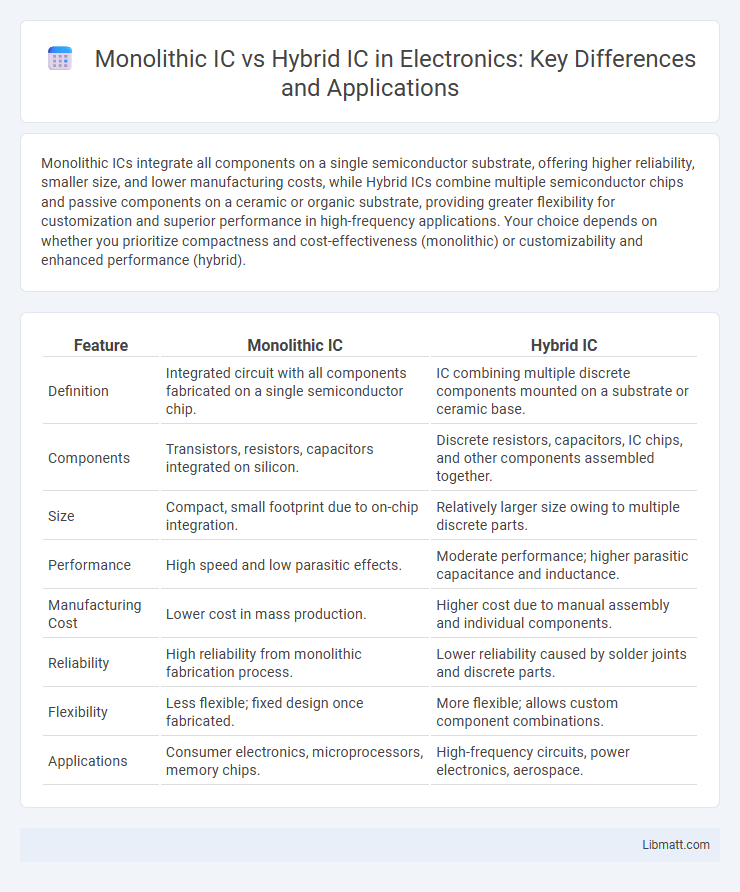

Monolithic ICs integrate all components on a single semiconductor substrate, offering higher reliability, smaller size, and lower manufacturing costs, while Hybrid ICs combine multiple semiconductor chips and passive components on a ceramic or organic substrate, providing greater flexibility for customization and superior performance in high-frequency applications. Your choice depends on whether you prioritize compactness and cost-effectiveness (monolithic) or customizability and enhanced performance (hybrid).

Table of Comparison

| Feature | Monolithic IC | Hybrid IC |

|---|---|---|

| Definition | Integrated circuit with all components fabricated on a single semiconductor chip. | IC combining multiple discrete components mounted on a substrate or ceramic base. |

| Components | Transistors, resistors, capacitors integrated on silicon. | Discrete resistors, capacitors, IC chips, and other components assembled together. |

| Size | Compact, small footprint due to on-chip integration. | Relatively larger size owing to multiple discrete parts. |

| Performance | High speed and low parasitic effects. | Moderate performance; higher parasitic capacitance and inductance. |

| Manufacturing Cost | Lower cost in mass production. | Higher cost due to manual assembly and individual components. |

| Reliability | High reliability from monolithic fabrication process. | Lower reliability caused by solder joints and discrete parts. |

| Flexibility | Less flexible; fixed design once fabricated. | More flexible; allows custom component combinations. |

| Applications | Consumer electronics, microprocessors, memory chips. | High-frequency circuits, power electronics, aerospace. |

Introduction to Integrated Circuits

Integrated circuits (ICs) are semiconductor devices that combine multiple electronic components into a single chip, enhancing performance and reducing size. Monolithic ICs are fabricated entirely on a single semiconductor substrate, providing high reliability and cost efficiency for mass production. Hybrid ICs integrate multiple discrete components on a ceramic or organic substrate, offering flexibility and enhanced performance for specialized applications.

