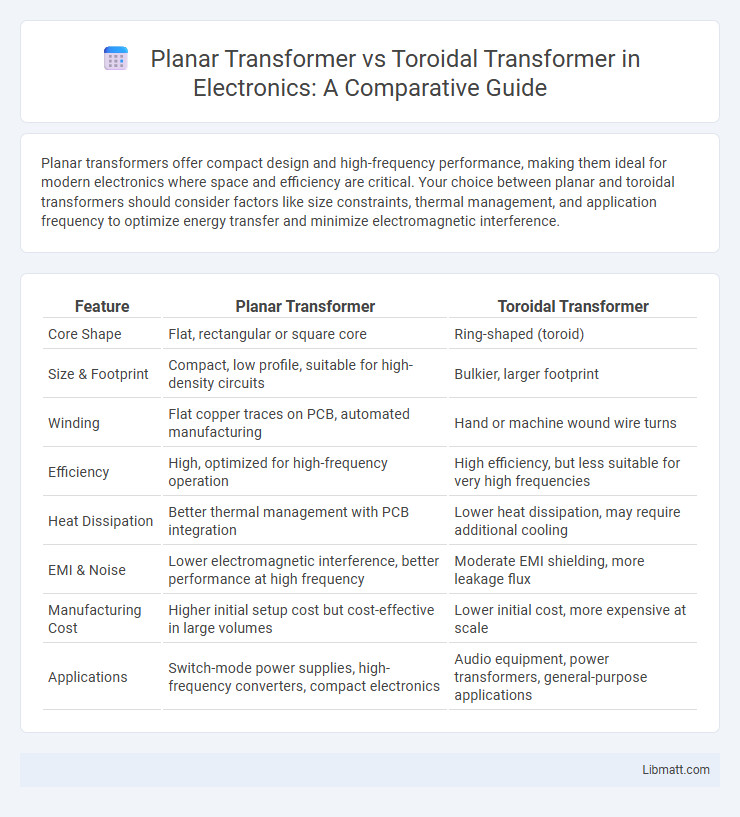

Planar transformers offer compact design and high-frequency performance, making them ideal for modern electronics where space and efficiency are critical. Your choice between planar and toroidal transformers should consider factors like size constraints, thermal management, and application frequency to optimize energy transfer and minimize electromagnetic interference.

Table of Comparison

| Feature | Planar Transformer | Toroidal Transformer |

|---|---|---|

| Core Shape | Flat, rectangular or square core | Ring-shaped (toroid) |

| Size & Footprint | Compact, low profile, suitable for high-density circuits | Bulkier, larger footprint |

| Winding | Flat copper traces on PCB, automated manufacturing | Hand or machine wound wire turns |

| Efficiency | High, optimized for high-frequency operation | High efficiency, but less suitable for very high frequencies |

| Heat Dissipation | Better thermal management with PCB integration | Lower heat dissipation, may require additional cooling |

| EMI & Noise | Lower electromagnetic interference, better performance at high frequency | Moderate EMI shielding, more leakage flux |

| Manufacturing Cost | Higher initial setup cost but cost-effective in large volumes | Lower initial cost, more expensive at scale |

| Applications | Switch-mode power supplies, high-frequency converters, compact electronics | Audio equipment, power transformers, general-purpose applications |

Introduction to Planar and Toroidal Transformers

Planar transformers utilize flat, layered windings and magnetic cores to achieve compact, lightweight designs with high efficiency and excellent thermal performance, making them ideal for high-frequency applications. Toroidal transformers feature a doughnut-shaped core that provides low electromagnetic interference and reduced core losses, commonly used in audio and power supply systems. Both transformer types offer unique advantages depending on the application requirements for size, efficiency, and electrical noise reduction.

Core Design and Construction Differences

Planar transformers feature a flat, spiral-wound core made from thin laminations, optimizing space with low profile construction suitable for high-frequency applications. Toroidal transformers utilize a donut-shaped core constructed from continuous grain-oriented steel or ferrite, providing high magnetic efficiency and reduced electromagnetic interference. Your choice between these transformers depends on the specific requirements for size, efficiency, and electromagnetic compatibility in your design.

