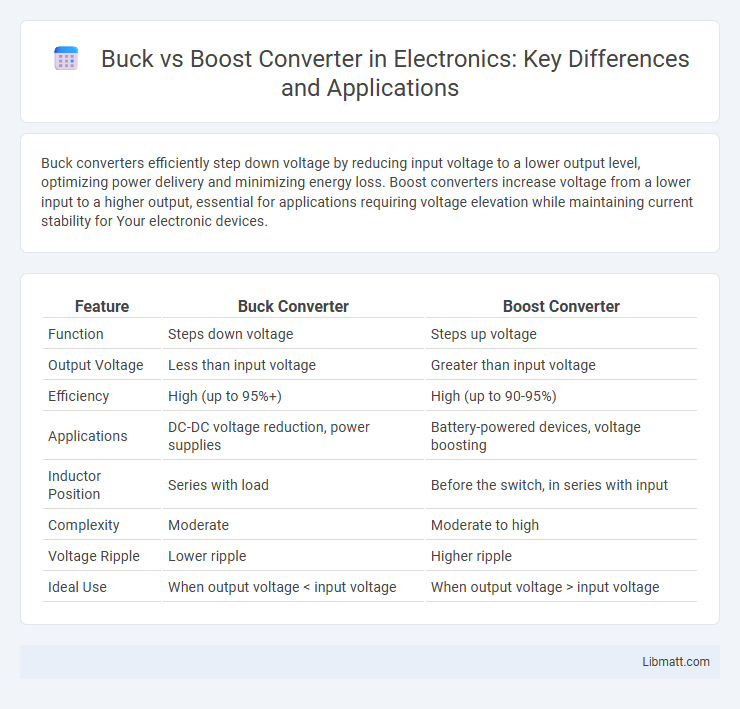

Buck converters efficiently step down voltage by reducing input voltage to a lower output level, optimizing power delivery and minimizing energy loss. Boost converters increase voltage from a lower input to a higher output, essential for applications requiring voltage elevation while maintaining current stability for Your electronic devices.

Table of Comparison

| Feature | Buck Converter | Boost Converter |

|---|---|---|

| Function | Steps down voltage | Steps up voltage |

| Output Voltage | Less than input voltage | Greater than input voltage |

| Efficiency | High (up to 95%+) | High (up to 90-95%) |

| Applications | DC-DC voltage reduction, power supplies | Battery-powered devices, voltage boosting |

| Inductor Position | Series with load | Before the switch, in series with input |

| Complexity | Moderate | Moderate to high |

| Voltage Ripple | Lower ripple | Higher ripple |

| Ideal Use | When output voltage < input voltage | When output voltage > input voltage |

Introduction to Buck and Boost Converters

Buck and Boost Converters are essential types of DC-DC converters used in power electronics to efficiently regulate voltage levels. A Buck Converter steps down voltage from a higher input to a lower output, ideal for applications requiring reduced voltage with minimal energy loss. In contrast, a Boost Converter increases voltage from a lower input to a higher output, ensuring your devices receive stable power when higher voltage is needed.

Basic Working Principles

Buck converters reduce voltage by switching a transistor on and off rapidly, storing energy in an inductor and delivering a lower average voltage to the load. Boost converters increase voltage by storing energy in an inductor while the transistor is on and releasing it to the load through a diode when the transistor switches off, resulting in a higher output voltage. Your choice depends on whether you need to efficiently step down or step up the voltage for your application.

Key Differences Between Buck and Boost Converters

Buck converters step down voltage efficiently by switching transistors and energy storage components, while boost converters increase voltage using similar components but different switching sequences. Buck converters deliver a lower output voltage than the input, ideal for battery-powered devices, whereas boost converters provide a higher output voltage, suitable for applications requiring voltage elevation. Efficiency, output voltage range, and component stress vary significantly between these converters due to their distinct operational topologies.

Applications of Buck Converters

Buck converters are widely used in applications requiring efficient voltage step-down, such as powering microcontrollers, LEDs, and battery-powered devices by reducing higher input voltage to a stable lower output voltage. They play a critical role in power management for laptops, smartphones, and embedded systems where energy efficiency and heat dissipation are crucial. Your choice of a buck converter ensures optimized performance and extended battery life in portable electronics and renewable energy systems.

Applications of Boost Converters

Boost converters are widely used in applications requiring voltage step-up from a lower input voltage, such as battery-powered devices, where maximizing energy efficiency is critical. These converters are integral to renewable energy systems like solar panels to increase output voltage for grid compatibility or battery charging. Electric vehicles also utilize boost converters to elevate battery voltage for efficient motor operation and auxiliary systems.

Efficiency Comparison

Buck converters typically achieve higher efficiency than boost converters due to their simpler topology and lower voltage stress on components, often exceeding 90% under optimal load conditions. Boost converters experience efficiency losses caused by increased conduction and switching losses, especially at high output voltage ratios. Your choice between buck and boost converters should consider these efficiency differences alongside specific voltage requirements for optimal power management.

Component Selection Considerations

Component selection for Buck vs Boost converters hinges on factors like voltage rating, current capacity, and switching frequency to ensure efficiency and reliability. Inductors with low DC resistance and appropriate saturation current are crucial for minimizing power loss in both topologies, while capacitors must handle ripple current and voltage stress specific to each converter type. Your choice of MOSFETs or diodes depends on conduction and switching losses, making it essential to balance thermal performance and cost for optimal converter operation.

Output Voltage Regulation

Buck converters provide precise output voltage regulation by stepping down the input voltage to a lower, stable level using a controlled duty cycle. Boost converters regulate output voltage by increasing the input voltage through energy storage in an inductor, ensuring a consistently higher output than the input voltage. Your choice depends on whether you need a voltage step-down or step-up with accurate and stable regulation for your application.

Advantages and Disadvantages

Buck converters offer high efficiency and simplicity in stepping down voltage, making them ideal for battery-powered applications with limited heat dissipation. Boost converters efficiently increase voltage from lower input sources but can be more complex and generate higher electromagnetic interference (EMI). Both converters require careful consideration of switching frequency, input/output voltage range, and load conditions to optimize performance and minimize losses.

Choosing the Right Converter for Your Application

Selecting the right converter depends on your application's voltage requirements and efficiency needs. Buck converters efficiently step down voltage for low-voltage devices, while boost converters increase voltage when the supply voltage is insufficient. Assessing input-output voltage ranges and current demands ensures optimal performance and power management in your design.

Buck vs Boost Converter Infographic

libmatt.com

libmatt.com