What is a Monolithic IC?

A Monolithic IC (Integrated Circuit) is a semiconductor device where all components, including transistors, resistors, and capacitors, are fabricated directly onto a single silicon chip. This integration enables high density, improved performance, and reduced manufacturing costs compared to discrete circuits. Monolithic ICs are essential in modern electronics for applications requiring compact size and efficient functionality.

What is a Hybrid IC?

A Hybrid IC (Integrated Circuit) combines multiple semiconductor components and passive elements such as resistors and capacitors on a single substrate, offering enhanced functionality and performance. Unlike Monolithic ICs, which are fabricated entirely on one silicon chip, Hybrid ICs integrate discrete devices using various materials, allowing customization for specialized applications. This approach provides greater flexibility in design, enabling complex circuits and improved power handling in compact form factors.

Key Differences Between Monolithic and Hybrid ICs

Monolithic ICs are fabricated entirely on a single semiconductor substrate, offering high reliability, compact size, and lower production costs due to their integrated design. Hybrid ICs combine multiple semiconductor devices and passive components on a ceramic or organic substrate, allowing more flexibility in component selection but resulting in larger size and higher manufacturing complexity. Your choice depends on the application's need for integration density, cost efficiency, and customization, with monolithic ICs excelling in mass production and hybrid ICs suited for specialized, high-performance circuits.

Advantages of Monolithic ICs

Monolithic ICs offer advantages such as lower manufacturing costs due to integrated fabrication on a single silicon chip, enhanced reliability from reduced interconnections, and improved performance with faster signal processing and lower parasitic capacitance. Their compact size allows for greater circuit density, making them ideal for mass production and miniaturized electronic devices. Your projects can benefit from these durable, cost-effective, and high-speed components when choosing Monolithic ICs over Hybrid ICs.

Advantages of Hybrid ICs

Hybrid ICs offer superior customization and flexibility by integrating different semiconductor materials and discrete components on a single substrate. They provide enhanced performance in high-frequency applications and improved thermal management compared to Monolithic ICs. Your designs can benefit from the robustness and reliability of Hybrid ICs in specialized electronic systems.

Applications of Monolithic ICs

Monolithic ICs are widely used in consumer electronics, automotive systems, and communication devices due to their compact size and high reliability. These integrated circuits are ideal for applications requiring mass production and cost efficiency, such as microprocessors, memory chips, and analog signal processing. Your electronic products benefit from enhanced performance and durability when incorporating monolithic IC technology.

Applications of Hybrid ICs

Hybrid ICs find extensive applications in aerospace, military, and medical devices due to their ability to combine different semiconductor technologies on a single substrate, ensuring high reliability and performance under extreme conditions. They are widely used in RF amplifiers, power management systems, and sensor interfaces where compact size and thermal stability are critical. The versatility of hybrid ICs makes them ideal for custom solutions in instrumentation and automotive electronics.

Cost and Performance Comparison

Monolithic ICs generally offer lower production costs due to their single-chip construction, enabling mass manufacturing and economies of scale, whereas Hybrid ICs incur higher costs because of complex assembly involving multiple substrates and discrete components. Performance-wise, Monolithic ICs deliver faster operation speeds and better signal integrity due to their integrated design, while Hybrid ICs provide enhanced customization and reliability for specialized applications requiring diverse materials or high power handling. The trade-off between cost efficiency and tailored performance often determines the choice between Monolithic and Hybrid IC technologies in semiconductor design.

Future Trends in Integrated Circuit Technology

Monolithic ICs, which integrate all components on a single semiconductor substrate, are advancing with nanometer-scale fabrication and enhanced performance for future electronics. Hybrid ICs combine different materials and technologies, offering flexibility and the ability to integrate components incompatible with monolithic processes, driving innovation in specialized applications. Your choice between these will influence adaptability to emerging trends like flexible electronics, 3D integration, and heterogeneous systems.

Monolithic IC vs Hybrid IC Infographic

libmatt.com

libmatt.com