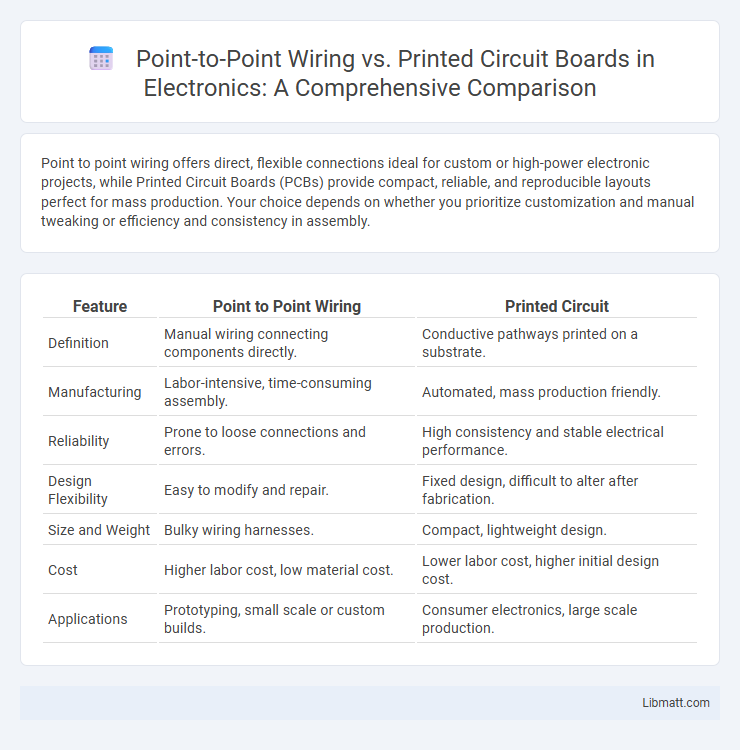

Point to point wiring offers direct, flexible connections ideal for custom or high-power electronic projects, while Printed Circuit Boards (PCBs) provide compact, reliable, and reproducible layouts perfect for mass production. Your choice depends on whether you prioritize customization and manual tweaking or efficiency and consistency in assembly.

Table of Comparison

| Feature | Point to Point Wiring | Printed Circuit |

|---|---|---|

| Definition | Manual wiring connecting components directly. | Conductive pathways printed on a substrate. |

| Manufacturing | Labor-intensive, time-consuming assembly. | Automated, mass production friendly. |

| Reliability | Prone to loose connections and errors. | High consistency and stable electrical performance. |

| Design Flexibility | Easy to modify and repair. | Fixed design, difficult to alter after fabrication. |

| Size and Weight | Bulky wiring harnesses. | Compact, lightweight design. |

| Cost | Higher labor cost, low material cost. | Lower labor cost, higher initial design cost. |

| Applications | Prototyping, small scale or custom builds. | Consumer electronics, large scale production. |

Introduction to Point-to-Point Wiring and Printed Circuits

Point-to-point wiring connects components directly using wires, offering flexible, custom circuit layouts often found in vintage electronics and prototypes. Printed circuit boards (PCBs) use etched conductive paths on insulating material, providing compact, reliable, and mass-producible circuits essential for modern devices. Understanding these methods helps you choose between handcrafted precision and automated efficiency for your electronic projects.

Historical Evolution of Circuit Assembly Techniques

Point to point wiring dominated early electronic assembly, with components manually connected by wires to ensure reliable circuits in vacuum tube radios and early computers. The advent of printed circuit boards (PCBs) in the mid-20th century revolutionized manufacturing, enabling automated production, compact design, and consistent electrical performance. This transition marked a significant technological evolution, driving advancements in electronics by reducing assembly time and enhancing circuit complexity.

Design Principles: Point-to-Point vs Printed Circuits

Point-to-point wiring relies on direct electrical connections between components, emphasizing flexibility in design but requiring meticulous manual assembly and limiting scalability. Printed circuit boards (PCBs) utilize predefined copper pathways etched onto insulated substrates, enabling precise, repeatable layouts that enhance signal integrity and reduce interference. The design principles of PCBs prioritize optimization for automated production and compactness, whereas point-to-point wiring favors custom, low-volume, or prototyping applications with simpler circuit configurations.

Materials Used in Point-to-Point Wiring and Printed Circuits

Point-to-point wiring typically uses insulated copper wires, often made of stranded or solid conductors, connected via soldered terminals or eyelets, favoring materials like cotton or PVC insulation for durability and flexibility. Printed circuit boards (PCBs) utilize laminated substrates such as fiberglass-reinforced epoxy resin (FR-4) combined with etched copper layers to create precise conductive pathways. The choice of materials in PCBs ensures mechanical stability, high thermal resistance, and excellent electrical conductivity, whereas point-to-point wiring excels in customizability and ease of repair.

Performance and Reliability Comparison

Point-to-point wiring offers superior electrical performance with minimal signal interference due to shorter, direct connections, enhancing reliability in high-frequency or high-power applications. Printed circuit boards (PCBs) provide consistent reproducibility and mechanical stability, which improves long-term reliability but can suffer from signal crosstalk and parasitic inductance affecting performance in sensitive circuits. Your choice between point-to-point wiring and PCBs will depend on the specific performance demands and reliability requirements of your electronic project.

Manufacturing Process Differences

Point to Point wiring involves manually connecting individual components using wires, making the manufacturing process labor-intensive and prone to human error. Printed Circuit Boards (PCBs) use automated photolithography and etching techniques to create precise copper pathways, enabling faster, more consistent mass production. Your choice between these methods impacts production time, reliability, and scalability in electronic assembly.

Cost Analysis and Scalability Considerations

Point to Point wiring typically incurs higher labor costs due to manual assembly, making it less cost-effective for large-scale production compared to Printed Circuit Boards (PCBs), which benefit from automated manufacturing processes that reduce unit costs significantly. PCBs offer superior scalability by enabling mass production with consistent quality, whereas Point to Point wiring struggles with variability and time-consuming assembly. Your decision on wiring type should consider initial cost, volume requirements, and long-term scalability to optimize budget and production efficiency.

Application Areas: Where Each Method Excels

Point to Point wiring excels in high-frequency and high-voltage applications such as vintage audio equipment, aerospace, and military systems due to its superior reliability and ease of modification. Printed Circuit Boards (PCBs) dominate mass production in consumer electronics, automotive controls, and computer hardware thanks to their precision, compact design, and efficient assembly process. The choice between Point to Point wiring and PCBs depends on factors like production volume, environmental conditions, and performance requirements.

Maintenance, Repairs, and Flexibility

Point to point wiring offers easier maintenance and repairs due to accessible individual connections, allowing quick identification and replacement of faulty components. Printed circuit boards (PCBs) provide less flexibility for modifications but ensure consistent performance with fewer wiring errors. In complex or high-volume production, PCBs minimize repair frequency, while point to point wiring excels in prototypes and customizable equipment.

Future Trends in Circuit Fabrication Technologies

Future trends in circuit fabrication technologies emphasize advanced methods like additive manufacturing and flexible electronics, moving beyond traditional point-to-point wiring and printed circuit boards (PCBs). Innovations such as 3D printing enable more complex, lightweight, and compact circuit designs with enhanced performance and durability. Your projects will benefit from increased customization options and faster prototyping speeds as these emerging techniques mature and integrate into mainstream manufacturing.

Point to Point Wiring vs Printed Circuit Infographic

libmatt.com

libmatt.com