Efficiency Comparison

Planar transformers generally offer higher efficiency than toroidal transformers due to reduced winding resistance and lower leakage inductance, which results in decreased power losses. Their compact design minimizes eddy current losses and enhances thermal management, contributing to improved energy performance in high-frequency applications. You can expect planar transformers to deliver better efficiency in power electronics where space and thermal performance are critical.

Size and Weight Considerations

Planar transformers exhibit a significantly lower profile and reduced footprint compared to toroidal transformers, making them ideal for compact electronic devices and applications where space is limited. Their lightweight design results from using thin, flat copper windings on PCB substrates, contrasting with the bulky wire windings and magnetic cores of toroidal transformers. Consequently, planar transformers enhance thermal efficiency and simplify automated manufacturing processes, offering advantages in both size and weight over traditional toroidal transformers.

Thermal Management and Cooling

Planar transformers exhibit superior thermal management due to their low-profile, laminated design which facilitates efficient heat dissipation across a larger surface area compared to toroidal transformers. The flat winding structure allows for closer integration with heat sinks and improved airflow, resulting in enhanced cooling performance. Toroidal transformers, while compact and efficient in electromagnetic design, often encounter higher thermal resistance due to their wound core geometry, limiting cooling options and increasing the risk of localized hotspots.

Electromagnetic Interference (EMI) Performance

Planar transformers typically exhibit superior Electromagnetic Interference (EMI) performance compared to toroidal transformers due to their compact, low-profile design and tightly controlled winding geometry that minimizes electromagnetic radiation. The flat, layered winding structure in planar transformers reduces parasitic inductances and capacitances, leading to lower emissions and improved noise immunity, which is crucial in high-frequency switching applications. When optimizing your device for EMI compliance, planar transformers offer a more efficient solution by delivering enhanced electromagnetic compatibility within compact spaces.

Applications and Use Cases

Planar transformers are ideal for high-frequency applications such as power supplies in telecommunications, aerospace, and compact industrial devices due to their low profile and excellent thermal performance. Toroidal transformers find extensive use in audio equipment, medical devices, and power conditioning systems where low electromagnetic interference and high efficiency are critical. Your choice depends on whether compact design and high-frequency operation or low noise and energy efficiency better meet the demands of your specific application.

Cost and Manufacturing Complexity

Planar transformers offer lower manufacturing complexity and cost due to their automated, PCB-based assembly process, enabling precise winding patterns and reduced material usage. Toroidal transformers involve intricate winding techniques on a doughnut-shaped core, increasing labor intensity and production expenses. Overall, planar transformers are more cost-efficient for high-volume, compact applications, while toroidal transformers tend to be costlier but provide superior magnetic performance in low-volume, custom designs.

Reliability and Longevity

Planar transformers offer enhanced reliability and longevity due to their compact design, improved thermal performance, and reduced parasitic inductance, which minimize heat buildup and component stress. Toroidal transformers also provide excellent durability with their efficient magnetic flux distribution and low core losses, contributing to stable long-term operation. Choosing a planar transformer can benefit your application by delivering consistent performance in high-frequency environments, while toroidal transformers excel in lower-frequency, high-power scenarios requiring robust reliability.

Future Trends in Transformer Technology

Planar transformers are becoming increasingly favored in compact electronic devices due to their low profile, efficient heat dissipation, and compatibility with automated manufacturing processes, driving advancements in high-frequency and high-density power applications. Toroidal transformers continue to be valued for their superior magnetic efficiency and low electromagnetic interference, making them essential in audio equipment and high-precision industrial systems. Future trends emphasize integrating both technologies with advanced materials like nanocrystalline cores and AI-driven design tools to enhance energy efficiency, thermal management, and miniaturization.

Planar transformer vs Toroidal transformer Infographic

libmatt.com

libmatt.com